Dspace.library.daffodilvarsity.edu.bd

Performance Evaluation of Different Brands

of Pantoprazole Tablets

Submitted by

Md. Rasel Mamun

ID NO: 101-29-157

Department of Pharmacy

Daffodil International University

Supervised by

Sharifa Sultana

Department of Pharmacy

Daffodil International University

Pharmacy Department

Faculty of Allied Health Science

Daffodil International University

This is to certify that the results of the investigation that are embodied in this project are

original and have not been submitted before in substance for any degree or diploma of

this university. The entire present work submitted as a project work for the partial

fulfillment of the degree of bachelor of pharmacy, is based on the result of author's (Md.

Rasel Mamun, ID NO: 101-29-157) own investigation.

Sharifa Sultana Lecturer Department of Pharmacy Faculty of Allied Health Science Daffodil International University

I would like to express my deep praise to the Almighty Allah who has given me the

ability to complete my project work and the opportunity to study in this subject.

I am very much grateful to my honorable project supervisor Sharifa Sultana , Lecturer,

Daffodil International University for her excellent guidance and constant supervision as

well as for providing necessary information regarding the project & also for her support

in completing the project

I would like to express my humble regards to Md. Arifur Rahman Fahim, Assistant

Professor & Head, Department of Pharmacy, Daffodil International University.

I also wish to offer my respect to all of the teachers of Pharmacy Department, Daffodil

International and thankful to other members for their excellent co-operation with us.

I am highly indebted to the Authority of Daffodil International University for their

guidance and constant supervision as well as for providing necessary information

regarding the project & also for their support in completing the project.

I am also grateful to my group members (Sumaiya Parvin, Jhumpa Raha, Nafisa

Yesmin) for their nice co-operation with me in completing my project.

I am also greatful to my friends especially Md. Riadh Hasan Rana, Md. Fahmid

Hasan, Mohammad Fariz Uddin, S.M Farid Imam, Sujan Sarker, Sakibur Rahman

for giving me mental support to complete my project work and paper.

Finally, I would like to express my gratitude towards my Parents & Other family

members for their kind co-operation and encouragement which help me in completion of

Dedicated to……

My Family Members

Abstract

Pantoprazole is a widely produced and marketed drug by many Pharmaceutical

companies in Bangladesh. This study is done to compare the evaluation parameter

(friability, weight variation, assay, disintegration and dissolution) of enteric coated

Pantoprazole tablets. Different brands of Pantoprazole tablets of top, middle and lower

listed company were collected from retail pharmacy of Bangladesh Market for their

evaluation test. Specified method of USP is followed for their evaluation test. RSD value

of weight variation of different drugs is in the range of (0.78-1.65)%, maximum friability

of the tablets of all brands is 0.4%, maximum disintegration time in phosphate buffer is

17.42 minutes, Maximum average potency among the brands is 98.14 % and minimum

potency is 94.60%, among the brands the maximum drug release in 0.1N HCl is 6.06 ,

minimum dissolution in phosphate buffer after 45 minutes is 79.94% and the maximum is

88.03%. The result of friability, weight variation, and assay and disintegration tests of all

marketed products comply with pharmacopoeial limit except some parameter in case of

lower listed company. This study is done to view the scenario of the quality of different

brands of Pantoprazole tablets in Bangladesh market.

Keywords: Enteric coated tablet, Pantoprazole, Proton pump inhibitors, Weight

variation, Disintegration, Dissolution.

Chapter one – Introduction

Definition of tablet

Classification of tablet

Properties of tablet

Advantage of tablet

Quality & criteria of drugs

Evaluation Parameter of tablets

Weight variation test

Disintegration test

Assay / Potency test

Factors / source of quality variation

History of Pantoprazole

Pharmacology of Pantoprazole

Some market preparation available in Bangladesh

Chapter Two- Materials & Methods

Materials

Collection of samples

Collection of standard

Coding of tablets

Labeling on the inner cartoon of the collected samples

Reagents used for the study

Instruments used for the study

Physical analysis

Weight variation test

Friability test of tablets

Disintegration test of tablets

Dissolution rate test of tablets

Chemical analysis

Preparation of standard curve of pantoprazole

Assay / Potency test

Chapter Three - Results and discussion

Result & discussion of weight variation test

Result & discussion of friability test

Result & discussion of disintegration test

Result & discussion of assay / potency test

Result & discussion of dissolution test

List of tables

Adverse drug reaction reported in clinical trial of adult patients 15

with GERD at a frequency of > 2%

Weight variation of P01

Weight variation of P02

Weight variation of P03

Weight variation of P04

Weight variation of P05

Friability of various brands of Pantoprazole

Disintegration of various brands of Pantoprazole

Dissolution rate of different brands of Pantoprazole tablets in

Dissolution rate of P01

Dissolution rate of P02

Dissolution rate of P03

Dissolution rate of P04

Dissolution rate of P05

List of figures

Figure No.

Structure of Pantoprazole

3 – D structure of Pantoprazole

Mechanism of acid inhibition

Analytical balance used for weight variation test

Friability test apparatus for friability test

Disintegration apparatus used for disintegration test

Dissolution apparatus used for dissolution test

Standard curve of Pantoprazole

UV spectroscopy used to measure absorbance

Friability of various brands Pantoprazole tablets

Disintegration time of various brands of Pantoprazole 47

Average potency of different market preparations of 50

Pantoprazole tablets

Dissolution rate of various brands of Pantoprazole 50

tablets in 0.1N HCl after 2 hrs.

Dissolution rate of various brands of Pantoprazole 52

tablets in phosphate buffer

Chapter One

"Daffodil International University"

1.1 An Overview

Bangladesh with a population of about 166 million is one of the developing countries of

South Asia and is actively involved in the Action Program of Essential Drugs proposed by

WHO. Through a developing country, over the last few years, Bangladesh has shown

commendable development in the pharmaceutical sector. About 300 pharmaceutical

companies are operating at the moment. Current market size is approximately 30,000 million

taka per year. Only 3% of the drugs are imported, the remaining 97% come from local

companies. Positive developments in the pharmaceutical sector have enabled Bangladesh to

export medicine to global markets. At present, Bangladesh's pharmaceutical industry is

effectively exporting their products to 79 countries. The number is expected to grow in the

coming months. In addition to regular products like tablets or capsules; HFA inhalers, nasal

sprays, IV infusions and other high-tech products are being exported from the country.

Bangladesh's pharmaceutical products in every way, meet international standard.

Actual growth of pharmaceutical industry in the country started in 1982, when the Drug

Control Ordinance was promulgated. The restriction of disproportionate import of drugs

encouraged local companies to increase production of their own products. Although this

displeased the multinational companies those were importing medicines to Bangladesh, the

regulation accelerated growth of local companies.

Pantoprazole is in a group of drugs called proton pump inhibitors. It decreases the amount of

acid produced in the stomach. Pantoprazole is used to treat erosive esophagitis (damage to the

esophagus from stomach acid), and other conditions involving excess stomach acid such as

Zollinger-Ellison syndrome. Pantoprazole is not for immediate relief of heartburn symptoms.

Pantoprazole may also be used for purposes not listed in this medication guide. Pantoprazole

is not for immediate relief of heartburn symptoms.

"Daffodil International University"

1.2 Tablet

Tablets are solid preparations each containing a single dose of one or more active ingredients

and obtained by compressing uniform volumes of particles. They are intended for oral

administration. Some are swallowed whole, some are after being chewed, some are dissolved

or dispersed in water before being administered and some are retained in the mouth where the

active ingredients liberated.

Tablets are usually circular solid cylinders, the end surfaces of which are flat or convex.

These are the most widely used solid dosage form medicaments because they offer a number

of advantages to the patient, prescriber, manufacturer to the patient, prescriber, manufacture

and the manufacturing pharmacist. Because of these advantages their popularity is

continuously increasing day by day.

1.2.1 Classification of Tablets

Mainly tablets are classified into two classes

A. Compressed tablets

B. Molded tablets

1.2.1.1 Compressed tablets

The compressed tablets usually prepared on large scale production methods, whereas the

molded tablets are prepared extemporaneously on small scale . This two main type of

tablet are further classified as follows :

1. Chewable tablets

2. Sublingual tablets

3. Effervescent tablets

4. Soluble tablets

5. Dispersible tablets

6. Gastro-resistant tablets

7. Modified release tablets

8. Tablets for use in the mouth

10. Soluble tablets

11. Layered tablets

"Daffodil International University"

1.2.1.2 Molded tablets

1. Hypodermic tablets

2. Dispensing tablets

1.2.2 Properties of a Good Tablet

Ø It should be accurate and uniform in weight.

Ø The size and shape should be reasonable for easy administration.

Ø The tablets should not be too hard to disintegrate in the stomach.

