Pii: s0266-3538(00)00101-9

Composites Science and Technology 60 (2000) 2037±2055

Sisal ®bre and its composites: a review of recent developments

Yan Li, Yiu-Wing Mai *, Lin Ye

Centre for Advanced Materials Technology (CAMT), Department of Mechanical & Mechatronic Engineering J07,

The University of Sydney, Sydney, NSW 2006, Australia

Received 4 December 1998; received in revised form 4 April 2000; accepted 19 April 2000

Sisal ®bre is a promising reinforcement for use in composites on account of its low cost, low density, high speci®c strength and

modulus, no health risk, easy availability in some countries and renewability. In recent years, there has been an increasing interest

in ®nding new applications for sisal-®bre-reinforced composites that are traditionally used for making ropes, mats, carpets, fancy

articles and others. This review presents a summary of recent developments of sisal ®bre and its composites. The properties of sisal

®bre itself, interface between sisal ®bre and matrix, properties of sisal-®bre-reinforced composites and their hybrid composites have

been reviewed. Suggestions for future work are also given. # 2000 Elsevier Science Ltd. All rights reserved.

Keywords: B. Electrical property; B. Interface; B. Mechanical property; B. Surface treatment; Ageing; Degradation; Natural±®bre composite; Sisal

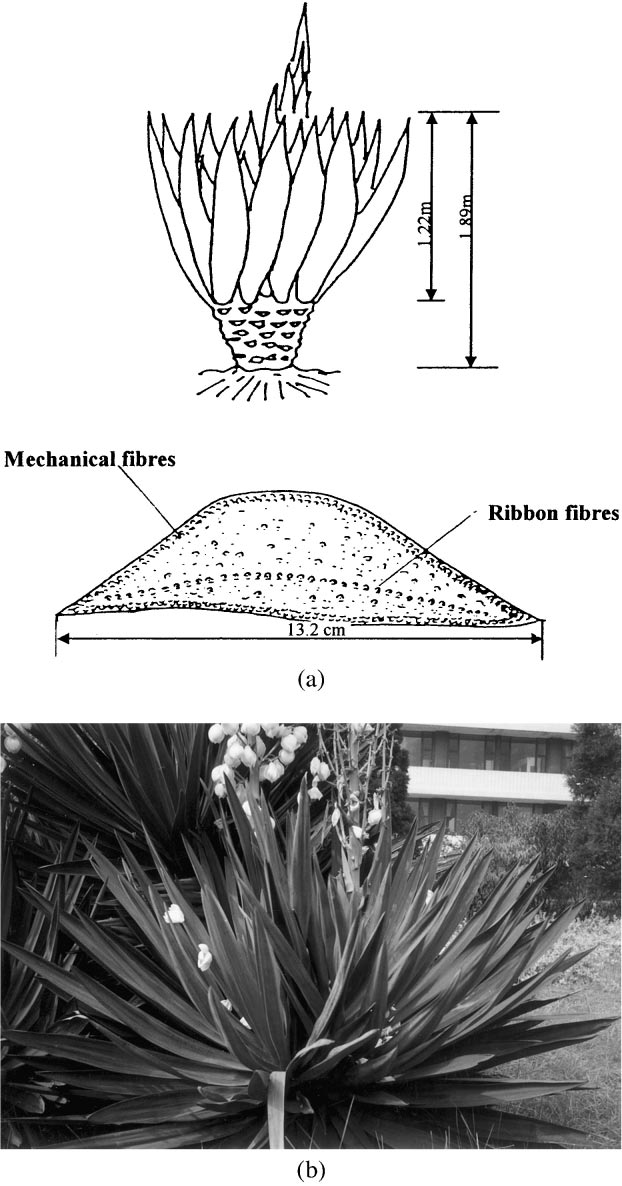

mostly extracted from the periphery of the leaf. They

have a roughly thickened-horseshoe shape and seldom

Sisal ®bre is one of the most widely used natural ®bres

divide during the extraction processes. They are the most

and is very easily cultivated. It has short renewal times

commercially useful of the sisal ®bre. Ribbon ®bres occur

and grows wild in the hedges of ®elds and railway tracks

in association with the conducting tissues in the median

[1]. Nearly 4.5 million tons of sisal ®bre are produced

line of the leaf. Fig. 1 shows a cross-section of a sisal leaf

every year throughout the world. Tanzania and Brazil

and indicates where mechanical and ribbon ®bres are

are the two main producing countries [2].

obtained [3]. The related conducting tissue structure of

Sisal ®bre is a hard ®bre extracted from the leaves of

the ribbon ®bre gives them considerable mechanical

the sisal plant (Agave sisalana). Though native to tropi-

strength. They are the longest ®bres and compared with

cal and sub-tropical North and South America, sisal

mechanical ®bres they can be easily split longitudinally

plant is now widely grown in tropical countries of

during processing. Xylem ®bres have an irregular shape

Africa, the West Indies and the Far East [3]. A sketch of

and occur opposite the ribbon ®bres through the con-

a sisal plant is shown in Fig. 1 and sisal ®bres are

nection of vascular bundles as shown in Fig. 2. They are

extracted from the leaves.

composed of thin-walled cells and are therefore easily

A sisal plant produces about 200±250 leaves and each

broken up and lost during the extraction process.

leaf contains 1000±1200 ®bre bundles which is com-

The processing methods for extracting sisal ®bres

posed of 4% ®bre, 0.75% cuticle, 8% dry matter and

have been described by Chand et al. [2] and Mukherjee

87.25% water [1]. So normally a leaf weighing about

and Stayanarayana [1]. The methods include (1) retting

600 g will yield about 3% by weight of ®bre with each

followed by scraping and (2) mechanical means using

leaf containing about 1000 ®bres.

decorticators. It is shown that the mechanical process

The sisal leaf contains three types of ®bres [3]:

yields about 2±4% ®bre (15 kg per 8 h) with good

mechanical, ribbon and xylem. The mechanical ®bres are

quality having a lustrous colour while the retting pro-

cess yields a large quantity of poor quality ®bres. After

extraction, the ®bres are washed thoroughly in plenty of

* Corresponding author. Tel.: +61-2-9351-2290; fax: +61-2-9351-

clean water to remove the surplus wastes such as chlor-

E-mail address:

[email protected] (Yiu-Wing Mai).

ophyll, leaf juices and adhesive solids.

0266-3538/00/$ - see front matter # 2000 Elsevier Science Ltd. All rights reserved.

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

Fig. 2. Cross-section of a ribbon-®bre bundle.

reinforced with spirally oriented cellulose in a hemi-cel-

lulose and lignin matrix. So, the cell wall is a composite

structure of lignocellulosic material reinforced by helical

micro®brillar bands of cellulose. The composition of the

external surface of the cell wall is a layer of lignaceous

material and waxy substances which bond the cell to its

adjacent neighbours. Hence, this surface will not form a

strong bond with a polymer matrix. Also, cellulose is a

hydrophilic glucan polymer consisting of a linear chain

of 1, 4-b-bonded anhydroglucose units [9] and this large

amount of hydroxyl groups will give sisal ®bre hydro-

philic properties. This will lead to a very poor interface

between sisal ®bre and the hydrophobic matrix and very

poor moisture absorption resistance.

Though sisal ®bre is one of the most widely used nat-

ural ®bres, a large quantity of this economic and

renewable resource is still under-utilised. At present,

sisal ®bre is mainly used as ropes for the marine and

agriculture industry [1]. Other applications of sisal ®bres

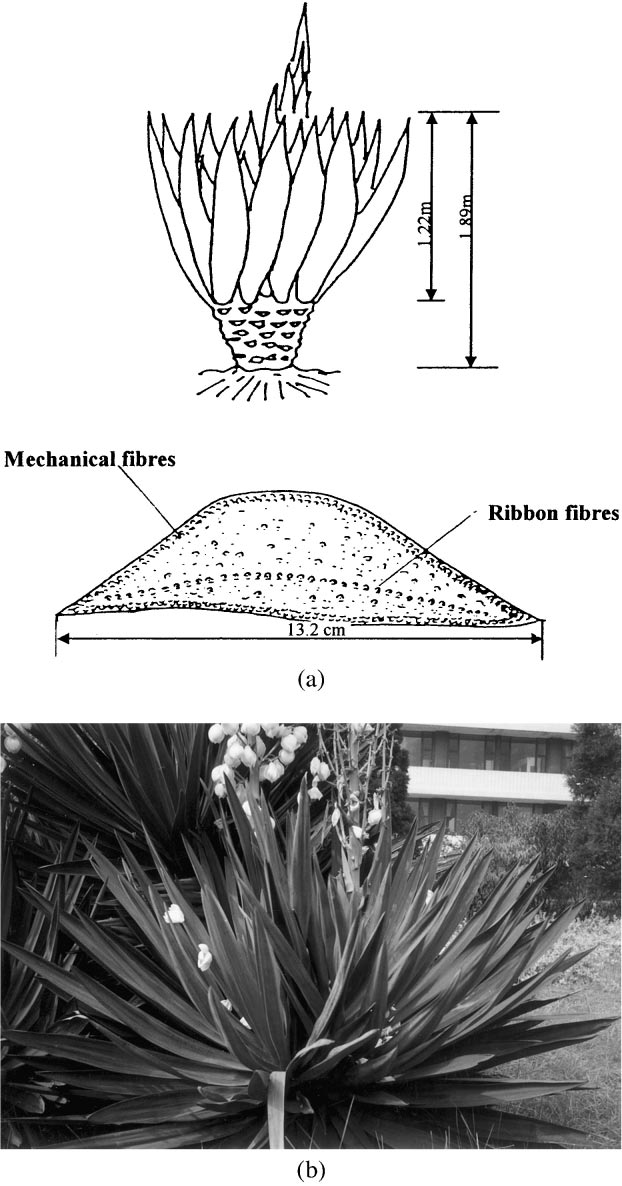

Fig. 1. (a) A sketch of sisal plant and the cross-section of a sisal leaf

[3]; (b) photograph of a sisal plant.

include twines, cords, upholstery, padding and mat

making, ®shing nets, fancy articles such as purses, wall

The chemical compositions of sisal ®bres have been

hangings, table mats, etc. [10]. A new potential applica-

reported by several groups of researchers [4±7]. For

tion is for manufacture of corrugated roo®ng panels

example, Wilson [4] indicated that sisal ®bre contains

that are strong and cheap with good ®re resistance [11].

