Cluster-smab.de

Lithium-ion batteries –

The bubble bursts

Stuttgart, October 2012

Consolidation in the lithium-ion battery (LiB) market is inevitable –

Stakeholders need to revise their strategies

The large-format lithium-ion cell market will face overcapacity and price wars:

- Demand is lower than expected

- A lot of capacity has been built up – but new equipment to be installed will be

- Prices are down to 180 and 200 EUR/kWH in 2014/2015

Bottom-up calculations show that with an expected EBIT margin at or below 5%,

"early movers" in particular cannot generate enough EBIT to finance their cost

of capital

New developments on the material side (mainly cathodes, electrolytes/separators)

as well as in production technologies will lead to further cost reductions – but

require more cash for introduction and industrialization

Therefore only the already large players or companies will survive the shakeout,

as their parent companies might be willing to provide the business with sufficient

capital

That's why cell manufacturers as well as their customers – the OEMs – need to

rethink their strategies

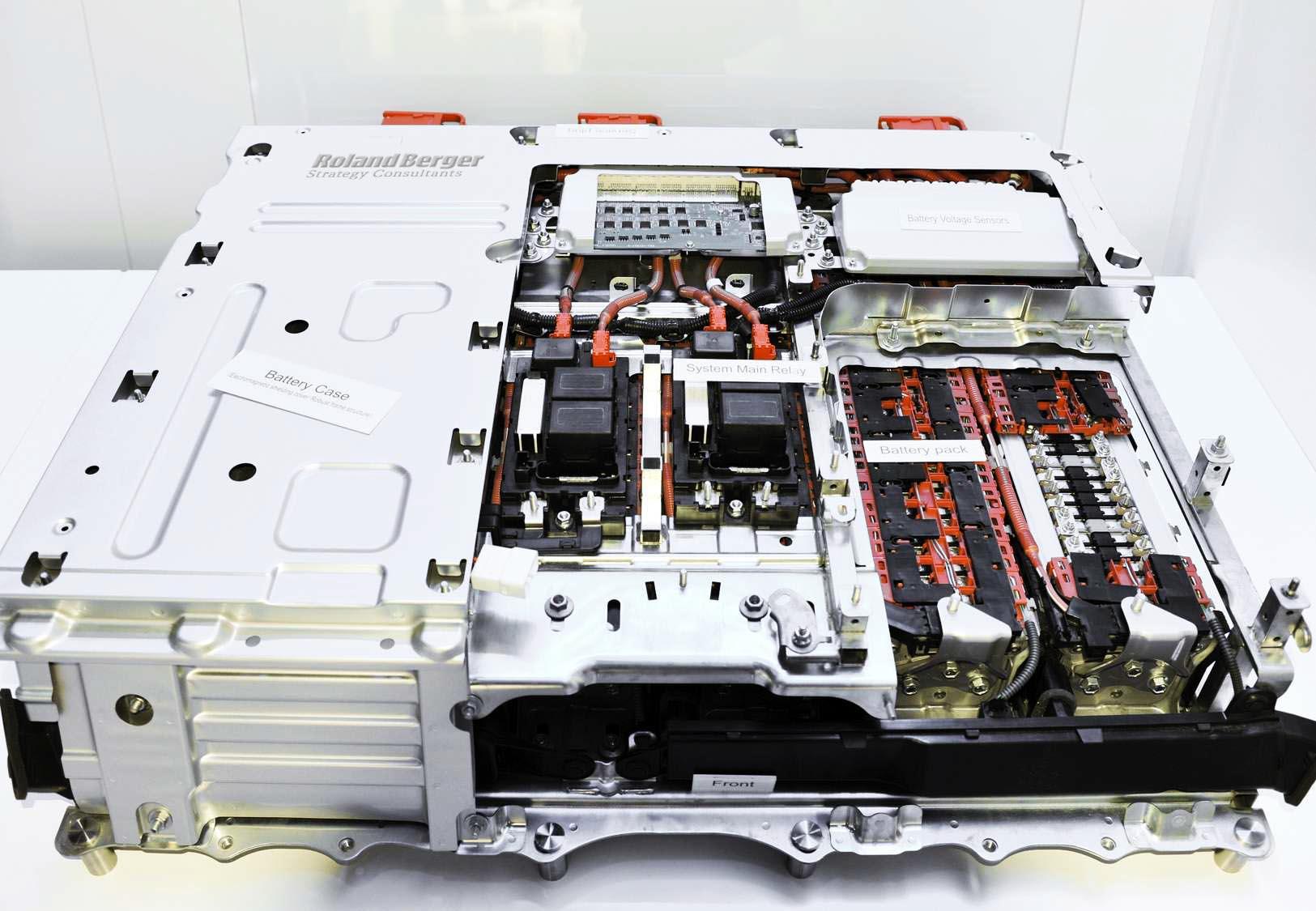

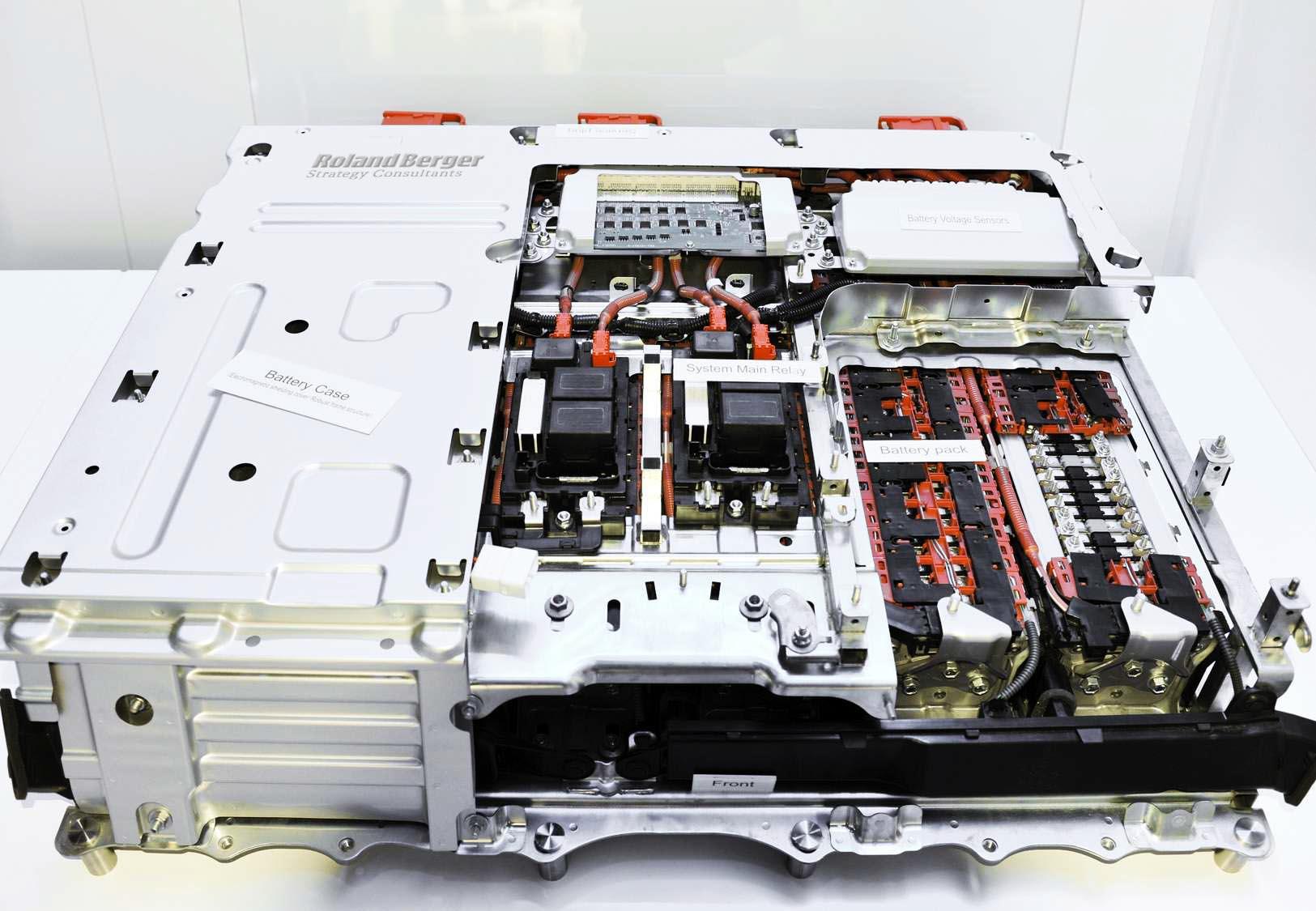

Source: Roland Berger

OEMs will increase xEVs sales significantly in the short term –

Toyota will remain the main player

OEMs xEV sales plans by xEV type [m units]

Hybrid light

Comments

• Figures are a

summary of OEMs'

sales targets for their xEV programs

• They do not include

sub-A-segment vehicles (vehicles not classified as

"passenger cars")

Sales targets tend to

be on the optimistic

side – but were not

adjusted by Roland Berger

OEMs excl. Toyota

xx CAGR 2011-2015

Source: Roland Berger

However, in one 2020 scenario, xEVs will represent only a minor