Ø There should not be any incompatibilities.

Ø They should be chemically and physically stable during storage.

Ø They should not break during transportation or crumble in the hands of the patient.

Ø They should be attractive in appearance.

Ø There should not be any manufacturing defects like cracking or chipping or

Ø They should be easy and economical in production.

Ø After administration, it should disintegrate readily.

1.2.3 Advantages

Ø Tablets have the following advantages

Ø They are easy to swallow

Ø They are easy to carry

Ø They are attractive in appearance

Ø Sugar coating can mask unpleasant taste

Ø They don't require any measurement of dose. The strip or blister packing has further

facilitated the process of taking the dose by the patient. Moreover it providing a sealed

covering which protects the tablets from atmospheric conditions likes as air, moisture and

Ø Some of the tablets are provided into halves and quarters by drawing lines during

manufacturing to facilitate breakage whenever a fractional dose is required.

Ø An accurate amount of medicament even if very small can be incorporated

Ø Tablets provide prolonged stability to medicament

Ø The incompatibilities of medicaments and their deterioration due to environmental

factors are less in tablet form.

"Daffodil International University"

Ø Since they are produced on a large scale therefore their cost of production is relatively

low, hence economical.

1.3 Quality and Its Criteria

Quality is an absolute necessity for medicines. The quality of drugs means quality of

treatment that ensures the well being of the patients. According to the WHO (World Health

Organization), the manufacturers must assume responsibility for the quality of the drugs he

produces. A medicinal product must satisfy certain pharmacopoeial standards to claim it to be

a quality drug. The principal criteria for a quality drug product are shown in figure-1.1

Regulatory

Aim of Quality

Compliance

Stability

Efficacy

Fig.1.1: The aim for Quality.

Ø Safety

Safety of medicine implies that the drug substance must meet certain safety requirements

relating to its intended use. No drug, particularly prescription drugs, can be called absolutely

safe. In the real life situation the drug-related risks (side effects) need to be compared with

the risk associated with the benefit to the patient to evaluate the risk-benefit ratio. It is this

ratio which one must use to judge the drug's therapeutic value. Apart from the serious side-

effect which is inherent in the drug itself, such as teratogenicity, a medicinal product can

become unsafe due to many other factors such as cross-contamination, contamination with

pathogenic organisms, very high or low potency, wrong labeling, inadequate packaging and

storage conditions. So a careful and rational evaluation should be needed.

"Daffodil International University"

Ø Potency

The product must contain adequate drug substance in its active form. Harmful degradation

products must be absent or below defined limits.

Ø Efficacy

The effectiveness of a drug indicates its biological activity in animals or in human. The active

substance should be adequately released from its dosage form.

Ø Stability

Pharmaceutical preparations may exhibit chemical or physical instability. This may result in:

(a) Reduced activity of the drug.

(b) Formation of toxic degradation products and

(c) The drug may become inelegant and thus unacceptable.

The drug substance itself and its dosage form must be sufficiently stable to retain its

minimum potency requirements satisfying the national or international pharmacopoeial

monograph. In most western countries now-a-days ±5%, beyond the labeled potency is

considered acceptable, unless the manufacturer has sound arguments for a greater variation.

The finished product must be marketed in suitable packs to ensure its stability for use up to

the expiry date when stored under specified condition.

Ø Acceptability

Acceptability refers to the consumer or market acceptability. This relates to the organoleptic

properties such as its taste, odor, color, mode of use and qualities which are not directly

noticeable to patients, e.g., too high a level of microbial contamination. A medicine should

have pharmaceutical elegance for market acceptability.

Ø Regulatory compliance

Each unit pack of the product must be clearly and correctly labeled. Moreover, the product

must fulfill the regulatory requirements. Various information in support of the product such

as potency claim, indications, side–effects, precautions, storage conditions, self-life,

manufacturing date, batch number, instructions for use etc. must comply with the drug

"Daffodil International University"

1.4 Evaluation of Tablets

Tablets are evaluated according to their physical and chemical characteristics. To monitor

tablet's quality, quantitative evaluations and assessments of chemical, physical and

bioavailability properties must be made.

1.4.1 Weight Variation

In the process of compressing a tablet, of course there are problems, one of them is the

weight variation. Usually, the range is still tolerable for large-sized tablets (diameter> 10

mm) was 3%, while for small tablet (diameter <7mm) is 5%. However, this specification

ranges vary depending on the respective industry and the active ingredient of the drug. If the

active ingredient is an extremely potent drug, in terms of the number of doses are very small

(microgram scale) has a large effect, then the range specifications for tablet weight variation

would be minimized.

Tablet weight variation in compressing process is not a trivial thing. Moreover, when

affecting the uniformity of dosage units.

v Tablet weight variation may be caused by:

Ø Distribution at Hoover caused the vibration. So, small granule pushed, large granules will

come out first, because there is a process of consolidation. Therefore, needs to be put a

uniform granule size. So, before the compressing process begins, better evaluation the

particle size distribution first.

Ø The flow of granules is not good / not free-flowing granules

Ø Particle distribution is not normal, because the specific gravity is different, so that the

Ø Keep the uniform of particle size distribution. Not too many fines and not too many

granules. Granules with a large particle diameter which causes the resultant tablet has a

variety of unsightly weight, while too fine granules which causes unsightly flow time.

Ø Lubricant or glidant less or not mixed evenly.

"Daffodil International University"

v How to overcome the weight variation of tablets:

Ø Evenly distribution of particle size

If too many fines, then need to do are create a number of more granular. This case is

commonly found on the direct compression process. This need not happen if are careful in

choosing excipient for direct compression. The problem is excipient for direct compression is

usually relatively more expensive.

If the active ingredient of the drug is stable to heat and humidity, then an easier way is to

produce by wet granulation. Through granulation, drying and sifting, which formed granules

can be more evenly. Critical points that need more attention is the moisture content and size

of mesh used at the time of sifting.

If the active ingredients of drugs are not stable to heat and humid, then try to dry granulation,

compaction with the compactor machine or slugging. Note the size of mesh used to sift.

Ø Proper use of lubricant & glidant

To solve tablet weight variation, excipient Aerosol or colloidal Silicon Dioxide can be added.

This excipient was added to the external phase. The amount used is usually 1-2% of the total

weight of the tablet. Mixing for 10-15 minutes.

Ø Specific gravity too different

This case often occurs in the manufacture of tablets that contain more than one type of

granules. Two or more active ingredients each made in separate granules (usually because of

incompatible), then at the time of compression into one, and coupled with the outer phase. Or

two granules remain separate, but when compression using two different hopper, then

compress into one tablet.

Ø Proper tooling

Proper tooling of the compression machine can solve the problem of weight variation. It

means uniform size of each punch and diameter of the compression machine and as well as

same speed in every time.

Ø Optimum machine speed

Optimum machine speed can control the weight variation of tablets because too much high or

too much slow speed can vary the weight of tablets of different station.

"Daffodil International University"

v Requirement:

Requirement is met if the weight variation of tablets is of no more than 10 tablets differs from

average weight by more than percentage given below-

Average weight of tablets

Percentage of difference

More than 324 mg

Ø Accepted tablet

Not more than two tablets are outside the percentage limit and no tablet differs by more

than two times the percentage limit according to the above table.

Ø Suspected tablet

Not more than six tablets are outside the percentage limit and no tablet differs by more

than two times the percentage limit according to the table.

Ø Rejected tablets:

One tablet differs by more than two times the percentage limit according to the table. More

than six tablets are outside the percentage limit. Tablet weight variation in compressing

process is not a trivial thing. Moreover, when affecting the uniformity of dosage units.

1.4.2 Tablet friability test

Tablet Friability Tests are constantly subjected to mechanical shocks & aberration during the

manufacturing, packing and transportation process. Such stress can lead to capping,

aberration or eve breakage of the tablets It is therefore important that the tablet is formulated

to withstand such stress. Tablet Friability In order to monitor the resistance of tablets to such

stress and to decide on their suitability for further processing such as coating, tablets are

routinely subjected to friability test.

Friability Test Minimum weight loss of the tablet should not be NMT 1%.

"Daffodil International University"

v Necessity of friability test

Ø Friability test is closely related to tablet hardness and is designed to evaluate the ability of

the tablet to withstand abrasion in packaging, handling and shipping.

Ø Hardness of the tablet can be understood.

Ø Physical stability of the tablet can be determined

1.4.3 Disintegration test

Disintegration test is widely used in the pharmaceutical industry for evaluation of

disintegration capability of formulations and quality control of different dosage forms.

Disintegration tests are performed as per the pharmacopoeial standards. Disintegration is a

measure of the quality of the oral dosage form like tablets and capsules. Each of the

pharmacopoeia like the USP, BP, IP etc each have their own set of standards and specify

disintegration tests of their own. USP, European pharmacopoeia and Japanese pharmacopoeia

have been harmonized by the International Conference on Harmonization (ICH) and are

interchangeable.