78% cellulose, 8% lignin, 10% hemi-celluloses, 2%

During the past decade (1987±1998), the identi®cation

waxes and about 1% ash by weight; but Rowell [5]

of new application areas for this economical material

found that sisal contains 43±56% cellulose, 7±9% lignin,

has become an urgent task. The use of sisal ®bre as a

21±24% pentosan and 0.6±1.1% ash. More recently,

reinforcement in composites has raised great interest

Joseph et al. [6] reported that sisal contains 85±88%

and expectations amongst materials scientists and engi-

cellulose. These large variations in chemical composi-

neers. The major studies on sisal ®bres carried out dur-

tions of sisal ®bre are a result of its dierent source, age,

ing this 10-year period can be broadly divided into the

measurement methods, etc. Indeed, Chand and Hashmi

following topics:

[7] showed that the cellulose and lignin contents of sisal

vary from 49.62±60.95 and 3.75±4.40%, respectively,

. Properties of sisal ®bres: Mechanical, thermal and

depending on the age of the plant.

dielectric properties of sisal ®bre have been studied

The length of sisal ®bre is between 1.0 and 1.5 m and

in detail. X-ray diraction, IR, TG, SEM, DSC,

the diameter is about 100±300 mm [8]. The ®bre is actu-

DMA, etc., have been used to determine the char-

ally a bundle of hollow sub-®bres. Their cell walls are

acteristics of sisal ®bre and provide theoretical

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

support for processing and application of this

ulus per unit cost), it (41.67 GPakg/$) is almost the best

next to jute (43.33 GPakg/$) amongst all the synthetic

. Interface properties between sisal ®bre and matrix:

and cellulosic ®bres.

The main purpose here is to modify the ®bre-

surface structure by using chemical and thermal

treatment methods in order to enhance the bond

strength between ®bre and matrix and reduce

Generally, the strength and stiness of plant ®bres

water absorption of sisal ®bre.

depend on the cellulose content and the spiral angle

. Properties of sisal-®bre-reinforced composites: The

which the bands of micro®brils in the inner secondary

matrix used in sisal-®bre-reinforced composites

cell wall make with the ®bre axis. That is, the structure

include thermoplastics (polyethylene, polypropylene,

and properties of natural ®bres depend on their source,

polystyrene, PVC, etc.), thermosets (epoxy, polye-

age, etc. [12]. The tensile properties of sisal ®bre are not

ster, etc.), rubber (natural rubber, styrene±buta-

uniform along its length [3]. The root or lower part has

diene rubber, etc.), gypsum and cement. The

low tensile strength and modulus but high fracture

eects of processing methods, ®bre length, ®bre

strain. The ®bre becomes stronger and stier at mid-

orientation, ®bre-volume fraction and ®bre-sur-

span and the tip has moderate properties.

face treatment on the mechanical and physical

Table 2 shows the properties of sisal ®bres as reported

properties of sisal-®bre-reinforced composites have

by dierent researchers. Note that except for the struc-

been studied. Also, several theoretical models are

ture and properties of the natural ®bre itself, experi-

given to predict the properties of the composites.

mental conditions such as ®bre length, test speed, etc.,

. Sisal/glass-®bre-reinforced hybrid composites: To

all have some eects on the properties of natural ®bres

take advantage of both sisal and glass ®bres, they

have been added conjointly to the matrix so that

Mukherjee and Satyanarayana [1] studied the eects

an optimal, superior but economical composite

of ®bre diameter, test length and test speed on the ten-

can be obtained. The hybrid eect of sisal/glass

sile strength, initial modulus and percent elongation at

®bres on the mechanical properties have been stu-

the break of sisal ®bres. They concluded that no sig-

died and explained.

ni®cant variation of mechanical properties with change

in ®bre diameter was observed. However, the tensile

Papers published between 1987 and 1998 related to

strength and percent elongation at the break decrease

sisal ®bres are listed in Table 1. It can be seen that

while Young's modulus increases with ®bre length. With

research interest has changed from the ®bre itself to

increasing speed of testing, Young's modulus and tensile

sisal-®bre-reinforced composites and hybrid composites.

strength both increase but elongation does not show

The study of interface between sisal ®bre and matrix,

any signi®cant variation. However, at a test speed of

however, remains an important topic.

500 mm/min, the tensile strength decreases sharply.

These results have been explained in terms of the inter-

nal structure of the ®bre, such as cell structure, micro-

2. Properties of sisal ®bre

®brillar angle (20±25�), defects, etc. In rapid mechanical

testing, the ®bre behaves like an elastic body, i.e. the

crystalline region shares the major applied load result-

ing in high values of both modulus and tensile strength.

Compared to synthetic ®bres, the price of sisal ®bre

When the testing speed decreases, the applied load will

(0.36 US$/kg) is very low [3]. It is about one-ninth of

be borne increasingly by the amorphous region. How-

that of glass ®bre (3.25 US$/kg) and one-®ve hundredth

ever, at very slow test speeds, the ®bre behaves like a

of carbon ®bre (500 US$/kg). For speci®c price (mod-

viscous liquid. The amorphous regions take up a major

Number of papers published in the period (1987±1998) related to sisal ®bresa

Properties of sisal ®bres

6 [15±17,20±22]

Interface between sisal ®bre and matrix

Properties of sisal-ibre composites

13 [3,11,34±37,54, 57±59,61,62,64]

11 [26,32,33,42±44, 51±53,55,56]

Sisal/glass hybrid composites

a Data taken from Compendex (Computerised Engineering Index).

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

Properties of sisal ®bres reported by dierent researchers

Density (kg/m3) Moisture content (%) Tensile strength (MPa) Tensile Modulus (GPa) Maximum strain (%) Diameter (mm) Reference

portion of the applied load giving a low ®bre modulus

shows the results of sisal ®bres of dierent age at dif-

and a low tensile strength. But at very high strain rates

ferent temperature.

(�500 mm/min), the sudden fall in tensile strength may

For electrical applications, the dielectric properties of

be a result of the presence of imperfections in the ®bre

sisal ®bre at dierent temperature and frequency have

causing immediate failure.

also been studied [16]. Increase of frequency decreases

In Ref. [1], the micro®brillar angle and number of

the dielectric constant "0 value, while increase of tem-

strengthening cells in the sisal ®bres did not show any

perature increases "0 at all frequencies. Increasing the

appreciable variation in ®bre diameter. Hence, no

plant age shifts the dissipation factor ( tan �) peak to

appreciable change in values of Young's modulus and

higher temperature. These phenomena were explained

tensile strength were observed. As the test length

on the basis of structural changes. Water absorbed by

increases, the number of weak links or imperfections

sisal ®bres has OHÿ anions which act as dipoles. Other

also increases, thus resulting in reduction in tensile

than OHÿ anions, there are several impurities and ions

strength. However, with increasing ®bre length, sisal

on the ®bre. These dipoles and ions contribute to the "0

oers a higher resistance to applied stress as a result of

and tan � behaviours of sisal ®bres. At low frequencies,

the involvement of more oriented cellulosic ®bres. This

high "0 and tan � values in sisal ®bre are caused by the

probably also accounts for the higher modulus of the

dipolar contribution of absorbed water molecules. "0

®bres at longer test lengths. The reason for such beha-

values at intermediate frequencies are the result of con-

viour by the characteristics of natural ®bres such as

tributions from space charge polarisation. At high fre-

multi-cellular structures, visco-elastic nature and non-

quencies, the contribution of polarisation of absorbed

uniform structural inhomogeneity.

water molecules and space charge decreases and elec-

Chand et al. [12] reported the eects of testing speed

tronic and atomic polarisation becomes operative.