share of powertrains in EU, US and China – Introduction delayed

Base scenario: xEV market share in the EU, US and China, 2020 [%]

COMMENTS

• Market share calculated based on an

assessment of push (legislation-driven) and

pull (customer-driven) factors for xEVs in the EU, US and China

• The market shares shown represent the

minimum required xEV share to meet push and pull in each region – Higher xEV market

shares are possible and even likely

• The EU's xEV market share achieves the level

required to meet EU CO emissions targets in

an aggressive scenario regarding ICE optimization and driving resistance reduction

• The US's and China's xEV market shares are

primarily required to fulfill pull factors for xEVs

• Further legislative action might increase share • Japanese/Korean figures expected to fall

between the US and EU

Conventional incl. Start-Stop

Source: Roland Berger

The EU's xEV market is primarily legislation-driven – The US and

China are driven primarily by customer pull

Summary of push and pull factors for xEVs

• Even under optimistic assumptions

• CAFE emissions targets can be met by

• Technology penetration is driven only by

regarding ICE improvements and light-

utilizing ICE improvements and some

government targets for PHEVs and EVs

weight measures, all OEMs will need

weight reduction technology – OEMs

• Fuel consumption targets can be met by

xEVs to comply with 2020 CO

also have no cost incentive to apply xEV

optimizing ICE in all segments

emissions targets

technologies on a large scale

• Fleet emissions are possible, but there

PUSH • In terms of costs, hybrid light and

• However, the ZEV mandate and the

is no clear indication yet

PHEVs are most favorable

ability to earn credits will lead OEMs to