The disintegration test is performed to find out the time it takes for a solid oral dosage form

like a tablet or capsule to completely disintegrate. The time of disintegration is a measure of

the quality. This is because, for example, if the disintegration time is too high; it means that

the tablet is too highly compressed or the capsule shell gelatin is not of pharmacopoeial

quality or it may imply several other reasons. And also if the disintegration time is not

uniform in a set of samples being analyzed, it indicates batch inconsistency and lack of batch

v Disintegration Test Method

This test is provided to determine whether tablet disintegrate within the prescribed time when

placed in a liquid medium under the experimental conditions presented below. For the

purposes of this test disintegration does not imply complete dissolution of the unit or even of

its active constituent. Complete disintegration is defined as that state in which any residue of

the unit, except fragments of insoluble coating or capsule shell, remaining on the screen of

the test apparatus or adhering to the lower surface of the discs, if used, is a soft mass having

no palpably firm core.

"Daffodil International University"

v Apparatus

Ø Basket-rack assembly

The basket-rack assembly consists of six open-ended transparent tubes, each 75.0-80.0 mm

long and having an internal diameter of 20.70-23.00 mm and a wall 1.0-2.8 mm thick; the

tubes are held in a vertical position by two plates, each 88-92 mm in diameter and 5.00-8.50

mm in thickness, with six holes, each 22-26 mm in diameter, equidistant from the centre of

the plate and equally spaced from one another. Attached to the lower surface of the lower

plate is a woven stainless steel wire mesh, which has a plain square weave with 1.8-2.2 mm

apertures and with a wire diameter of 0.570-0.660 mm. The parts of the apparatus are

assembled and rigidly held by means of three bolts passing through the two plates. A suitable

means is provided to suspend the basket-rack assembly from the raising and lowering device

using a point on its axis. The design of the basket-rack assembly may be varied somewhat

provided the specifications for the glass tubes and the screen mesh size are maintained.

The use of discs is permitted only where specified or allowed. Each tube is provided with a

cylindrical disc 9.35-9.65 mm thick and 20.55-20.85 mm in diameter. The disc is made of a

suitable, transparent plastic material having a specific gravity of 1.18-1.20. Five parallel 1.9-

2.1 mm holes extend between the ends of the cylinder. One of the holes is centered on the

cylindrical axis. The other holes are centered 5.8-6.2 mm from the axis on imaginary lines

perpendicular to the axis and parallel to each other. Four identical trapezoidal-shaped planes

are cut into the wall of the cylinder, nearly perpendicular to the ends of the cylinder. The

trapezoidal shape is symmetrical; its parallel sides coincide with the ends of the cylinder and

are parallel to an imaginary line connecting the centers of two adjacent holes 6 mm from the

cylindrical axis. The parallel side of the trapezoid on the bottom of the cylinder has a length

of 1.5-1.7 mm and its bottom edges lie at a depth of 1.50-1.80 mm from the cylinder's

circumference. The parallel side of the trapezoid on the top of the cylinder has a length of

9.2-9.6 mm and its centre lies at a depth of 2.5-2.7 mm from the cylinder's circumference.

All surfaces of the disc are smooth. If the use of discs is specified, add a disc to each tube and

operate the apparatus as directed under procedure. The use of automatic detection employing

modified discs is permitted where the use of discs is specified or allowed. Such discs must

comply with the requirements of density and dimension given in this chapter.

"Daffodil International University"

v Procedure of disintegration for different tablets

The disintegration test for each dosage form is given in the pharmacopoeia. There are some

general tests for typical types of dosage forms. However, the disintegration test prescribed in

the individual monograph of a product is to be followed. If the monograph does not specify

any specific test, the general test for the specific dosage form may be employed. Some of the

types of dosage forms and their disintegration tests are:

Ø Uncoated tablets

Tested using distilled water as medium at 37+/-2 C at 29-32 cycles per minute; test is

completed after 15 minutes. It is acceptable when there is no palpable core at the end of the

cycle (for at least 5 tablets or capsules) and if the mass does not stick to the immersion disc.

Ø Coated tablets

The same test procedure is adapted but the time of operation is 30 minutes.

Ø Enteric coated/ Gastric resistant tablets

The test is carried out first in distilled water (at room temperature for 5 min.; USP and no

distilled water per BP and IP), then it is tested in 0.1 M HCL (up to 2 hours; BP) or

Stimulated gastric fluid (1 hour; USP) followed by Phosphate buffer, pH 6.8 (1 hour; BP) or

Stimulated intestinal fluid without enzymes (1 hour; USP).

Ø Chewable tablets

Exempted from disintegration test (BP and IP), 4 hours (USP). These are a few examples for

illustration. The disintegration tests for capsules, both hard and soft gelatin capsules are also

performed in a similar manner. Also, the USP also provides disintegration tests for

suppositories, peccaries etc.

v Factors affecting disintegration: several factors can significantly affect the

disintegration time of tablets:

Ø Disintegrants

A good disintegrant will quickly break up a tablet into primary particles and ensures that the

drug molecules are exposed for dissolution. Examples include corn and potato starches,

sodium starch glycolate, cellulose derivatives such as sodium carboxymethyl cellulose,

polyvinyl pyrolidone etc.

"Daffodil International University"

Ø Manufacturing process

The manufacturing processes have great influence on the disintegration behavior of tablets.

The total amount of disintegrants is added in two portions. The major part is incorporated to

the powders before granulation and the rest part is mixed with the dried granules along with

lubricants. Disintegrants added in this manner serves two purposes, those added after

granulation breaks the tablet apart into granules and the portion added before granulation

breaks the granules into fine particles.

Ø Binders and lubricants

The concentration of binder and lubricant used in the formulation has effect on disintegration

time. At lower concentration of lubricant and binder the disintegration time is lower than that

at higher concentration.

v Applications of Disintegration test:

Disintegration test is a simple test which helps in the pre-formulation stage to the formulator.

It helps in the optimization of manufacturing variables, such as compressional force and

dwell time. This test is also a simple in-process control tool to ensure uniformity from batch

to batch and among different tablets It is also an important test in the quality control of tablets

and hard gelatin capsules.

v Advantages of Disintegration tests:

1. This test is simple in concept and in practice.

2. It is very useful in pre-formulation, optimization and in quality control.

1.4.4 Dissolution Test

In the pharmaceutical industry, drug dissolution testing is routinely used to provide critical in

vitro drug release information for both quality control purposes, i.e., to assess batch-to-batch

consistency of solid oral dosage forms such as tablets, and drug development, i.e., to predict

in vivo drug release profiles. In vitro drug dissolution data generated from dissolution testing

experiments can be related to in vivo pharmacokinetic data by means of in vitro-in vivo

correlations (IVIVC). A well established predictive IVIVC model can be very helpful for

drug formulation design and post-approval manufacturing changes.

"Daffodil International University"

v Necessity of dissolution testing

Ø For selection of the formulation in the development phase:

▪ By comparison of the dissolution profiles of innovator product with those of

▪ This should be a basic strategy in R&D to maximize the chances of bioequivalence

Ø It is a requirement for comparative dissolution data for the bio-batch and innovator

batch, Same batches as used in bioequivalence study:

▪ Submit report with data, profile comparison & discussion

▪ This report forms part of pharmaceutical development report

Ø Demonstration of in vivo bioequivalence of one or more of the lower strength(s) of

an FPP may be waived based on:

▪ An acceptable in vivo BE study of the highest strength against the comparator product

▪ Demonstration of similarity of dissolution profiles,

▪ If the lower strength is proportionally similar in formula to the higher strength (bio-

▪ If all pharmacokinetic requirements are met

Ø Comparison of the release properties of pivotal batches:

▪ To demonstrate in vitro similarity of such batches.

▪ The studies should be submitted in dossier as part of the FPP development report.

Ø Selection of the dissolution specifications for product release & stability purposes:

▪ Conditions and acceptance criteria to be set

▪ The dissolution profiles of the bio-batch should be used for this purpose

▪ A dissolution specification should be able to detect inadequate release properties of the

commercial batches

Ø Post-approval amendment application

▪ Assessment of formulation changes to demonstrate that the profiles of the amendment

batch and the current batch are similar

"Daffodil International University"

v Apparatus

All parts of the apparatus, including any metal that may come into contact with the sample to

be tested or the dissolution medium, should be made from a chemically inert material and

should not adsorb, react or interfere with the preparation or the dissolution medium. The

dissolution assembly should be constructed in such a way that any vibration is reduced to a

minimum. Use an apparatus that allows full visibility of all operations.