and gauge length on the mechanical properties of other

Increase in temperature aects the mobility of ions and

kinds of natural ®bres (sun-hemp ®bres). Their results

consequently changes the ionic contributions. The tem-

support the ®nding of Ref. [1], though the magnitudes

perature dependence of the dielectric behaviour of sisal

are much lower than those of sisal ®bres. (For example,

®bre is shown in Fig. 3.

when the gauge length is 50 mm and testing speed is 50

Yang et al. [17] used IR, X-ray diraction and TG to

mm/min, the tensile strength of sisal ®bre is 759 MPa.

study the eect of thermal treatment on the chemical

However, for sun-hemp ®bre, the tensile strength is only

structure and crystallinity of sisal ®bres. They concluded

that the IR spectrum did not change below 200�C

The mechanical properties of sisal ®bres obtained

treatment while density and crystallinity increased. This

from dierent age at three dierent temperature were

means that the chemical structure of sisal ®bres will not

investigated by Chand and Hashmi [15]. The tensile

change below 200�C while the degree of crystallinity can

strength, modulus and toughness (de®ned as energy

be increased and hence the density. There was a slight

absorption per unit volume) values of sisal ®bre

weight loss (�2%) below 200�C probably caused by the

decrease with increasing temperature. The relative eect

evaporation of water absorbed by sisal ®bres, sub-

of plant age on these mechanical properties is less pro-

stances of low boiling point and others that can be

minent at 100�C than at 30�C. This is attributed to the

decomposed below this temperature. However, the large

more intense removal of water and/or other volatiles (at

amounts of cellulose, semi-cellulose and glucans were

100�C) originally present in the ®bres, which otherwise

not lost. Also, they found that thermal decomposition

act as plasticising agents in the chains of the cellulose

of sisal ®bre could be divided into three stages. The

macromolecules. It is, however, noted that at 80�C both

thermal behaviours are essentially identical for heat

tensile strength and modulus decrease with age of the

treatment between 150 to 200�C. Hence, thermal treat-

plant. This trend is dierent to testing at 100�C. Table 3

ment of sisal ®bre can be carried out below 200�C.

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

Comparisons of mechanical properties of sisal ®bres with dierent age at dierent temperature [15]

Toughness per unit volume (MJ/m3)

Tensile strength (MPa)

Tensile modulus (GPa)

Results of TG of treated and untreated sisal ®bresa,b

t1 (�C) w1 (%) t2(�C) w2 (%) t3 (�C) w3 (%)

150�C/4 h treated

200�C/0.5 h treated 61

a Three-stage thermal decomposition [17].

b ti ith stage decomposition temperature; wi ith stage percentage

weight remnant.

able levels by better wetting and chemical bonding

between ®bre and matrix.

3.1. Treatment of sisal ®bre surface

Most previous studies were focused on ®bre-surface

treatment methods and the resultant eects on the phy-

sical and mechanical properties of dierent ®bre-matrix

composite systems. But what will happen to the ®bres

after being treated? Several investigators [20±22] have

studied the surface morphology, mechanical and degra-

dation properties of the treated ®bres.

Fig. 3. Variation of (a) dielectric constant "0 and (b) dissipation factor

Yang et al. [20] studied the relationship of surface

tan � with temperature in 2-year-old plant ®bres [17].

modi®cation and tensile properties of sisal ®bres. Their

modi®cation methods include: alkali treatment, H2SO4

treatment, conjoint H2SO4 and alkali treatment, benzol/

Table 4 shows the TG results of untreated and heat-

alcohol dewax treatment, acetylated treatment, thermal

treated sisal ®bres.

treatment, alkali-thermal treatment and thermal-alkali

treatment. The results are summarised in Table 5.

Thermal treatment (at 150�C for 4 h) seems to be the

3. Interface modi®cations

most desirable method in terms of strength and mod-

ulus properties because of the increased crystallinity

Interfaces play an important role in the physical and

(from 62.4% for untreated to 66.2% for 150�C/4 h

mechanical properties of composites [18,19]. The

treated) of sisal ®bres. When the temperature reaches

hydroxyl groups which occur throughout the structure

200�C, the tensile properties will drop greatly as a result

of natural ®bres make them hydrophilic, but many

of the degradation of ®bres. Other treatments increase

polymer matrices are hydrophobic so that sisal-polymer

the ductillity of sisal ®bres substantially but decrease the

composites have poor interfaces. Also, the hydrophilic

sisal ®bres will absorb a large amount of water in the

To improve the moisture-resistance, Chand et al.

composite leading to failure by delamination. Adequate

acetylated sisal ®bre and studied its tensile strength [23].

adhesion across the interface can be achieved at desir-

It was shown that acetylation could reduce the moisture

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

. Coupling agent 3:

Eect of treatment methods on tensile properties of sisal ®bres [20]

Treatment methods Tensile strength Tensile modulus Elongation

Acetic acid+alkali

. Coupling agent 4:

content from 11 to 5.45%. However, the tensile strength

of acetylated sisal ®bre was reduced from 445 to 320

MPa caused by the loss of the hemi-cellulose in the ®bre

during acetylation.

Surface modi®cation of sisal ®bre using coupling

agents was also studied by Singh et al. [24]. Sisal ®bres

were cut into short lengths (6 cm) and washed with dis-

tilled water to remove water solubles from the ®bre

surface completely. After being air-dried they were

The hydroxyl groups attached to the glucose units of

heated to 80�C for 8 h to remove excess surface moist-

the cellulose will react with these coupling agents in the

ure. Then these ®bres were treated by dipping into the

presence of moisture by substituting the right part of the

coupling-agent solution and stirring slowly for 0.5 h.

dashed lines shown on the chemical structures of the

After that, the treated ®bres were washed with solvent

coupling agents.

to remove compounds not covalently bonded to the

The eects of these coupling agents on the moisture

®bres and then kept at 80�C in an oven for 4 h to con-

content in sisal ®bre are obtained and discussed. It is

stant weight.

clear that moisture absorption of surface-treated ®bres

The four coupling agents used were: N-substituted

has been reduced signi®cantly by providing hydro-

methacrylamide (coupling agent 1); gamma-methacry-

phobicity to the surface via long-chain hydrocarbon

loxypropyl trimethoxy silane (coupling agent 2); neo-

attachment. In addition, these coupling agents penetrate

the cell wall through surface pores and deposit in the

(coupling agent 3); and neopentyl(diallyl)oxy, triacryl

inter®brillar regions and on the surface, restricting fur-

zironate (coupling agent 4). Their chemical structures

ther ingress of moisture.

and possible interactions with sisal are as follows:

3.2. Treatment of ®bre/matrix interfaces

. Coupling agent 1:

To make good use of sisal-®bre reinforcement in

composites, ®bre-surface treatment must be carried out

to obtain an enhanced interface between the hydrophilic

sisal ®bre and the hydrophobic polymer matrices.

Modi®cations of interfaces between sisal ®bre and

polyester, epoxy, polypropylene, etc., have been studied.

Both mechanical and moisture absorption resistance

properties can be improved. These results are described

in the following sub-sections.

. Coupling agent 2:

3.2.1. Sisal/polyester composites

The properties of sisal-®bre-reinforced polyester

composites can be improved when sisal ®bres were sui-

tably modi®ed with surface treatment [24]. The mod-

i®cation methods have been discussed in Section 3.1.

In the work by Singh et al. [24], it was explained that

the modi®ed interphase' is much less sti than the resin

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

matrix and provides a deformation mechanism to reduce

3.2.2. Sisal/epoxy composites

interfacial stress concentration [25]. Further, it may also

For the interface between sisal ®bres and epoxy,

prevent ®bre/®bre contacts, hence removing the sources

Bisanda and Ansell [8] adopted silane treatment meth-

of high stress concentrations in the ®nal composites.

ods to improve the adhesion and moisture resistance

The eect of ®bre-surface treatment on the mechan-

properties. The ®bres were ®rst dewaxed in 2000 ml

ical properties under wet environment has also been

solution of benzene and alcohol (methylated spirit), ratio

studied in [24]. The results in Fig. 4 clearly show that by

1:1, by soaking batches of about 200 g of sisal ®bres,

improving interfacial adhesion the moisture-induced

300 mm long, in a sealed glass vessel. The ®bres were

degradation of composites can be reduced. Treated ®bre

soaked for 24 h, rinsed in alcohol and distilled water.

composites absorb moisture at a slower rate than the

These ®bres were then mercerized by soaking in a 0.5 N

untreated counterparts, probably because of the forma-

solution of sodium hydroxide, for about 72 h, rinsed in

tion of a relatively more hydrophobic matrix interface

distilled water and dried.

region by co-reacting organo-functionality of the cou-

To study the moisture resistance of composites, the

pling agents with the resin matrix. Though signi®cant

®bres were treated using silane that had been diluted to

reductions in tensile strength (30±44%) and ¯exural

5% in methylated spirits. A 0.1 M solution of ceric

strength (50±70%) were observed for both untreated

ammonium nitrate (CAN) was used as catalyst. The

and surface-treated sisal composites (Table 6 and Fig.