• If fleet emissions will be set, high xEV

build at least some PHEVs and EVs

penetration expected

• No TCO advantage for FHEV, PHEV or

• No TCO advantage for xEV powertrains • Almost no customer pull for xEVs –

due to low fuel costs

except in luxury segment

• Hybrid lights will become neutral as

• However, some customers are willing to • Light and full hybrids would offer

regards TCO, but will provide additional

pay for xEVs for environmental image

significant consumption advantages, but

TCO advantage is limited due to low

PULL • In larger-car segments, customers will

be willing to pay more for higher

• No willingness to pay for "green" image

performing hybrids

– in luxury segment, innovativeness of

• Only niche demand for BEVs

xEVs is an important purchase criteria

Source: Interviews; Roland Berger

To meet CO emission targets, OEMs will mostly introduce xEV only

according to the cost of CO emission reductions in their fleet

Assumption for xEV usage at OEMs to comply with EU CO emission regulation

Gap between CO fleet

Cost of cutting CO

emissions and CO targets

Usage of xEVs types to close the gap at OEMs1)

emissions2)

0 OEM will offer xEVs in segments to fulfill customer

requirement and skim willingness to pay – Hybrid light in large/luxury cars and minor share in medium size cars, PHEVs in large/luxury cars, BEVs in mini/small cars

1 Intensify usage of hybrid light in medium size and

small cars and PHEV usage in larger cars

2 Expand PHEV usage to medium size cars

3 Increase EV penetration in smaller cars and

expand usage to medium size cars

1) Based on interviews, validation with TCO calculations 2) Assessment is based on a calculation of xEV CO emission reduction potential, customer willingness to pay and cost (components and other cost)