Ø Paddle

The apparatus consists of a cylindrical vessel of suitable glass or other suitable transparent

material with a hemispherical bottom and a nominal capacity of 1000 ml. The vessel is

covered to prevent evaporation of the medium with a cover that has a central hole to

accommodate the shaft of the stirrer and other holes for the thermometer and for devices for

withdrawal of liquid. The stirrer consists of a vertical shaft with a blade at the lower end. The

blade is constructed around the shaft so that it is flush with the bottom of the shaft. When

placed inside the vessel, the shaft's axis is within 2mm of the axis of the vessel and the

bottom of the blade is 25 ± 2mm from the inner bottom of the vessel. The upper part of the

shaft is connected to a motor provided with a speed regulator so that smooth rotation of the

stirrer can be maintained without any significant wobble. The apparatus is placed in a water-

bath that maintains the dissolution medium in the vessel at 37 ± 0.5 °C.

Ø Basket

The apparatus consists of the same apparatus as described for "Paddle", except that the paddle

stirrer is replaced by a basket stirrer. The basket consists of two parts. The top part, with a

vent, is attached to the shaft. It is fitted with three spring clips, or other suitable attachments,

that allow removal of the lower part so that the preparation being examined can be placed in

the basket. These three spring clips firmly hold the lower part of the basket concentric with

the axis of the vessel during rotation. The lower detachable part of the basket is made of

welded-seam cloth, with a wire thickness of 0.254 mm diameter and with 0.381 mm square

openings, formed into a cylinder with a narrow rim of sheet metal around the top and the

bottom. If the basket is to be used with acidic media, it may be plated with a 2.5-µm layer of

gold. When placed inside the vessel, the distance between the inner bottom of the vessel and

the basket is 25 ± 2mm.

"Daffodil International University"

v Factors affecting dissolution- There are various factors that affect the dissolution

property of drugs like-

· Physicochemical factors of drug

These include the size and shape of the drug particles. From the Noyes and Whitney's

equation it is clear that-

Ø The surface area is directly related with the dissolution rate i.e., with the more surface

area (decreased particle size) the dissolution rate will also be increased.

Ø The solid phase characteristics of drugs, such as amorphicity, crystalline, states of

hydration and polymorphic structure have shown to have a significant influence on the

dissolution rate. For example, the amorphous form of novobiocin has a greater solubility

and higher dissolution rate than the crystalline form.

· Formulation factors

To satisfy certain pharmaceutical functions, various adjuncts such as diluents, binders,

disintegrants, granulating agents, lubricants, etc. are almost always used. They have very

significant effects on dissolution process e.g., usually hydrophilic lubricants like sodium

lauryl sulfate increases the dissolution rate of the drug than the hydrophobic that of

1.4.5 Assay / content uniformity test

Potency of tablet is expressed in term of grams, milligrams or micrograms (for some potent

drugs) of drugs per tablet and is given as the label strength of the product. Official compendia

or other standards provide an acceptable potency range around the label potency. For highly

potent, low dose drugs such as digitoxin, this range is usually not less than 90% and not more

than 110% of the labeled amount. For most other larger dose drugs in tablet form the official

potency range that is permitted is not less than 95% and not more than 105% of the labeled

amount. In general official potency analytical methods require that a composite sample of the

tablets be taken, ground up, mixed, and analyzed to produce an average potency value. In

composite assays, individual discrepancies can be masked by use of the blended sample.

"Daffodil International University"

v Importance of assay / content uniformity test

Ø Provide same dose to the patient.

Ø Provide optimum Plasma concentration of the drugs.

Ø Excellent output of the drug by recovering the disease.

1.5 Factors/ Source of Quality Variation

Because of the increasing complexity of modern pharmaceutical manufacture arising from a

variety of unique drugs and dosage forms, complex ethical, legal and economic

responsibilities have been placed on those concerned with manufacture of modern

pharmaceuticals. An awareness of these factors is the responsibility of all those involved in

the development, manufacture, control and marketing of quality products. A systematic

effective quality assurance program takes into consideration potential raw material, in-

process checking, packaging material, and labeling and finished product variables. The major

causes that lead to substandard drugs are given below:

(a) Addition of incorrect quantity of active ingredient or date expired sub-potent

(b) Non-uniform distribution of active ingredients and

(c) Poor stability of active ingredients in the finished product materials.

1.6 Information about the drug under analysis

1.6.1 History of Pantoprazole

Evidence emerged by the end of the 1970s that the newly discovered proton pump (H+,K+-

ATPase) in the secretory membrane of the parietal cell was the final step in acid secretion.

Literature from anaesthetic screenings led attention to the potential antiviral compound

pyridylthioacetamide which after further examination pointed the focus on an anti-secretory

compound with unknown mechanisms of action called timoprazole. Timoprazole is a

pyridylmethylsulfinyl benzimidazole and appealed due to its simple chemical structure and

its surprisingly high level of anti-secretory activity.

Optimization of substituted benzimidazoles and their antisecretory effects were studied on the

newly discovered proton pump to obtain higher pKa values of the pyridine, thereby

facilitating accumulation within the parietal cell and increasing the rate of acid-mediated

conversion to the active mediate. As a result of such optimization the first proton pump

"Daffodil International University"

inhibiting drug was released on the market, Omeprazole. Pantoprazole would follow in its

footsteps, claiming their share of a flourishing market, after their own course of development.

Pantoprazole developed by Byk Gulden (Altana subsequently purchased Byk Gulden), is

marketed around the world by a number of companies including Altana (now Nycomed),

Wyeth, and Sanofi-Aventis. Drug in Focus this month will analyse the patent landscape

surrounding Pantoprazole based on information contained in GenericsWeb's Pipeline Selector

report, with a view to launching generic equivalents.

1.6.2 Chemistry

Pantoprazole is in a group of drugs called proton pump inhibitors. Pantoprazole sodium is a

pyridinyl)methyl] sulfinyl]1H-benzimidazole sesquihydrate, a compound that inhibits gastric

acid secretion. Its empirical formula is C16H14F2N3NaO4S x 1.5 H2O, with a molecular weight

of 432.4. The structural formula is:

Figure1.2: Structure of Pantoprazole

"Daffodil International University"

Figure: 1.3-dimensional structure of Pantoprazole

Pantoprazole sodium sesquihydrate is a white to off-white crystalline powder and is racemic.

Pantoprazole has weakly basic and acidic properties. Pantoprazole sodium sesquihydrate is

freely soluble in water, very slightly soluble in phosphate buffer at pH 7.4, and practically

insoluble in n-hexane.

The stability of the compound in aqueous solution is pH-dependent. The rate of degradation

increases with decreasing pH. At ambient temperature, the degradation half-life is

approximately 2.8 hours at pH 5 and approximately 220 hours at pH 7.8.

1.6.3 Pharmacology

Pantoprazole is a widely used antiulcerent drug. Generally inactive at acidic pH of stomach,

thus it is usually given with a pro kinetic drug. It decreases the amount of acid produced in

the stomach by inhibiting H+K+ATPase (proton pumps). As it binds irreversibly to the

pumps, new pumps have to be made before acid production can be resumed. The drug's

plasma half-life is about 2 hours. Pantoprazole is used to treat erosive esophagitis (damage to

the esophagus from stomach acid), and other conditions involving excess stomach acid such

as Zollinger-Ellison syndrome. Pantoprazole is not for immediate relief of heartburn

"Daffodil International University"

1.6.3.1 Pharmacodynamic

v Mechanism of action of Pantoprazole

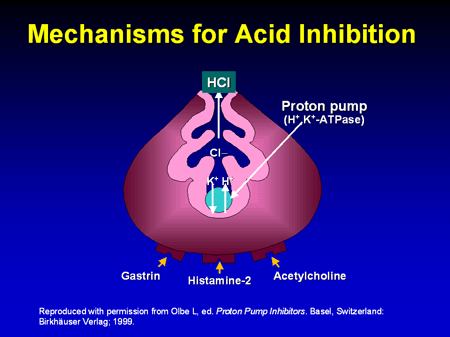

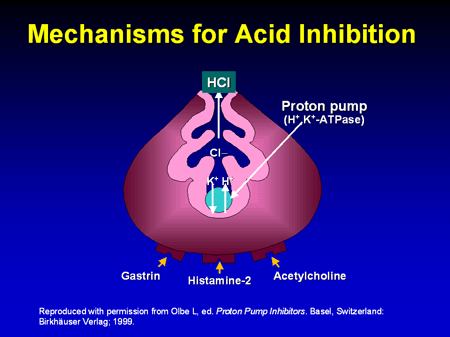

Figure1.4: Mechanism for acid inhibition

• Pumps protons out of the parietal cell and potassium ions back in

• Requires energy - provided by hydrolysis of ATP to ADP, catalysed by ATPase

• The proton pump is also called H+/K+-ATPase

• Chloride ions depart through a separate ion channel

• HCl is formed in the canaliculus

• The potassium ions exit the parietal cell as countering for the chloride ions and are

then pumped back in

• A separate potassium ion channel is used for K+ ions leaving the cell

Pantoprazole is a proton pump inhibitor (PPI) that suppresses the final step in gastric acid

production by covalently binding to the (H+, K+)-ATPase enzyme system at the secretory

surface of the gastric parietal cell. This effect leads to inhibition of both basal and stimulated

gastric acid secretion, irrespective of the stimulus. The binding to the (H+, K+)-ATPase

results in a duration of antisecretory effect that persists longer than 24 hours for all doses

tested (20 mg to 120 mg).