®bres were treated in batches by soaking about 150 g of

4), the strength retention of surface treated composites

the mercerized ®bres in 1500 ml of the silane/CAN

is higher than that of composites containing untreated

solution (2:1), for about 24 h at room temperature. The

sisal ®bres. Fig. 4 also shows that N-substituted metha-

®bres were then rinsed in distilled water and dried.

crylamide treated sisal-®bre-reinforced polyester compo-

The reaction mechanisms are as follows. First, silane

sites generally exhibit better mechanical properties under

reacts with water to form a silanol and an alcohol:

dry and wet conditions. It should, however, be noted in

Table 6 that with sisal ®bres treated by N-substituted

methacrylamide and silane have relatively lower void

NH2

CH23Si

OC2H53 3H2O

contents compared to other ®bre-treated composites.

HO3Si

CH23NH2 3

C2H5OH

Then, in the presence of moisture, the silanol reacts

with the hydroxyl groups attached to the glucose units

(G) of the cellulose molecules in the cell wall, thereby

bonding itself to the cell wall with further rejection of

NH2

CH23Si

OH3 H2O GOH

NH2

CH23Si

OH2OG 2H2O

It is found that the treatment of sisal ®bres in silane,

Fig. 4. Eect of wet environment on tensile strength of sisal/polyester

preceded by mercerization, provides improved wettabil-

composites (®bre content �50 vol.%) for 35 days: 1, untreated; 2, N-

substituted methyacrylamide treated; 3, silane treated; 4, titanate

lity, mechanical properties and water resistance of sisal-

treated; 5, zirconate treated. RH, relative humidity [24].

epoxy composites. The results are shown in Table 7.

Eect of surface treatments of sisal ®bres on the properties of sisal/polyester compositesa [24]

Zirconate treated

methacrylamide treated

Tensile strength (MPa)

Tensile modulus (GPa)

Energy to break (MJ/m2) �105

Flexural strength (MPa)

Flexural modulus (GPa)

a Fibre content � 50 vol%.

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

Mechanical and physical properties of sisal/epoxy compositesa [8]

Compressive strength

Flexural strength

Water absorbed (%)

a Fibre volume fraction: 0.4.

Mercerization has greatly improved resin pick-up, or

initially alkali treated and then grafted with vinyl acid in

wettability, of the ®bres because of the increase in den-

an acid medium under N2 atmosphere with a grafting

sity of the composite. It is believed that, by providing

rate of 5.7%. The mechanical behaviour, water-resis-

additional sites of mechanical interlocking, this treat-

tance and ¯exible fracture morphology of short sisal/

ment leads to improvement of interfacial bonding,

phenol formaldehyde composites have all been mea-

hence promoting resin/®bre interpenetration at the

sured. The results show that cohesiveness between rigid

interface. The high hydrophobic resin pick-up could

sisal ®bre and brittle phenol formaldehyde can be

also account for the reduction in water absorption and

improved when sisal ®bre is treated with silane so that

hence improved mechanical properties under wet con-

the mechanical properties of the composites can be

increased. Water-resistance of the composites can be

Though treatment of sisal ®bres in silane preceded by

improved after being treated by grafting and silane

mercerization produces very little change in the

mechanical properties of dry composites, mechanical

performance of wet composites, and hence water resis-

3.2.4. Sisal/polyethylene composites

tance, can be improved. The treatment in 100% silane

Owing to the increasing use of thermoplastics, sisal

produces ®bres that are almost hydrophobic. This may

®bre reinforced-thermoplastics have become increas-

be a result of improved interfacial bonding arising from

ingly important. Joseph et al. [6] reported the eect of

the use of the silane. Water molecules at the interface

chemical treatment on the tensile properties of short-

tend to replace the resin-®bre covalent bond by weaker

sisal-®bre reinforced-polyethylene (PE) composites (both

hydrogen bonds, hence silane plays an important role in

randomly and unidirectionally oriented) and analysed

reducing water absorption in cellulosic-®bre-reinforced

the mechanisms of dierent treatment methods.

The treatment methods and their mechanisms are:

Sisal ®bres have a central hollow region, the lumen,

which gives access to water penetration by capillarity,

a. Alkali treatment: Alkali treatment can remove

especially when composites have high ®bre content. So,

natural and arti®cial impurities and produce a

although silane treatment can create a hydrophobic

rough surface topography. In addition, alkali

®bre surface, it is not possible to prevent water from

treatment leads to ®bre ®brillation, i.e. breaking

entering the composite by capillary action, as long as

down the ®bre bundle into smaller ®bres. This

the ®bre ends are exposed. It is recommended that, for

increases the eective surface area available for

practical purposes, it may be necessary to seal o the

wetting by the matrix resin. Hence, increasing the

external surfaces by water-repellents so as to keep water

®bre aspect ratio caused by reduced ®bre diameter

uptake in the composite to a minimum.

and producing a rough surface topography oer

better ®bre/matrix interface adhesion and increase

3.2.3. Sisal/phenol formaldehyde composites

in mechanical properties.

Yang et al. [26] using NaOH, silane (3-aminopropyl-

b. Isocyanate treatment: The hydrophilic nature of

triethoxy silane), chemical grafting and thermal treat-

sisal ®bres can be reduced by treating the ®bres

ment methods studied the eects on sisal/phenol

surface with urethane derivative of cardanol

formaldehyde composites. Alkali and thermal treatment

(CTDIC) because of the linkage of the long chain

methods have already been discussed in Section 3.1 [20].

structure of CTDIC to the cellulosic ®bres. This

For silane treatment, the ®bre was ®rstly treated by

makes sisal ®bres compatible with the PE matrix,

alkali and then immersed in the silane alcohol solution.

thus resulting in a strong interfacial bond between

After that, it was air-dried and followed by heating at

these two constituents with improved mechanical

100�C. While for chemical grafting the sisal ®bre is

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

c. Peroxide treatment: The function of peroxide

. Sisal-®bre-reinforced thermosets

treatment is that it can graft PE on to the cellulose

. Sisal-®bre-reinforced thermoplastics

surface. The grafting reaction is a result of the

. Sisal-®bre-reinforced rubbers

peroxide-initiated free radical reaction between the

. Sisal-®bre-reinforced cement and gypsum

PE matrix and cellulose ®bres as shown below:

The number of papers published since 1987 are listed

in Table 8. It is shown that the most widely used matrix

RO: PE-H ! ROH PE:

for sisal-®bre-reinforced composites has changed from

gypsum and cement to rubber and polyethylene. Ther-

RO: Cellulose-H ! ROH Cellulose:

mosetting matrices such as epoxy and polyester have

also been used for sisal-®bre-reinforced composites.

PE: Cellulose: ! PE-Cellulose

4.1. Sisal-®bre-reinforced thermoset matrices

The tensile strength of the composites increases with

peroxide concentration up to a critical level depending on

The most widely used thermosetting matrix reinforced

the ®bre content and then remains constant. The exis-

by natural ®bres is polyester [27±30]. Compression

tence of a critical concentration of peroxide suggests that

moulding is the most widely used and convenient

the peroxide-initiated grafting reactions terminate when

method to make these composites, whether the ®bre is

the ®bres are covered with grafted PE and excess peroxide

long or short. The tensile and impact properties of this

causes some crosslinking of the PE molecules themselves.

kind of composites have been obtained by Sanadi et al.

d. Permanganate treatment: Permanganate is thought

It is shown that the tensile strength and elastic mod-

to induce grafting reactions between sisal ®bres

ulus of the composites containing up to 40% ®bre-

and PE matrix [6]. Joseph et al. have attempted to

volume fraction (Vf) increase linearly with Vf in good

explain the initiating graft copolymerisation but

agreement with the rule of mixtures. The work of

the conditions for this to occur are quite critical

fracture, as determined by Izod impact test, also

and cannot be ful®lled easily. (It is also dicult to

increases linearly with Vf. Analysis of the energy-

justify the di-valency of H in reactions given in

absorption mechanisms during impact fracture shows

[6].) Instead, oxidisation between permanganate

that ®bre pull-out and interface fracture are the major

and sisal ®bre will take place. So, the mechanism

contributors to the high toughness of these composites.

for improvement of the interfacial properties by

This result indicates that sisal ®bres have potential to

permanganate treatment is that the permanganate

produce inexpensive materials with high toughness.

roughens the ®bre surface and produces mechan-

Comparison of the impact properties of dierent nat-

ical interlocks with the matrix. Hence, the inter-

ural ®bre-reinforced composites, including sisal, pine-

facial bonding between permanganate treated sisal

apple, banana and coir shows that sisal-®bre composites

®bre and matrix is improved.

possess the highest impact toughness owing to the opti-

mal micro-®brillar angle of the ®bre (21� for sisal, 12�

The permanganate concentration used is a critical

factor for the mechanical properties of the composite. It

is observed that the tensile strength reaches a maximum

Number of papers related to sisal ®bres published in the period (1987±

at a permanganate concentration of 0.055% and then

decreases sharply with further increase in permanganate

1987±1990 1991±1994 1995±1998

concentration. This is caused by the degradation of cel-

lulosic ®bres at high permanganate concentration.