Source: Interviews; Roland Berger

Hybrid light will become at least TCO neutral – Buyers of large/

luxury vehicles will be willing to pay for full hybrids and PHEVs

Pull factors for xEVs Europe, 2020

COMMENTS

• Assessment of TCO is

based on a detailed

calculation – taking into

account necessary uplift

CO emissions limits

of 200% on material

in company car fleets

cost for OEMs to

maintain EBIT margin

per vehicle

• Willingness to pay in

large and luxury segment

is driven by social pressure to be environ-mental compliant and

additional functions enabled by xEV power-trains (e.g. comfort start-

TCO neutral/advantage to best ICE-technology

Willingness to pay

Source: Interviews; Roland Berger

A significant share of powertrain electrification are stop-start and

micro-hybrid systems – but here, LiB are not competitive

Conventional starter batteries cannot be used effectively in start-stop and

micro-hybrid applications due to poor cycle life and poor charge acceptance

Initially, most of the start-stop systems used a 2 battery approach in order to fulfill

the requirements: 1 conventional starter battery (for starting only) plus 1 AGM

battery for power supply. Problems are cost for 2 batteries and limited life of the

AGM battery – Lithium Ion cell makers did expect a chance here

Recent developments in Lead-acid batteries (called Enhanced Flooded Battery )

have now be presented and are likely to become a viable and cost effective

solution for start-stop and micro-hybrid applications

Companies like JCI, Exide, Banner, Moll, Shin Kobe, GS-Yuasa and others will

probably be able to offer Lead-based products that will meet start-stop and

micro-hybrid requirements exceeding 200,000 km or 6 to 8 years of operation

at lower system costs than lithium-ion batteries.

B CELL ECONOMICS & TARGET PRICES

Price levels around 200 EUR/kwH (approx USD 250) in 2015 do not

provide sufficient EBIT to finance cost of capital

Typical 96 Wh PHEV cell – Cell cost structure 2015

Cell P&L breakdown, 2015

Cell material cost split, 2015

Total cost: approximately USD 22.1/cell ( 237 USD/kWh)

USD 13.4/cell

of total cell

Energy/Utilities 0%

Housing and feed-througs

Quality / Evironmental

1) Including carbon black content, foil and binder cost

Source: Roland Berger LiB Value Chain Cost model 2011

B CELL ECONOMICS & TARGET PRICES

Our calculation takes into account declining material prices–

Driven by strong competition to capture market shares

Impact on the cell manufacturing material prices (mid-term - 2015)

IMPACT FACTORS ON PRICES

Raw material

Standardization Competition/

Overall per kg

materials

capacities

impact 2015

SEPARATOR

ELECTROLYTE

Increasing the price

Decreasing the price

Overall strong price decrease

1) Investment, energy, labor 2) Process cost reduction potential for LFP available

Roland Berger "Battery material cost study V.2.4 / Q1 2011"

B CELL ECONOMICS & TARGET PRICES

Material manufacturer need to improve their materials to drive

down costs – resulting in additional R&D demand on cell level

Manufacturing cost calculation 2015 [USD/kg]

• According to latest analyst

reports the prices of Nickel,

Cobalt and Manganese will

decline through 2015

• Largely as a result thereof CAM

material costs will decrease by

between 7% and 22% between

• The costs of LFP will increase

largely as a function of higher

energy and utility costs which

account for 30% of total cost

• If high-capacity materials

(HCMA) is ready by 2015, this will offer a significant cost

advantage over other CAMs due

to higher energy density

compounded by lower material

Quality/Environment

Energy/Utilities

1) Total manufacturing costs 2) High quality differences 3) not available until >2015 4) not available until 2020