"Daffodil International University"

v Dosage form

Pantoprazole is available in IV form and oral (tablet, suspension) form.

v Indication

Pantoprazole is indicated where suppression of acid secretion is of therapeutic benefit.

Pantoprazole is registered for the following indications: -

Ø Peptic ulcer diseases (PUD)

Ø Gastro esophageal reflux diseases (GERD)

Ø Treatment of ulcer resistant to H2 receptor antagonists (H2RAs)

Ø Treatment of ulcers induced by non-steroidal anti-inflammatory drugs (NSAIDs)

Ø Gastrointestinal (GI) bleeding from stress or acid peptic diseases

Ø Eradication of Helicobacter pylori (in combination with antibiotics)

Ø Zollinger-Ellison syndrome

Ø Prophylaxis for acid aspiration syndrome during induction of anaesthesia

v Dosage and administration

Ø Usual Adult Dose for Erosive Esophagitis

• Treatment of Erosive Esophagitis: 40 mg orally once a day for up to 8 weeks; however

an additional 8 weeks may be considered for patients who have not healed after the

initial treatment. Safety and efficacy beyond 16 weeks of therapy have not been

• Maintenance of Healing of Erosive Esophagitis: 40 mg orally once a day. Controlled

studies have been limited to 12 months of Pantoprazole therapy.

"Daffodil International University"

Ø Usual Adult Dose for Gastroesophageal Reflux Disease

• Parenteral: 40 mg once a day for 7 to 10 days, administered via intravenous infusion

over a period of 15 minutes. Intravenous therapy should be discontinued as soon as the

patient is able to resume oral therapy.

• Oral: 40 mg orally once a day, for short-term administration (up to 8 weeks); however an

additional 8 weeks may be considered for patients who have not healed after the initial

treatment. Safety and efficacy beyond 16 weeks of therapy have not been established.

Ø Usual Adult Dose for Duodenal Ulcer

Orally once a day, dose was increased every 12 weeks by 40 mg increments to a

maximum of 120 mg per day, for 28 weeks. Data have revealed that monotherapy with

daily doses of 40 mg have been associated with complete duodenal ulcer healing in up to

87% and 94% of patients after 4 weeks and 8 weeks respectively.

Ø Usual Adult Dose for Gastric Ulcer

40 mg orally once a day. Data have revealed that monotherapy with daily doses of 40 mg

have been associated with complete gastric ulcer healing in up to 87% and 97% of

patients after 4 weeks and 8 weeks respectively.

Ø Usual Adult Dose for Stress Ulcer Prophylaxis

• Stress Ulcer bleeding prophylaxis in the Critical Care Setting: 80 mg twice daily, as a

bolus infusion over a period of 15 minutes, to a maximum daily dose of 240 mg, divided

into three equal doses.

• Peptic Ulcer rebleeding prophylaxis after homeostasis in the Critical Care Setting:

80 mg IV bolus, followed by continuous infusion of 8 mg/hr for 3 days, after which

therapy may be continued with an oral PPI.

"Daffodil International University"

Ø Usual Adult Dose for Peptic Ulcer

• Stress Ulcer bleeding prophylaxis in the Critical Care Setting: 80 mg twice daily,

as a bolus infusion over a period of 15 minutes, to a maximum daily dose of 240 mg,

divided into three equal doses.

• Peptic Ulcer rebleeding prophylaxis after homeostasis in the Critical Care

Setting: 80 mg IV bolus, followed by continuous infusion of 8 mg/hr for 3 days, after

which therapy may be continued with an oral PPI.

v Side Effects

Along with its needed effects, pantoprazole may cause some unwanted effects. Although

not all of these side effects may occur, if they do occur they may need medical attention.

Ø Abdominal or stomach pain

Ø blurred vision

Ø flushed, dry skin

Ø fruit-like breath odor

Ø increased hunger

Ø increased thirst

Ø increased urination

Ø troubled breathing

Ø unexplained weight loss

v Adverse Drug Reaction

Ø Clinical Trial Experience (Adults)

Safety in nine randomized comparative US clinical trials in patients with GERD included

1,473 patients on oral Pantoprazole 20 mg or 40 mg, 299 patients on an H2-receptor

antagonist, 46 patients on another proton pump inhibitor, and 82 patients on placebo. The

most frequently occurring adverse reactions are listed in Table 1.2

"Daffodil International University"

Table 1.1: Adverse Reactions Reported in Clinical Trials of Adult Patients with GERD

at a Frequency of > 2%

Comparators

(n=1473) %

(n=345) %

Additional adverse reactions that were reported for pantoprazole in clinical trials with a

frequency of ≤ 2% are listed below by body system:

Body as a Whole: allergic reaction, pyrexia, photosensitivity reaction, facial edema

Gastrointestinal: constipation, dry mouth, hepatitis

Hematologic: leukopenia, thrombocytopenia

Metabolic/Nutritional: elevated CK (creatine kinase), generalized edema, elevated

triglycerides, and liver enzymes elevated

Musculoskeletal: myalgia Nervous: depression, vertigo

Skin and Appendages: urticaria, rash, pruritus

Special Senses: blurred vision

Ø Post marketing Experience

The following adverse reactions have been identified during post approval use of

Pantoprazole. Because these reactions are reported voluntarily from a population of uncertain

size, it is not always possible to reliably estimate their frequency or establish a causal

relationship to drug exposure.

These adverse reactions are listed below by body system:

General Disorders and Administration Conditions: asthenia, fatigue, malaise.

Hematologic: Pancytopenia, agranulocytosis.

Hepatobiliary Disorders: Hepatocellular damage leading to jaundice and hepatic failure.

Immune System Disorders: Anaphylaxis (including anaphylactic shock)

Infections and Infestations: Clostridium difficile associated diarrhea.

Investigations: Weight changes

"Daffodil International University"

Metabolism and Nutritional Disorders: Hyponatremia, hypomagnesemia.

Musculoskeletal Disorders: Rhabdomyolysis, bone fracture.

Nervous: Ageusia, ysgeusia.

Psychiatric Disorders: hallucination, confusion, insomnia, somnolence.

Renal and Urinary Disorders: Interstitial nephritis

Skin and Subcutaneous Tissue Disorders: Severe dermatologic reactions (some fatal),

including erythema multiforme, Stevens-Johnson syndrome, and toxic epidermal necrolysis

(TEN, some fatal), and angioedema (Quincke's edema).

Ø Prolonged (>1 year), high-dose therapy

• Decreased gastric acidity increases serum chromogranin A (CgA) levels and may cause

false-positive diagnostic results for neuroendocrine tumors; temporarily discontinue PPIs

before assessing CgA levels.

• PPIs may decrease the efficacy of clopidogrel by reducing the formation of the active

• Gastric atrophy reported with long-term use of another PPI.

• Therapy increases risk of Salmonella, Campylobacter, and other infections.

• Hypomagnesaemia may occur with prolonged use (>1 year); adverse effects may result,

including tetany, arrhythmias, and seizures; in 25% of cases reviewed, magnesium

supplementation alone did not improve low serum magnesium levels, and the PPI had to

be discontinued.

• Infusion related reactions including thrombophlebitis and hypersensitivity reported.

• Prolonged treatment may lead to vitamin B12 malabsorption.

• Relief of symptoms does not eliminate the possibility of a gastric malignancy.

• Relief of symptoms does not preclude the presence of a gastric malignancy. Risk of

salmonella and campylobacter infections increased with use of proton pump inhibitors.

v Special warnings and precautions for use

Ø Pantoprazole for Delayed-Release Oral Suspension and Pantoprazole for Delayed-Release

Tablets should not be split, crushed, or chewed.

Ø Pantoprazole oral suspension packet is a fixed dose and cannot be divided to make a

"Daffodil International University"

Ø Pantoprazole Delayed-Release Tablets should be swallowed whole, with or without food

Ø Concomitant administration of antacids does not affect the absorption of Pantoprazole

Delayed-Release Tablets.

Ø Pantoprazole for Delayed-Release Oral Suspension should be administered approximately

30 minutes before a meal.

Ø Pantoprazole for Delayed-Release Oral Suspension should only be administered in apple

juice or applesauce, not in water, other liquids, or foods.