Tensile properties of these sisal/PE composites with

[6, 44,51±52,67±68]

dierent treatment methods were compared. It appears

that the increase in properties as a result of these treat-

ments are in the order: DCP (dicumyl peroxide)

4. Properties of sisal-®bre-reinforced composites

According to the types of matrices used in sisal-®bre-

reinforced composites, they can be divided into the

following categories:

a Data taken from Compendex (Computerised Engineering Index).

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

for banana, 14� for pineapple and 45� for coir). It has

of these composites rather than sisal-®bre-reinforced

been proven by Gordon and Jeronimidis [31] that the

thermosets. Such properties include mechanical, envir-

toughness of composites increases with the micro-

onmental, electrical and dynamic.

®brillar angle of the ®bres and reaches a maximum at

15±20�. It will then decrease with increasing angle. The

4.2.1. Processing methods

optimal micro-®brillar angle of sisal ®bre (21�) leads to

The mixing methods so far used are: melt mixing and

better impact resistance with a work of fracture of 98.7

solution mixing. In melt mixing, the ®bre is added to a

KJ/m2 when the ®bre-volume fraction is 50%. For the

melt of thermoplastics and mixing is performed using a

same volume fraction of pineapple ®bres, this is 79.5

mixer at a speci®ed temperature and speed for a speci-

KJ/m2; for banana and coir ®bres, they are 51.6 and

®ed time. Then the mix is taken out from the mixer

43.5 KJ/m2, respectively. When compared to synthetic

while hot and is extruded using an injection moulding

®bre composites, the speci®c impact work of fracture

machine as long and thick rods.

for the natural ®bre composites is not much worse. The

In the solution mixing method, the ®bres are added to

speci®c work of fracture (ie toughness per unit density)

a viscous solution of thermoplastics in a solvent in a

of 60% volume fraction sisal ®bre/polyester composites

stainless-steel beaker with a stainless-steel stirrer. The

is 115 KJ mÿ2/g, while for ultra-high-modulus poly-

temperature is maintained for some time and the mix

ethylene (UHMPE) and E-glass ®bres, these values are

transferred to a ¯at tray and kept in a vacuum oven to

125 and 165 KJ mÿ2/g, respectively.

remove the solvent. The solution-mixing procedure

Rong et al. studied the eect of ®bre pre-treatment

avoids ®bre damage that normally occurs during blend-

and water absorption on the impact properties of sisal

ing of ®bre and thermoplastics by melt-mixing [34].

®bre reinforced polyester and epoxy matrices [32,33].

Generally, randomly oriented sisal-®bre-reinforced

Three ®bre-surface treatment methods including alkali

composites are prepared by standard injection moulding

treatment, coupling agent treatment and heat treatment

of the blends. Oriented sisal composites are processed

were used. They indicated that ®bre-surface treatment

by aligning the long extruded rods with compression

has a strong eect on the impact behaviour of the com-

posites and the eects are dierent for dierent matri-

Polyethylene is the most widely used thermoplastics

ces. It is observed that ®bre pull-out is the major

matrix [34±37]. For other natural ®bre composites,

contributor to the energy absorption. Increased ®bre-

polypropylene is also a major matrix material [38±41].

tensile strength promoted by thermal treatment can

Recently, sisal ®bre-reinforced polystyrene and PVC

increase the impact performance of the composites.

have also been studied [42,43].

Water absorption in sisal ®bre composites is mainly

caused by the ®bres and leads to a very poor interface

4.2.2. Properties of sisal ®bre reinforced polyethylene

between the sisal ®bre and the matrix. Dierent matrix

4.2.2.1. Mechanical properties. Joseph et al. [35] studied

systems have dierent interface characteristics. Gen-

the tensile properties of short sisal ®bre/polyethylene

erally, water absorption in sisal/polyester composite is

composites in relation to processing methods and the

two to three times that in sisal/epoxy composite and this

eects of ®bre content, length and orientation (see

leads to their dierent impact properties. For sisal/epoxy

Tables 9 and 10). As expected, the tensile properties

composite, the impact strength improves with water

show a gradual increase with ®bre length reaching a

absorption as a result of an acceptable level of interface

maximum at about 6 mm (12.5 MPa) and then decrease

debonding, but for sisal/polyester composites, the impact

(e.g. 10.24 MPa at 10 mm). Unidirectional short ®bres

strength decreases through the complete destruction of

achieved by extrusion enhance the tensile strength and

the interface.

elastic modulus of the composites along the axis of ®bre

From the viewpoint of interface enhancement,

alignment by more than two-fold compared to ran-

Bisanda and Ansell [8] studied the mechanical and phy-

domly oriented ®bre composites.

sical properties of sisal/epoxy composites and Yang et

Dierent processing methods lead to dierent extent

al. [26] investigated sisal/phenol formaldehyde compo-

of ®bre damage, dierent ®bre-length distribution and

sites. The properties of these two composite systems

hence dierent mechanical properties. The eect of ®bre

have already been discussed in Sections 3.2.2 and 3.2.3.

length on the mechanical properties can be explained by

the fact that long ®bres tend to bend or curl during

4.2. Sisal-®bre-reinforced thermoplastics matrices

moulding. This causes a reduction in the eective length

of the ®bre below the critical ®bre length in a particular

In recent years, sisal-®bre-reinforced thermoplastics

direction and hence a decrease of mechanical properties.

composites have gained much more interest among

The experimental tensile properties of short sisal-

materials scientists and engineers than thermosets

®bre-reinforced LDPE with dierent ®bre-volume frac-

because of their low cost and recyclable properties. Many

tions have been compared with existing theories of

papers have now been published to study the properties

reinforcement [44]. The models selected were series and

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

Variation of tensile properties of melt mixing composite (MMC) and solution mixing composite (SMC) with ®bre content [35]a

Elongation at break

Elongation at break

a Average ®bre length: 5.8 mm; values given in parentheses are the properties of unidirectionally aligned ®bre composites.

c x

MmVm Mf Vf

1 ÿ x

Variation of tensile properties of solution mixing composite (SMC)

with repeated extrusion of the blends [35]a

Elongation at break

c x

TmVm Tf Vf

1 ÿ x

where x is a parameter which determines the stress

transfer between ®bre and matrix. It is always assumed

that x is determined mainly by ®bre orientation, ®bre

a Average ®bre length: 5.8 mm, ®bre content: 20 wt.%.

length l and stress ampli®cation eect at the ®bre ends.

This model is in fact a combination of the parallel and

series models.

parallel [45], Hirsch [46], Halpin-Tsai [47], modi®ed

Halpin-Tsai [48], Cox [49] and modi®ed Bowyer and

. Halpin-Tsai model [47]

Bader [50] models. These models are given below for

. Parallel and series model [45]:

Mc MfVf MmVm

Tc TfVf TmVm

where A is a factor determined by ®bre geometry, ®bre

distribution and ®bre-volume fraction. � and �� account

for the relative moduli and strength of ®bre and matrix,

. Modi®ed Halpin-Tsai equation [48]

where M, T and V are Young's moduli, tensile strength

and volume fraction, respectively. The subscripts c, m

and f represent composite, matrix and ®bre, respec-

. Hirsch's model [46]

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

where lc is the critical ®bre length.

Experimental results and theoretical values obtained

from the above models were compared. It is observed

that all models except the series and parallel models

The modi®ed Halpin-Tsai equation includes the max-

show reasonable agreement with experimental data of

imum packing fraction, �max, of the reinforcement. �max

longitudinally oriented composites, especially at low

equals 0.785 for square arrangement of ®bres, 0.907 for

®bre-volume fractions. But, the Hirsch and modi®ed

hexagonal array of ®bres and 0.82 for random packing

Bowyer and Bader equations show the closest agree-

of ®bres. � and �� are given by Eqs. (9) and (10),

ment with test results. However, agreement with the

respectively, and depends on the particle packing

experimental data of randomly oriented composites

fraction. l=d is the ®bre aspect ratio.

cannot be accurately predicted with these two models as

shown in Figs. 5 and 6. All theoretical models indicate

that the tensile properties of short-®bre-reinforced com-

posites strongly depend on ®bre length, ®bre volume

fraction, ®bre dispersion, ®bre orientation and ®bre/

c Mf Vf

1 ÿ

matrix interfacial strength.

4.2.2.2. Dynamic mechanical properties. The eects of

®bre length, orientation, volume fraction and ®bre sur-

face treatment on the dynamic mechanical properties of

sisal-®bre-reinforced PE including storage modulus, loss

modulus and damping characteristics have also been

where r is the radius of the ®bre, Gm is the shear mod-

studied [34]. It is found that addition of 10% of short

ulus of matrix, Af is the area of the ®bre and R is the

sisal ®bres into LDPE increases the storage moduli and

centre-to-centre distance of the ®bres. For hexagonally

loss moduli of the composites, levelling o at higher

volume fraction. This is believed to be caused by the

increasing ®bre-to-®bre interaction at high volume frac-

R

p 1

tions resulting in poor dispersion. Both storage and loss

moduli decrease with increase of temperature. The

damping properties of the composites decrease with

For square packed ®bres

addition of ®bres and are strongly in¯uenced by ®bre

orientation. The storage and loss moduli of randomly

oriented composites were intermediate between those of

longitudinally and transversely oriented composites.