Source: Roland Berger LiB Value Chain Cost model 2011

B CELL ECONOMICS & TARGET PRICES

Declining cell prices will result in massive pressure on cell and CAM

manufacturer margins - not enough to finance costs of capital

Typical 96 Wh PHEV cell – Cell price breakdown 2015 [US $ / cell]

margin price

• For a typical CAM

– Raw materials account for

up to 55% of total cost

– D&A and utilities account

for up to 25% of total cost

• For a typical cell

– Raw materials account for

up to 58% of total cost

– D&A and utilities account

for up to 19% of total cost

Other Cathode CAM

material SG&A margin material D&A

• In view of their limited ability

Margin pressure

to offset sales price declines,

• Any price decrease beyond 24 USD / cell (lower than EUR 200 / kWh) will

CAM and cell manufacturers

have direct impact on CAM and cell manufacturer margins

will compete over a shrinking profit pool

1) Anode, separator, electrolyte, housing 2) Expected market price based on expert interviews

Source: Roland Berger LiB Value Chain Cost model 2011

B CELL ECONOMICS & TARGET PRICES

To significantly reduce cell costs beyond 2015, major innovations

in CAM technology and introduction of new CAMs are necessary

Typical 96 Wh PHEV cell – Impact of material improvements on cell prices (cost for Auto. customers)

HCMA cell

Cost reduction NCM cell 2015 – 2020

• Const. cell energy (at 96 Wh)

• In 2016 introduction of higher

density NCM CAM, resulting

in:specific cell energy increase

to141 Wh/kg and concurrent

reduction in NCM usage to 113 g

• In 2018 introduction of high-density

HCMA CAM: further increases specific cell energy to 144 Wh/kg with HCMA usage to 100 g

• HCMA price includes a license fee

• No changes in anode, separator

and electrolyte cost assumed in

add. potential 10.20$ /kWh

• Add. cell manufacturing process

Innovation pressure

improvement: potential ca. 10.15$

• Unless HCMA material is introduced, further price reduction potential of CAM materials is

limited and margins remain at unacceptable level

• Cell price forecast 2018.2020:

• Also cell manufacturer need (and will) improve processes and yield rate

200$ / kWh (incl. approx. 15%

margin for both CAM and cell

CAM cost share 1) Based on a high-density 50-50 mixture of NCM 111 and LiNiO

Source: Industry reports, experts interview, Roland Berger analysis

C IMPLICATIONS

The value chain is therefore expected to further consolidate (1/2)

TODAY (2012)

CHANGES BY 2020

Raw materials > Oligopoly

> Some selected new players

> New recycling companies

> Business models integrating recycling

> Dominated by Asian > New players (from specialty chemical

Cathodes,

sector ) especially for Automotive and

Separators,

> Partially specialized

precursors sourced > More integration of precursor

> Some cathode

Precursors

> Cathode manufacturing by cell

manufacturer only for top 2.3 with

cell manufacturer

large chemical business

Source: Roland Berger

C IMPLICATIONS

The value chain is expected to further consolidate (2/2)

TODAY (2012)

CHANGES BY 2020

Battery cells / > Some JVs

> Massive consolidation (cost

pressure, innovation)

("LiB manuf.") > Established players

> Auto-Cell manuf. JV's as exemption

research spin-offs with public & IPO funding leaving the market

> Mainly by OEMs (

JVs Increased outsourcing, but still

assembly

dominated by in-house assembly

> Selected supplier – > Some cell manufacturers try to deliver

larger part of system (incl. electronics)

> Limited LiB alone

Source: Roland Berger

Source: http://www.cluster-smab.de/de/component/phocadownload/category/14-energieumwelt.html?download=212:lithium-ion-batteries

VOIR LE SITE SENEGALIE : HEPATITES* FIEVRE JAUNE* PALUDISME TOURISTA * VACCIN RECOMMANDE L'article ci-dessous est fait pour vous informer, le respect des règles de bon sens vous permettra de passer un agréable séjour (les médicaments cités ne le sont qu'à titre informatif). POUR ENTRER AU SENEGAL IL VOUS FAUT UN PASSEPORT.

attività 2012-2013 SPECIALE SCUOLE Foresteria "Casa del Parco" Escursioni per le scuole GIORNATA DEI PARCHI ATTIVITà APPA Serate naturalistiche Programma settimanale in Val di Peio Programma settimanale in Val di Rabbi Calendario escursioni Mobilità dolce nel Parco - Servizi Bus Navetta Speciale estate in Val di Peio