Ø Immediately report and seek care for any cardiovascular or neurological symptoms

including palpitation, dizziness, seizures, and tetany as these may be signs of

hypomagnesaemia.

Ø Immediately report and seek care for diarrhea that does not improve. This may be

a sign of Clostridium difficile associated diarrhea.

v Contra-indications

Pantoprazole is contraindicated in patients with known hypersensitivity to any component of

the formulation.

v Drug Interactions

Ø Interference With Antiretroviral Therapy

Concomitant use of atazanavir or nelfinavir with proton pump inhibitors is not

recommended. Coadministration of atazanavir or nelfinavir with proton pump inhibitors is

expected to substantially decrease atazanavir or nelfinavir plasma concentrations and may

result in a loss of therapeutic effect and development of drug resistance.

Ø Coumarin Anticoagulants

There have been postmarketing reports of increased INR and prothrombin time in patients

receiving proton pump inhibitors, including Panyoprazole, and warfarin concomitantly.

Increases in INR and prothrombin time may lead to abnormal bleeding and even death.

Patients treated with proton pump inhibitors and warfarin concomitantly should be

monitored for increases in INR and prothrombin time.

"Daffodil International University"

Ø Clopidogrel

Concomitant administration of pantoprazole and clopidogrel in healthy subjects had no

clinically important effect on exposure to the active metabolite of clopidogrel or

clopidogrelinduced plateletinhibition. No dose adjustment of clopidogrel is necessary when

administered with an approved dose of Pantoprazole.

Ø Drugs For Which Gastric pH Can Affect Bioavailability

Pantoprazole causes long-lasting inhibition of gastric acid secretion. Therefore, pantoprazole

may interfere with absorption of drugs where gastric pH is an important determinant of their

bioavailability (e.g., ketoconazole, ampicillin esters, and iron salts).

Ø Methotrexate

Case reports, published population pharmacokinetic studies, and retrospective analyses

suggest that concomitant administration of PPIs and methotrexate (primarily at high dose)

may elevate and prolong serum levels of methotrexate and/or its metabolite

hydroxymethotrexate. However, no formal drug interaction studies of Methotrexate with

PPIs have been conducted.

v Pregnancy and lactation

Ø Pantoprazole Pregnancy Warnings

Pantoprazole has been assigned to pregnancy category B by the FDA. Animal data have

failed to reveal evidence of fetal harm after rats or rabbits were given doses 88 and 40 times

the recommended human dose (based on body surface area), respectively. There are no data

from controlled human studies. Pantoprazole should only be used during pregnancy when

need has been clearly established.

Ø Pantoprazole Breastfeeding Warnings

Pantoprazole and its metabolites are excreted in the milk of rats. Pantoprazole has been

detected in human milk in a study of a single nursing mother following a single 40 mg oral

dose. Since many drugs are excreted in human milk, the manufacturer recommends that due

to the potential for serious adverse reactions in nursing infants, a decision should be made to

discontinue nursing or discontinue the drug, taking into account the importance of the drug

"Daffodil International University"

v Storage conditions

Store Pantoprazole for Delayed-Release Oral Suspension and Pantoprazole Delayed-Release

Tablets at 20° to 25°C (68° to 77°F); excursions permitted to 15° to 30°C (59° to 86°F).

v Shelf life

Shelf life of pantoprazole is 3 years but after first opening of the bottle use the medicinal

product within three months.

1.6.3.2 Pharmacokinetic

Pantoprazole Delayed-Release Tablets are prepared as enteric-coated tablets so that

absorption of pantoprazole begins only after the tablet leaves the stomach. Peak serum

concentration (Cmax) and area under the serum concentration time curve (AUC) increase in a

manner proportional to oral and intravenous doses from 10 mg to 80 mg. Pantoprazole does

not accumulate, and its pharmacokinetics are unaltered with multiple daily dosing. Following

oral or intravenous administration, the serum concentration of pantoprazole declines

biexponentially, with a terminal elimination half-life of approximately one hour.

In extensive metabolizers with normal liver function receiving an oral dose of the enteric

coated 40 mg pantoprazole tablet, the peak concentration (Cmax) is 2.5 µg/mL; the time to

reach the peak concentration (tmax) is 2.5 h, and the mean total area under the plasma

concentration versus time curve (AUC) is 4.8 µg•h/mL (range 1.4 to 13.3 µgh/mL).

Following intravenous administration of Pantoprazole to extensive metabolizers, its total

clearance is 7.6-14.0 L/h, and its apparent volume of distribution is 11.0-23.6 L.

A single oral dose of Pantoprazole for Delayed-Release Oral Suspension, 40 mg, was shown

to be bioequivalent when administered to healthy subjects (N = 22) as granules sprinkled over

a teaspoonful of applesauce, as granules mixed with apple juice, or mixed with apple juice

followed by administration through a nasogastric tube.

v Absorption

After administration of a single or multiple oral 40 mg doses of Pantoprazole Delayed-

Release Tablets, the peak plasma concentration of pantoprazole was achieved in

approximately 2.5 hours, and Cmax was 2.5 µg/mL. Pantoprazole undergoes little first-pass

metabolism, resulting in an absolute bioavailability of approximately 77%. Pantoprazole

absorption is not affected by concomitant administration of antacids.

"Daffodil International University"

Administration of Pantoprazole Delayed-Release Tablets with food may delay its absorption

up to 2 hours or longer; however, the Cmax and the extent of pantoprazole absorption (AUC)

are not altered. Thus, Pantoprazole Delayed-Release Tablets may be taken without regard to

timing of meals.

Administration of Pantoprazole granules 40 mg with a high-fat meal delayed median time to

peak plasma concentration by 2 hours. With a concomitant high-fat meal the Cmax and AUC

of Pantoprazole granules 40 mg sprinkled on applesauce decreased by 51% and 29%

respectively. Thus, Pantoprazole for Delayed-Release Oral Suspension should be taken

approximately 30 minutes before a meal.

v Distribution

The apparent volume of distribution of Pantoprazole is approximately 11.0-23.6 L

distributing mainly in extracellular fluid. The serum protein binding of pantoprazole is about

98% primarily to albumin.

v Metabolism

Pantoprazole is extensively metabolized in the liver through the cytochrome P450 (CYP)

system. Pantoprazole metabolism is independent of the route of administration (intravenous

or oral). The main metabolic pathway is demethylation by CYP2C19 with subsequent

sulfation. Other metabolic pathways include oxidation by CYP3A4. There is no evidence that

any of the pantoprazole metabolites have significant pharmacologic activity.

v Elimination

After a single oral or intravenous dose of 14C-labeled pantoprazole to healthy, normal

metabolizer volunteers approximately 71% of the dose was excreted in the urine, with 18%

excreted in the feces through biliary excretion. There was no renal excretion of unchanged

"Daffodil International University"

1.6.4 Some market preparation available in Bangladesh

Name of the company

Brand name

Dosage form available

Inj: 40 mg / ampoule

Inj: 40 mg / ampoule

Inj: 40 mg / ampoule

Inj: 40 mg / ampoule

"Daffodil International University"

Chapter Two

Materials & Methods

"Daffodil International University"

2.1 Materials

2.1.1. Collection of Sample

There are many brands of Pantoprazole tablets in Bangladesh. Samples were collected from

retail medicine shop of different areas of Dhaka city. The samples were properly checked for

their physical appearance, name of the manufacturer, batch number, manufacturing data,

expiry date, manufacturing license number, D.A.R. number and maximum retail price at the

time of purchase. No samples were bought and analyzed whom date of expiry had already

been passed. Collected samples also covered small, medium and big companies. The samples

were then coded with ethics for analysis.

2.1.2 Collection of standard

The U.S.P reference standard of Pantoprazole was obtained from Incepta Pharmaceutical Ltd.

The purity of the reference standard was 99.9%.

2.1.3 Coding of Tablet

Pantoprazole tablet from 5 different pharmaceutical companies were coded as

2.1.4 Labeling on the Inner Carton of the collected samples

Each of the containers of tablets and injection labeled with the following particulars:

(a) Brand name of the product

(b) Name of the manufacturer

(c) Composition of the product

(d) Batch number

(e) Manufacturing date

(g) Manufacturing license number

(h) D.A.R. number

(i) Maximum retail price (M.R.P.)