The in¯uence of ®bre length indicates that a critical

. Modi®ed Bowyer and Bader's model [50]

length of 6 mm is needed to obtain maximum dynamic

moduli. This suggests that a critical length exists for

Bowyer and Bader's model indicates that the tensile

maximum stress transfer between ®bre and matrix. The

strength of short-®bre-reinforced thermoplastic compo-

storage and loss moduli of the isocyanate-treated com-

sites is the sum of contributions from sub-critical and

posites are higher than those of the untreated composites

super-critical ®bres and that from the matrix.

as a result of the improved ®bre/matrix interface adhe-

sion. Some dynamic mechanical results are shown in

Mc MfK1K2Vf MmVm

Figs. 7 and 8.

4.2.2.3. Electrical properties. The electrical properties of

Tc TfK1K2Vf TmVm

sisal-®bre-reinforced LDPE have been studied with

respect to the eects of frequency, ®bre content and

where K1 is the ®bre orientation factor and K2 is the

®bre length on the dielectric constant, volume resistivity

®bre length factor. If ®bre length l > lc,

and dielectric loss factor [51]. The dielectric constant

increases steadily with increasing ®bre content for all

frequencies in the range 1 to 107 Hz. It is also noted that

dielectric constant decreases with increase of ®bre length

If ®bre length l < lc,

and frequency. Maximum dielectric constant values are

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

Fig. 5. Variation of experimental and theoretical tensile properties of

Fig. 8. Variation of loss moduli with temperature for untreated (ran-

randomly oriented composites as a function of ®bre-volume fraction

domly oriented) sisal/LDPE composites at dierent ®bre content.

[44] ( Ð ) strength (- - - -) modulus.

Fibre length=6 mm, frequency=10 Hz [34].

dielectric constants of the latter composites with fre-

quency and ®bre content are smaller as a result of their

lower interfacial polarisation. The dielectric constant,

dielectric loss factor and electrical conductivity of 25%

sisal/LDPE can be increased considerably by adding

5% carbon black. The electrical conductivity of hydro-

phobic LDPE can also be improved by mixing it with

hydrophilic ligno-cellulosic ®bres. Solution mixing

technique has no adverse eects. Finally, it is important

to mention that a 25% sisal/LDPE composite contain-

ing 5% carbon black can be used in anti-static applica-

tions to dissipate static charges.

Fig. 6. Variation of experimental and theoretical tensile properties of

randomly oriented composites as a function of ®bre length [44]. For

keys, see Fig. 5.

4.2.2.4. Ageing properties. The environmental proper-

ties of sisal-®bre composites are very important because,

as a natural ®bre, sisal ages and causes degradation. The

eects of aging on the physical and mechanical proper-

ties of sisal-®bre-reinforced polyethylene composites

have been studied [52]. The tensile properties and

dimensional stability are evaluated under two dierent

ageing conditions: one is by immersing samples in boil-

ing water for 7 h under atmospheric pressure; and the

other is by heating the samples at 70�C in an air circu-

lating oven for 7 days. Both cardanol derivative of tol-

uene di-isocyanate (CTDIC) treated and untreated sisal-

®bre-reinforced composites have been studied. The age-

ing properties of the sisal composites are also compared

Fig. 7. Storage moduli and mechanical-loss factor versus temperature

to those of glass-®bre composites aged under identical

for untreated (randomly oriented) sisal/LDPE composites at dierent

conditions. It is concluded that CTDIC-treated compo-

®bre content. Fibre length=6 mm, frequency=10 Hz [34].

sites showed better mechanical properties and dimen-

sional stability as compared to untreated composites as

obtained at low frequencies. Sisal/LDPE composites of 1

a result of the existence of an eective interfacial bond

mm ®bre length and 30% ®bre content have the highest

between ®bre and matrix. Better dimensional stability is

values of dielectric constants at all frequencies. The

oered by glass/LDPE composite because of the

volume resistivity values decrease with increase of fre-

hydrophobic nature of the glass ®bre. With suitable

quency and ®bre content, i.e. the electric conductivity of

®bre-surface treatment, mechanical properties such as

composites are greater than neat LDPE. When com-

strength and elastic modulus of sisal/LDPE composites

pared to glass/LDPE composites, the same trend in elec-

can be improved to comparable levels as those of glass/

trical properties is observed, but the changes of

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

4.2.3. Properties of sisal ®bre-reinforced polystyrene

leads to the poor immersion of ®bres in the PVC matrix.

Also, both treated and untreated sisal/PVC composites

For other thermoplastics matrices, Manikandan et al.

have quite good moisture resistance.

[43] studied the tensile properties of short sisal-®bre-

reinforced polystyrene composites. Untreated and ben-

4.3. Sisal-®bre-reinforced rubber matrix

zoylated sisal ®bres were used to produce the compo-

sites and the in¯uences of ®bre length, ®bre content,

Table 8 shows that rubber is the second most widely

®bre orientation and ®bre benzoylation were investi-

used matrix for sisal ®bre composites behind poly-

ethylene [53±59]. Rubber matrices include natural rub-

Variation in ®bre length produces no considerable

ber and styrene±butadiene rubber. The main research

change in the modulus of the composites but gives

areas concern the eect of ®bre length, orientation,

maximum tensile strength (25 MPa) at a ®bre length of

loading, type of bonding agent and ®bre/matrix inter-

about 10 mm (aspect ratio=82). This critical ®bre

action on the properties of the composites which include

length is quite dierent to the sisal/PE composite which

mechanical properties, rheological behaviour, thermal

is 6 mm. Table 11 shows the eect of ®bre-volume frac-

ageing, gamma-radiation and ozone resistance.

tion on the mechanical properties. There is an initial

Experimental results show that, for best balance of

reduction in tensile strength at Vf 10% followed by

properties, the ®bre length is about 6 mm. This is the

an increase to Vf 20% and remains constant at even

same as the sisal/PE composites. Orientation eects are

higher Vf. These results are also dierent to sisal/PE

as expected. Addition of short sisal ®bres to rubber oers

composites which conform to the rule of mixtures. The

good reinforcement, which can be further strengthened

orientation eects on the mechanical properties of sisal/

by a suitable coupling agent such as a resorcinol/heca

PS composites are also given in Table 11.

bonding system.

A two-stage stress relaxation has been observed in

4.2.4. Properties of sisal-®bre-reinforced PVC composite

acetylated sisal-®bre-reinforced natural rubber compo-

Yang et al. [42] studied sisal/PVC composites with

sites. Initial relaxation occurs at short times (200 s), and

respect to the eects of ®bre and matrix modi®cation,

second-stage relaxation takes much longer to complete.

processing parameters on the mechanical and water

The initial mechanism is a result of the ®bre/rubber

resistance properties. Their main objective is to obtain

attachments and the latter to the physical and chemical

the best processing parameters and interface modi®ca-

relaxation processes of the natural rubber molecules.

tion to make novel sisal/PVC composites. To make good

The relaxation is in¯uenced by the coupling agent indi-

use of sisal ®bre and PVC, it is important to improve the

cating that the ®bre/rubber interface is involved. Gum

interface so that better mechanical properties of the

vulcanite shows only one relaxation process, the rate of

composite can be obtained. But, unfortunately,their

which is almost independent of the strain level. For the

results show that thermal treatment, acetylation and

composite without a coupling agent, the rate of relaxa-

coupling agent improve neither the interface nor the

tion increases with strain level and vice versa. The initial

mechanical properties. On the contrary, the untreated

rate of the stress-relaxation process diminishes after

sisal-®bre-reinforced PVC composite possesses better

ageing (at 70 and 100�C for 4 days).

mechanical properties. These results have been explained

Varghese et al. [57] studied the eect of acetylation

by the small ®bre-volume fraction (18.5%) of their

and bonding agent on the ageing properties of sisal-®bre-

composites and the melting processing method that

reinforced natural rubber composites which include

Tensile properties of sisal-polystyrene composites as a function of ®bre content and ®bre orientation [43]a

Fibre Content (wt%)

Ultimate tensile strength (MPa)

Young's modulus (MPa)

Elongation at break (%)

a Fibre length was 6 mm. The values in parentheses give the properties of untreated ®bre composites. L, longitudinal; T, transverse; R, randomly

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

thermal ageing, gamma radiation and ozone resistance.

®re behaviour of sisal short-®bre-reinforced gypsum

High ®bre-volume fraction shows better resistance to

using specially designed testing equipment. Though

ageing, especially with ®bre-surface treatment. Fibre

gypsum itself has good combustion-resistance, with

orientation is also found to reduce the extent of degra-

increasing water reduction as a result of increasing

dation under these ageing conditions. Increasing the

temperature, there is a progressive shrinkage process

dosage of gamma radiation was found to increase the

that promotes surface ®ssuration. Adding sisal ®bres

extent of the ageing process.

into the gypsum matrix increases the ®re insulating per-

formance and delays the occurrence of surface ®ssura-

4.4. Sisal-®bre-reinforced gypsum and cement matrices

Swift [66] studied sisal/cement composites and their

For applications as building materials, sisal-®bre-

potential for rural Africa. He studied the mechanical

reinforced gypsum and cement composites have long

properties including ¯exural, energy absorption and

been studied before 1994 [60±65]. The majority of these

pointed out that a composite material formed by sisal

works are focused on interface, mechanical, ®re and

®bre and cement is suitable for applications in several

environmental properties and their applications.

structures. For example, cladding walls to produce

Bessell and Mutuli [65] studied the interfacial bond

earthquake-resistant adobe structures for houses, roof-

strength of sisal/cement composites using a tensile spe-

ing sheets and tiles, grain storage bins and water ducts.

cimen containing a single ®lament in the brittle matrix.

The crack spacing in the matrix was measured and used

4.5. Other matrix systems

to evaluate the ®bre/matrix bonding strength. It is

shown that the interfacial bond of sisal/cement compo-

Bisanda and Ansell [3] used cashew nut shell liquid

site is lower than that of other composites because sisal

(CNSL) as a matrix to make sisal-®bre-reinforced com-

®bre absorbs moisture from cement thus leading to a

posites. CNSL is a natural monomer blend that has

very poor interface.

been condensation polymerized with formaldehyde

The following aspects of sisal-®bre-reinforced cement

in the presence of an alkaline catalyst to produce a

or gypsum composites have also been studied pre-

thermosetting resin. It can be used to bind sisal ®bres to

viously. For example, Hernandez et al. [61] studied the

produce a cheap and useful composite. The resin is

Variation of mechanical properties with volume fraction of GRP in sisal/glass hybrid composites [68]ab

Volume fraction of ®bres

Elongation at break

a SRP, sisal-®bre-reinforced plastics; GRP, glass-®bre-reinforced plastics.

b Values in parentheses are properties of randomly oriented composites.

Properties of 50:50 sisal/glass hybrid composites containing alkali-treated and untreated sisal ®bre [68]a

Tensile strength (MPa)

Young's modulus (MPa)

Elongation at break (%)

Tear strength (N/mm) Hardness (Shore D)

a L, longitudinal oriented; R, random oriented.

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

thermally stable up to 230�C and is further cross-linked

when exposed to simulated sunlight. The plain woven

mats of mercerized sisal ®bre when impregnated with

Sisal ®bre is an eective reinforcement of polymer,

CNSL/fomaldehyde resin produced plain and corru-

rubber, gypsum and cement matrices. This has created a

gated laminated composites showing mean tensile

range of technological applications beyond its tradi-

strength of 94.5 MPa and Young's modulus of 8.8 GPa

tional usage as ropes, carpets, mats, etc.

[3]. It is recommended that these low-cost corrugated

The mechanical and physical properties of sisal ®bre

panels can be used for roo®ng applications as a

not only depend on its source, position and age which

result of their adequate crush bending strength (13.9

will aect the structure and properties, but also depend

on the experimental conditions, such as ®bre diameter,

gauge length, strain rate and test temperature.

Fibre-surface treatment can improve the adhesion

5. Sisal and synthetic hybrid-®bre composites

properties between sisal ®bre and matrix and simulta-

neously reduce water absorption. Such methods include:

Reinforcement by two or more ®bres in a single

(a) silane and other coupling agents to introduce long

matrix leads to hybrid composites with a great diversity

chain structures onto the sisal ®bre to change its

of material properties. It appears that the behaviour of

hydrophilic characteristics; (b) peroxide to promote

hybrid composites is simply a weighted sum of the indi-

grafting reactions; (c) permanganate and alkali to

vidual components so that there is a more favourable

increase the roughness of ®bre surface hence increasing

balance of properties in the resultant composite mate-

the surface area available for contact with the matrix;

rial. Sisal and glass ®bres are one good example of

and (d) thermal treatment.

hybrid composites [67±69] possessing very good com-

Dierent matrix systems have dierent properties.

bined properties.

The mechanical and physical properties of sisal-®bre-

For sisal/glass-®bre-reinforced LDPE hybrid compo-

reinforced composites are very sensitive to processing

sites, the eects of ®bre orientation, composition and

methods, ®bre length, ®bre orientation and ®bre-volume

®bre-surface treatment on the mechanical properties

have been studied and the results are shown in Table 12.

Sisal and glass ®bres can be combined to produce

Owing to the superior properties of glass ®bres the

hybrid composites which take full advantage of the best

mechanical properties of the hybrid composites increase

properties of the constituents. Almost all the mechanical

with increasing volume fraction of glass ®bres. Positive'

properties show positive' hybrid eects.

or negative' hybrid eect is de®ned as larger' or smal-

ler' than the properties calculated from the rule of mix-

tures of the two constituent ®bre-reinforced composites.

A positive hybrid eect has been observed for all

mechanical properties except elongation at break. This

From this review, it is clear that chemically treated or

eect is a consequence of increased ®bre dispersion and

modi®ed sisal-®bre-reinforced composites are potential

orientation with increasing volume fraction of glass

structural materials as a result of their good mechanical,

environmental and economic properties. The following

The eect of chemical modi®cation (alkali treatment)

areas of research are, however, needed to realise wider

of sisal ®bres on the mechanical properties of a 50:50

applications of sisal ®bres in engineering:

sisal/glass hybrid composite is shown in Table 13 and

the improvement is generally less than 10%. Water

absorption of the composite is reduced from 11.6 to

. Sisal-textile-reinforced composite is an important

3.1% compared to the non-hybridized sisal-®bre com-

area in which little work has been done [3]. Sisal

®bres can be woven into textile preforms and

Yang et al. [69] studied the mechanical and interface

impregnated with resins by resin transfer moulding

properties of sisal/glass-®bre-reinforced PVC hybrid

(RTM) or resin ®lm infusion (RFI) to make

composites before and after immersion in water. It is

superior but more economical composites.

found that there exists a positive' hybrid eect for the

. Microstructure of the interface between sisal ®bre

¯exural modulus and unnotched impact strength but a

and matrix still needs to be investigated and the

negative' hybrid eect for the ¯exural strength. It is

interfacial properties should be studied with more

suggested that the negative' hybrid eect is caused by

rigorous single ®bre pullout and fragmentation

the poor interface between sisal, glass ®bres and PVC

tests [70]. The relationship between interface and

matrix. They also suggested that water will have a det-

bulk composite properties should be established.

rimental eect on the ®bre/matrix interface leading to

. Fracture toughness and fracture mechanisms of

reduced properties.

sisal-®bre composites do not seem to have been

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

studied in any depth in previous published works.

on the tensile properties of short sisal ®bre-reinforced poly-

This is important if new improved materials are to

ethylene composites. Polymer 1996;37:5139±49.

be developed for safe usage against crack growth.

[7] Chand N, Hashmi SAR. Metals Materials and Processes

. Mechanical properties of sisal-®bre composites

[8] Bisanda ETN, Ansell MP. The eect of silane treatment on the

measured from tests quite often disagree with the

mechanical and physical properties of sisal±epoxy composites.

rule of mixtures. A full explanation can only be

Composites Science and Technology 1991;41:165±78.

obtained if the interface strength and the failure

[9] Li H, Zadorecki P, Flodin P. Cellulose ®bre±polyester composites

mechanisms are known. Further work is needed

with reduced water sensitivity. (1) Chemical treatment and

particularly to explain hybrid' eects in sisal/glass

mechanical properties. Polymer Composites 1987;8:199±207.

[10] Chand N, Sood S, Rohatgi PK, Sayanarayana KG. Resources,

structure, properties and uses of natural ®bres of madhya pra-

. Economical processing methods must be devel-

desh. Journal of Scienti®c and Industrial Research 1984;43:489±

oped for the composites because of the very low

price of sisal ®bres. The relationship between

[11] Bisanda ETN. The manufacture of roo®ng panels from sisal ®bre

mechanical properties and processing methods

reinforced composites. Journal of Materials Processing Technol-

should be established.

[12] Chand N, Satyanarayana KG, Rohatgi PK. Mechanical char-

. New applications should be found for sisal-®bre-

acteristics of sunhemp ®bres. Indian Journal of Textile Research

based composites. Hybrid ®bre composites with

sisal and other ®bres rather than glass may open

[13] Hornsby PR, Hinrichsen E, Tarverdi K. Preparation and prop-

up new applications. For example, from the eco-

erties of polypropylene composites reinforced with wheat and ¯ax

straw ®bres. Part 1, ®bre characterisation. Journal of Materials

nomics point of view, sisal ®bres may be hybri-

dised with carbon or aramid ®bres to reduce the

[14] Satyanarayana KG, Sukumaran K, Mukherjee PS, Pavithran C,

costs of these expensive ®bres reinforced compo-

Pillai SG. Natural ®bre-polymer composites. Cement & Concrete

sites whilst maintaining their good mechanical

[15] Chand N, Hashmi SAR. Mechanical properties of sisal ®bre at

. Recycling (including burning) characteristics and

methods of sisal-®bre-reinforced composites are

[16] Chand N, Joshi SK. Temperature dependence of dielectric beha-

important aspects of this new material but there

viour of sisal ®bre. Journal of Materials Science Letters

are very few published data to date. Recycling is

an attractive future research direction that will

[17] Yang GC, Zeng HM, Zhang WB. Thermal treatment and ther-

mal behaviour of sisal ®bre. Cellulose Science and Technology

provide socio-economic bene®ts.