"Daffodil International University"

2.1.5 Reagents

Ø Distilled water

Ø Standard Pantoprazole

Ø Sodium hydroxide

Ø Phosphate buffer:

(a) 0.2 M Potassium Dihydrogen Phosphate

(b) 0.1 N Sodium Hydroxide

(c) Phosphoric acid

2.1.6 Instruments

Table No.2.1: Instruments used in this study

Instruments

Electronic balance

Ohaus CP213, China

Friability test apparatus

Disintegration test apparatus

Dissolution test apparatus USP Minhua,China

UV Visible Spectrophotometer PG instrumentation,England

2.2 Methods

2.2.1 Physical Analysis

2.2.1.1 Weight Variation test

The weight variation is routinely measured to help ensured that a tablet contains proper

"Daffodil International University"

Ø Procedure

10 tablets were taken and weighed individually by an analytical balance. The average weight

of the tablets was calculated. Then % of weight variation is calculated by using the following

Individual weight – average weight

% of weight variation = ´ ´ 100

In this way the weight variation for 5 different brands of Pantoprazole tablets were measured

and the observed value for each sample was recorded.

Figure 2.1: Analytical balance used for weight variation test

2.2.1.2 Friability test of tablets

Tablets friability results in weight loss of tablets in the package container, owing to partial

powdering, chipping or fragmentation of the tablets on attrition or wear. Tablets that are

chipped or mechanically eroded and no longer have sharp edges are of reduced

pharmaceutical elegance and reduced quality. Tablet friability often reflects lack of

cohesiveness on compression of the dry granulation from which the tablets are made.

Ø Procedure

5 tablets were taken and weighed by an analytical balance. Then the tablets were put in

Friabilator and the machine is allowed rotate at 30 R.P.M for 4 minutes .The tablets were

weighed again. Then the % of friability was calculated by the following formula:

Initial weight – final weight

% of friability = ´ 100

"Daffodil International University"

In this way % of friability was determined for 5 different brands of tablets and the observed

result for each sample was recorded.

Figure 2.2: Friability test apparatus used for friability test

2.2.1.3 Disintegration time test of tablets

Disintegration time is the length of time required for causing disintegration of tablet. This test

is important to evaluate a tablet since it directly influences the onset of action. This test not

only evaluates the quality but also the bioavailability and effectiveness of tablets.

Ø Procedure:

As Pantoprazole is an enteric coated tablet so at first the disintegrity was observed in 0.1N

HCl for 2 hours then check the disintegration time in phosphate buffer. About 700ml

Phosphate buffer was taken in 1000ml beaker and the beaker was placed into the device. One

Pantoprazole tablet was placed in each tube of basket rack & plastic disk is placed over each

tablet & the basket rack is accurately positioned into the beaker. The temperature was

maintained as 37±5

. A motor driven device helps to move the basket up down through a

distance of 5-6cm at a rate of 28-32 cycles per minutes.The time at which all the

Pantoprazole tablets passed through the sieve was the disintegration time & the average

disintegration time were calculated. In this way disintegration time was determined for 5

different brands of Pantoprazole tablets and the observed result for each sample was

"Daffodil International University"

Figure 2.3: Disintegration apparatus used for DT test

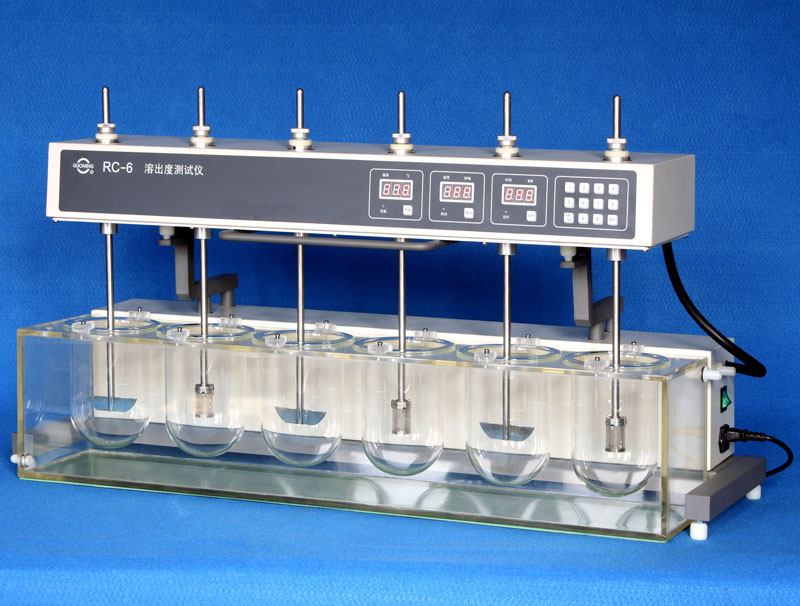

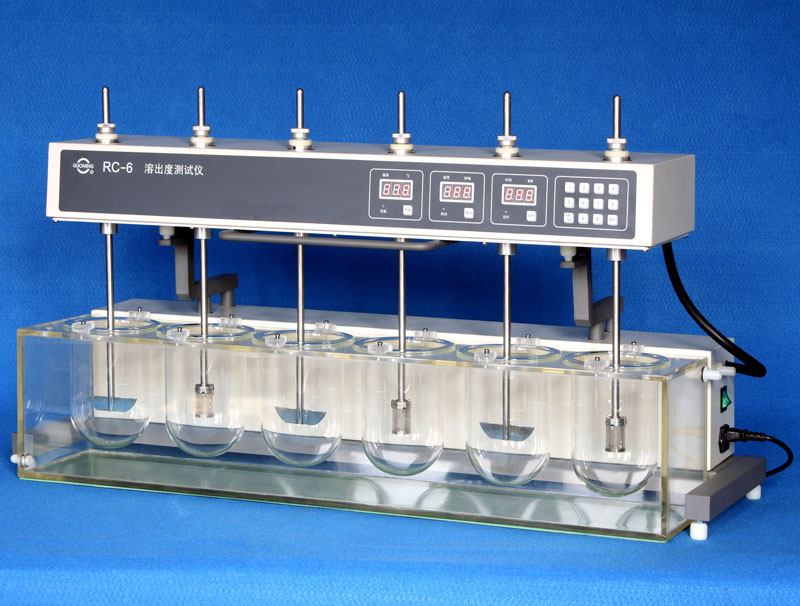

2.2.1.4 Dissolution rate test of tablets

Dissolution is the property or tendency of a drug to undergo solution, which affects the rate

of drug absorption.

Ø Medium: Phosphate Buffer pH 6.8

Ø Procedure

900 ml of 0.1N HCl solution was filled into 1000ml beaker of dissolution apparatus. Each

Pantoprazole tablets of each brand were placed into each beaker. The test was repeated for 3

times for 3 samples of each brand. The dissolution medium was heated up to 37±o.5 by an

auto heater & 100 R.P.M was adjusted. 5 ml solution was withdrawn from beaker after 2

hours and fill with 5 ml distill water. Then withdrawn solution was filtered through filter

paper. The withdrawn solution of the sample absorbance was measured at 289 nm by using

UV-visible spectrophotometer. Finally the percent release of Pantoprazole tablet was

determined. As Pantoprazole tablets were enteric coated it would not release not more than

10% after 2 hrs treatment with gastric HCl. Its dissolution medium is phosphate buffer. So

after that phosphate buffer of 6.8 pH was prepared and filled the beaker with pouring 900 ml

buffer in each beaker. The treated Pantoprazole tablets with 0.1N HCL for two hours in

dissolution apparatus was placed in the phosphate buffer dissolution medium. 5 ml sample

was withdrawn in every 10 minutes interval for 4 times and filled the beaker by adding 5

ml of distill water. Then the sample was filtered and by performing 10 times dilution

absorbance was measured at 289 nm.

"Daffodil International University"

In this way the dissolution rates of 5 different brands of Pantoprazole tablets were

determined and the observed value for each sample was recorded.

Figure 2.4: dissolution apparatus used for dissolution test

2.2.2 Chemical Analysis

2.2.2.1 Preparation of standard curve of Pantoprazole

10 mg of Pantoprazole was measured by the electronic balance and placed in 100ml

volumetric flask and dissolved by ethanol. Then the concentration of solution was attained

100µg/ml by adding Phosphate buffer. Then A series of standard solution of standard

pantoprazole eg, 2µg/ml, 4µg/ml, 6µg/ml, 8µg/ml, 10µg/ml, 12µg/ml, 14µg/ml, 16µg/ml,

were taken for check Absorbance at 242 nm against a blank for each solution by UV-

spectrophotometer. The measured absorbances were plotted against the respective

concentration of the standard solutions which give a straight line.

"Daffodil International University"

Table 2.2: Absorbance of different concentration of standard Pantoprazole solution

measured at 271 nm

Concentration (mcg /ml)

Absorbance

Average absorbance

"Daffodil International University"

Figure: 2.5 Standard curve of Pantoprazole

Figure 2.6: UV spectroscopy used for measuring the absorbance

"Daffodil International University"

2.2.2 Assay / potency test

2.2.2.1 Preparation of standard solution

Ø Preparation of standard solution of Pantoprazole:

To prepare a standard solution,10 mg of Pantoprazole was measured by the electronic balance

and placed in 100 ml volumetric flask and dissolver by ethanol. Then the concentration of

solution was attained 100µg/ml by adding Phosphate buffer. Then 1 ml solution was taken

and diluted to 10 ml and the concentration goes to 10 mcg /ml.

Ø Preparation of assay solution

20 tablets of of each brands of Pantoprazole were weighed and powdered. Equivalent weight

of 10 mg of Pantoprazole sodium was weighed as sample and dissolved in 100 ml ethanol

then the solution was filtered. 1 ml of sample was taken and made the volume 10 ml.

Absorbance was measured at 289 nm using UV Spectrophotometer.

Ø Measurement

The absorbance of both standard and sample were measured at 289 nm using UV

Spectrophotometer.

Ø Calculation

Finally the assay was calculated by using the following equation.

Assay of sample = ´ DF ´ P ´ Wt Avg

Abs of Std ´ Wt of Sam

Where, Abs of Sam = Absorbance of sample

Wt of Std = Weight of standard

Abs of Std = Absorbance of standard

Wt of Sam = Weight of sample

DF = Dilution factor

P = Potency of standard

Wt Avg = Average weight of sample

"Daffodil International University"

Chapter Three

Results & Discussion

"Daffodil International University"

3.1 Weight Variation

The weight variations of five brands Pantoprazole were determined & the observed results

are shown in the following table. The USP specification of weight variation: ±7.5 for 130 to

324mg average weight of tablet & ± 5% for more than 324mg of average weight of tablet. It

was observed that all of the brands meet the USP specification.

Table 3.1: Weight Variation of P01

SI

Individual

No weight(mg)

Weight(mg)

variation %

Table 3.2 : Weight variation of P02

Individual

RSD% Comment

No weight(mg)

Weight(mg)

variation %

"Daffodil International University"

Table 3.3: Weight variation of P03

Individual

No weight(mg)

Weight(mg)

variation %

Table 3.4: Weight Variation of P04

Individual

No weight(mg)

Weight(mg)

variation %

Table 3.5: Weight variation of P05

Individual

No weight(mg)

Weight(mg)

variation %

"Daffodil International University"

3.2 Friability

The friability of 5 different brands of Pantoprazole tablets were measured according to the

procedure and the observed results are shown in the table 3.2

Table 3.2: Friability of various brands of pantoprazole tablets

Sample code

initial Total

final Observed

tablets taken

weight (mg)

weight (mg)

friability

f fria

o 0.15

Sample Code

Figure: 3.1 Friability of various brands of Pantoprazole tablets.

"Daffodil International University"

USP Specification for Friability of tablets:

Allowed range =1.0%

From the above results (Table 3.2) it is appeared that all brands of Pantoprazole tablets

complied with the BP / USP specification of friability.

3.3 Disintegration time

The disintegration time of five brands in phosphate buffer of pantoprazole are shown in table.

Before checking the disintegration in phosphate buffer they were treated in o.1 N HCl for 2

hours but no disintegration occur because of its enteric coating. The specification of

disintegration time is 5 to 30 minutes.

Table 3.3: Disintegration time of 5 brands of Pantoprazole tablets

T1(min) T2(min) T3(min) T4(min) T5(min) T6(min) Avg.

"Daffodil International University"

Disintegration time

Sample Code

Figure 3.2.: Disintegration time of various brands of Pantoprazole tablets.

It was seen from result (table) that none of the marketed Pantoprazole sample exceeded the

specification and therefore it can be said that e entire marketed sample complied with the

specification for tablet disintegration time.

3.4 Assay & Potency test

6 tablets of of each brands of pantoprazole were weighed and powdered. 10 mg of

pantoprazole sodium equivalent to pantoprazole was weighed and dissolved in 100 ml

ethanol then the solution was filtered. 1 ml of sample was taken and made the volume 10 ml.

Absorbance was measured at 289 nm using Shimadzu UV Spectrophotometer. Finally the

assay was calculated by using the following equation.

Absorbance of sample ´ Weight of standard

Assay of sample = ´ DF ´ Potency ´ Wt Avg

Absorbance of standard ´ Weight of sample

Where, Abs of Sam = Absorbance of sample

Wt of Std = Weight of standard

Abs of Std = Absorbance of standard

Wt of Sam = Weight of sample

DF = Dilution factor

P = Potency of standard

Wt Avg = Average weight of sample

"Daffodil International University"

Table: 3.4 Potency of P01

Abs of Wt of

Potency SD

Average potency = 98.14%

All the tablets meet the USP specification of potency

Table: 3.5 Potency of P02

Abs of Wt of

Potency SD

Average potency = 97.04%

All tablets meet the USP specification of potency

"Daffodil International University"

Table: 3.6 Potency of P03

Abs of Wt of

Potency SD

Average potency = 97.51%

All the tablets meet the specification of USP guideline of potency

Table: 3.7 Potency of P04

Abs of Wt of

Potency SD

Average potency = 95.76%

Two tablets don't meet the specification of the USP guidelines of potency.

"Daffodil International University"

Table: 3.8 Potency of P05

Abs of Wt of

Potency SD

Average potency = 94.60%

Two tablets do not meet the specification of the USP guidelines of potency.

Sample code

Figure 3.3: Average potency of different market preparations of Pantoprazole tablet.

"Daffodil International University"

3.5 Dissolution test

The dissolution rate of five brands of Pantoprazole tablets was determined. The observed

results were shown in table. The drug release% was plotted against the times, which give

dissolution curve.

USP specification: Not more than 10% in 0.1 N HCl in 2 hours & not less than 75% of the

labeled amount of pantoprazole to be dissolved in 45 minutes. the remaining Five Brands of

pantoprazole tablets meet the specification.

Table 3.9 Dissolution rate after 2 hrs. in 0.1 N HCl

Sample % of drug release

% o release 4

Sample Code

"Daffodil International University"

Figure 3.4 : Dissolution rate of different brands of Pantoprazole in 0.1N HCl after 2

Table 3.10 Dissolution rate of P01 in phosphate buffer

SI Time interval drug release %

Average % SD

Table 3.11 Dissolution rate of P02 in phosphate buffer

SI Time interval drug release %

Average % SD

Table 3.12 Dissolution rate of P03 in phosphate buffer

SI Time interval drug release %

Average % SD

"Daffodil International University"

Table 3.13 Dissolution rate of P04 in phosphate buffer

SI Time interval drug release %

Average % SD

Table 3.13 Dissolution rate of P05

SI Time interval drug release %

Average % SD

"Daffodil International University"

Figure 3.5: Dissolution Rate of Various Brands of Pantoprazole Tablets

All the brands meet the specification of the USP standard as they did not release more than

10% drug in 0.1 N HCL and all brands more than 75% within 45 minutes.

"Daffodil International University"

v Conclusion

Pantoprazole tablets have been analyzed to find their correct quality status. For this purpose,

the marketed sample of five brands of Pantoprazole tablets was analyzed by using established

methods and apparatus. RSD value of weight variation of different drugs is in the range of

(0.78-1.65)%, maximum friability of the tablets of all brands is 0.4%, maximum

disintegration time in phosphate buffer is 17.42 minutes, Maximum average potency among

the brands is 98.14 % and minimum potency is 94.60%, among the brands the maximum drug

release in 0.1N HCl is 6.06 , minimum dissolution in phosphate buffer after 45 minutes is

79.94% and the maximum is 88.03%. The result of friability, weight variation, and assay and

disintegration & dissolution tests of all marketed products comply with pharmacopoeal limit

except some parameter in case of lower listed company. The present study, although

performed on a limited scale yet on the basis of professional judgment the data reported in

this study can help the Drug Control Authority to get an idea about the quality status of the

marketed Pantoprazole preparations in Bangladesh.

"Daffodil International University"

v References

Ø "The theory and practice of industrial pharmacy", Lachman, Liberman, Kanig, third

Ø Gupta A. K. ,2001. "Introduction of Pharmaceutics-1" 3rd edition ,CBS Publishers &

Distributors, New Delhi, India. P.240-271

Ø Khan Dr.M.Shah Nawaz, "Assurance of Quality Pharmaceuticals", 1990, pp 33 – 35.

Ø British Pharmacopoeia 2009

Ø The United States Pharmacopea 2009

Ø Edwin K Jackson; Goodman & Gilman's 2007 ; PPI ; The Pharmacological Basis of

Ø 2007; Lippincott's Illustrated Reviews: Pharmacology; 5th Edition, Lippincott's-Raven

publishers NY; P 226-233

Ø Simler, R., Walsh, G., Mattaliano, R.J., Guziewicz, N., and Perez-Ramirez, B. (2008).

Maximizing Data Collection and Analysis During Preformulation of Biotherapeutic

Proteins. BioProcess International 6(10), 38-45.