[18] Zhou LM, Mai Y-W, Ye L, Kim JK. Techniques for evaluating

interfacial properties of ®bre-matrix composites. Key Engineering

[19] Kim JK, Zhou LM, Mai Y-W. Interfacial debonding and ®bre

pull-out stresses. Part III. Interfacial properties of cement matrix

Y. Li would like to thank the University of Sydney

composites. Journal of Materials Science 1993;28:3923±30.

for an Overseas Postgraduate Research Scholarship

[20] Yang GC, Zeng HM, Li JJ, Jian NB, Zhang WB. Relation of

(OPRS) and an International Postgraduate Award

modi®cation and tensile properties of sisal ®bre. Acta Scien-

(IPA). Y.-W. Mai also thanks the Australian Research

tiarum Naturalium Universitatis Sunyatseni 1996;35:53±7.

Council for the continuing support on the ®bre/matrix

[21] El-Naggar AM, El-Hosamy MB, Zahran AH, Zondy MH. Sur-

face morphology/mechanical/dyeability properties of radiation-

interface research project.

grafted sisal ®bres. American Dyestu Reporter 1992;81:40±4.

[22] Sabaa MW. Thermal degradation behaviour of sisal ®bres graf-

ted with various vinyl monomers. Polymer Degradation & Stabi-

[23] Chand N, Verma S, Khazanchi AC. SEM and strength char-

[1] Murherjee PS, Satyanarayana KG. Structure and properties of

acteristics of acetylated sisal ®bre. Journal of Materials Science

some vegetable ®bres, part 1. Sisal ®bre. Journal of Materials

[24] Singh B, Gupta M, Verma A. In¯uence of ®bre surface treatment

[2] Chand N, Tiwary RK, Rohatgi PK. Bibliography resource

on the properties of sisal±polyester composites. Polymer Com-

structure properties of natural cellulosic ®bres Ð an annotated

bibliography. Journal of Materials Science 1988;23:381±7.

[25] Kim JK, Lu S, Mai Y-W. Interfacial debonding and ®bre pull-

[3] Bisanda ETN, Ansell MP. Properties of sisal±CNSL composites.

out stresses Part IV: In¯uence of interface layer on the stress

Journal of Materials Science 1992;27:1690±700.

transfer. Journal of Materials Science 1994;29:554±61.

[4] Wilson PI. Sisal, vol. II. In Hard ®bres research series, no. 8,

[26] Yang GC, Zeng HM, Li JJ. Study of sisal ®bre/phenol for-

Rome: FAO, 1971.

maldehyde resin composites. Fibre Reinforced Plastics/Compo-

[5] Rowell RM. In: Rowell RM, Schultz TP, Narayan R, editors.

Emerging technologies for materials & chemicals for biomass,

[27] Sanadi AR, Prasad SV, Rohatgi PK. Sunhemp ®bre-reinforced

ACS Symposium Ser, 476, 1992. p. 12.

polyester Part 1 Analysis of tensile and impact properties. Jour-

[6] Joseph K, Thomas S, Pavithran C. Eect of chemical treatment

nal of Materials Science 1986;21:4299±304.

[28] Pavithran C, Mukherjee PS, Brahmakumar M, Damodaran AD.

Y. Li et al. / Composites Science and Technology 60 (2000) 2037±2055

Impact properties of natural ®bre composites. Journal of Mate-

[48] Nielson LE. Mechanical properties of polymers and composites,

rials Science Letters 1987;6:882±4.

vol. 2. New York: Marcel Dekker, 1974.

[29] White NM, Ansell MP. Straw-reinforced polyester composites.

[49] Cox HL. The elasticity and strength of paper and other ®brous

Journal of Materials Science 1983;18:1549±56.

materials. British Journal of Applied Physics 1952;3:72±9.

[30] Pavithran C, Mukherjee PS, Brahmakumar M, Damodaran AD.

[50] Bowyer WH, Bader MG. On the re-enforcement of thermo-

Impact performance of sisal±polyester composites. Journal of

plastics by imperfectly aligned discontinuous ®bres. Journal of

Materials Science Letters 1988;7:825±6.

Materials Science 1972;7:1315±21.

[31] Gordon JE, Jeronimidis. Philosophical Transactions. Royal

[51] Paul A, Thomas S, Pavithran C. Electrical properties of natural-

Society of London, Series A: Mathematical and Physical Sciences

®ber reinforced low density polyethylene composites: a compar-

ison with carbon black and glass-®bre ®lled low density poly-

[32] Rong MZ, Li RKY, Ng CN, Tjong SC, Mai Y-W, Zeng HM.

ethylene composites. Journal of Applied Polymer Science 1997;

Eect of ®bre pretreatment on the impact fracture toughness of

sisal ®bre reinforced polymer composites. In Proc. First Asian±

[52] Joseph K, Thomas S, Pavithran C. Eect of ageing on the physi-

Australian Conference on Composite Materials (ACCM- 1), 7±9

cal and mechanical properties of sisal-®bre-reinforced poly-

October 1998, Oseka, Japan. p 433-1±4.

ethylene composites. Composites Science and Technology

[33] Rong MZ, Li RKY, Ng CN, Tjong SC, Mai Y-W, Zeng HM.

Eect of water absorption on the impact behaviour of short sisal

[53] Prasantha RP, Kumar ML, Amma G, Thomas S. Short sisal ®bre

®bre reinforced polymer composites. In Proc. First Asian±Aus-

reinforced styrene±butadiene rubber composites. Journal of

tralian Conference on Composite Materials (ACCM-1), 7±9

Applied Polymer Science 1995;58:597±612.

October 1998, Oseka, Japan. p 438-1±4.

[54] Varghese S, Kuriakose B, Thomas S. Stress relaxation in short

[34] Joseph K, Thomas S, Pavithran C. Dynamic mechanical proper-

sisal-®bre-reinforced natural rubber composites. Journal of

ties of short sisal ®bre reinforced low density polyethylene com-

Applied Polymer Science 1994;53:1051±60.

posites. Journal of Reinforced Plastics and Composites

[55] Kumar RP, Thomas S. Short ®bre elastomer composites: eect of

®bre length, orientation, loading and bonding agent. Bulletin of

[35] Joseph K, Thomas S, Pavithran C, Brahmakumar M. Tensile

Materials Science 1995;18:1021±9.

properties of short sisal ®bre-reinforced polyethylene composites.

[56] Kumar PR, Thomas S. Tear and processing behaviour of short

Journal of Applied Polymer Science 1993;47:1731±9.

sisal ®bre reinforced styrene butadiene rubber composites. Poly-

[36] Joseph K, Kuriakose B, Premalatha CK, Thomas S. Melt rheo-

mer International 1995;38:173±82.

logical behaviour of short sisal ®bre reinforced polyethylene

[57] Varghese S, Kuriakose B, Thomas S. Short sisal ®bre reinforced

composites. Plastics Rubber & Composites Processing & Appli-

natural rubber composites: high-energy radiation, thermal and

ozone degradation. Polymer Degradation & Stability 1994;44:55±

[37] Joseph K, Thomas S, Pavithran C. Viscoelastic properties of

short-sisal-®bre-®lled low-density polyethylene composites: eect

[58] Varghese S, Kuriakose B, Thomas S, Koshy AT. Mechanical and

of ®bre length and orientation. Materials Letters 1992;15:224±8.

viscoelastic properties of short ®bre reinforced natural rubber

[38] Karmaker AC. Eect of water absorption on dimensional stabi-

composites: eects of interfacial adhesion, ®bre loading, and

lity and impact energy of jute ®bre reinforced polypropylene.

orientation. Journal of Adhesion Science & Technology 1994;

Journal of Materials Science Letter 1997;16:462±4.

[39] Garkhail S, Heijenrath R, Oever M, van den, Bos H, Peijs T.

[59] Varghese S, Kuriakose B, Thomas S, Premalatha CK. Rheologi-

Natural-®bre-mat-reinforced thermoplastic composites based on

cal behaviour of short sisal ®bre reinforced natural rubber com-

¯ax ®bres and polypropylene. In Scott M, editor. Proceedings of

posites. Plastics Rubber & Composites Processing & Applications

ICCM-11, vol. II, Fatigue, fracture and ceramic matrix compo-

sites, Gold Coast, Australia, 14±18 July 1997. p. 794±803.

[60] Singh M, Garg M. Gypsum-based ®bre-reinforced composites:

[40] Park BD, Balatinecz JJ. Eect of impact modi®cation on the

an alternative to timber. Construction & Building Materials

mechanical properties of wood-®bre thermoplastic composites

with high impact polypropylene (HIPP). Journal of Thermo-

[61] Hernandez OF, Oteiza IDe, Villanueva L. Fire behaviour of sisal

plastic Composite Materials 1996;9:342±63.

short ®bres reinforced gypsum. In Miraveter A, editor. Proceed-

[41] Hornsby PR, Hinrichsen E, Tarverdi K. Preparation and prop-