Control over large-volume changes of lithium battery anodes via active–inactive metal alloy embedded in porous carbon

Available online at www.sciencedirect.com

RAPID COMMUNICATION

Control over large-volume changes of lithiumbattery anodes via active–inactive metal alloyembedded in porous carbon

Nasir MahmoodJinghan Sarish Rehman, Quan LiYanglong Hou

aDepartment of Materials Science and Engineering, College of Engineering, Peking University,Beijing 100871, ChinabDepartment of Physics, The Chinese University of Hong Kong, Shatin, New Territory, Hong Kong, China

Received 14 February 2015; received in revised form 26 May 2015; accepted 29 May 2015

Available online 6 June 2015

Lithium ion battery;

Large volume changes and limited access to redox sites of high capacity anode materials are great

challenges. Although, various strategies were adopted but still results are far from required values for

Long cyclic life;

their practical usage. Here, we have designed a unique structure to prevent surface reaction and

structural disintegration meanwhile intrinsic conductivity is improved to involve all redox sites in

conversion reaction. CoSn

x@C–PAn hybrid was synthesized through aqueous chemical route, Co doping

in tin make accessible all redox sites by faster conduction of electrons while its hard nature relaxesinternal stress, carbon shell prevents surface reaction and brings well control on solid electrolyteinterface (SEI) film by maintaining barrier between electrode surface and electrolyte and nitrogendoped porous carbon provides faster diffusion of Li+ deep in electrode make possible high massloadings and conduction highway for electrons. Furthermore, porous carbon also provides room tocompensate volume expansion and keeps electrode structure stable. Because of its unique structurehybrid shows excellent reversible capacity of 2044 mAh/g (retention 100%) with mass loading of3.8 mg/cm2 along with long cyclic life up to 1000 cycles and bears high rate capability (20 A/g).Webelieve that present study makes possible the use of high capacity materials in applications.

& 2015 Elsevier Ltd. All rights reserved.

Presently, lithium ion batteries (LIBs) have got tremendousattention due to their high energy densities and have beenconsidered as promising power source for future electric

E-mail address: . Hou).

N. Mahmood et al.

vehicles (EV) Therefore, in order to achieve the

carbon (N-PGC) matrix named as CoSnx@C–PAn is developed

practical applications of LIBs in EVs, there are numerous

via in-situ polymerization and annealing processes. This

efforts on seeking for high performance anode materials that

nanostructure has multiple advantages: (1) doping of elec-

possess high capacity and excellent stability with long cyclic

trochemically inactive Co prevents structural changes and

life . Metallic tin (Sn) is considered as a potential

enhances internal conductivity of Sn to involve all redox

substitute for conventional graphite anode (372 mAh/g) due

sites in conversion reaction. (2) The nanosized particles can

to its high theoretical capacity (992 mAh/g) and thermal

accommodate large volume strains, hard Co improves CRt

stability . However, structural disintegration, larger

and electrochemical active Sn brings about high capacity.

diffusion barrier, limited access to redox sites and loss of

(3) The mixed phase provides large grain boundary densities

electrical contact have long been identified as primary

for enhanced interfacial Li + storage, channels for faster Li +

reasons for capacity loss and poor cyclic life of Sn-based

diffusion by reducing the diffusion path below 10 nm.

anodes . Although nanochemistry plays a critical role

(4) Carbon shell completely encapsulates nanoparticles

to accommodate volume strains by developing nanosized

(NPs) and thus prevents surface reactions by controlling

structures of Sn, their use is still limited by unstable solid

direct contact with electrolyte and limit SEI on outer side

electrolyte interface (SEI) layer on the surface and poor

with controlled thickness. (5) The carbon framework pro-

internal conductivity As the organic electrolytes

vides faster transport highways for electrons and Li + via

decompose at the working potential of o0.5 V vs. Li+/Li and

pore walls and pores, respectively. (6) High surface area and

forms a thin SEI layer . But the expansion and

well-defined pore size distribution improves the active

contraction of Sn during alloying and de-alloying causes

surface area of the hybrid minimizing percentage of inactive

deformation and breakage of the SEI layer, respectively

material through deep transport of electrolyte and make

. As a result, formation of new SEI on freshly

possible high mass loadings. (7) The existence of large

exposed Sn surface eventually block Li+ transport via accu-

nitrogen contents and graphitic ring (make possible Li6/C6

mulation within SEI and causes poor Coulombic efficiency (CE)

conversion reaction) improve the overall conductivity and

of cell As a consequence, the capacity decays as SEI

electrochemical activity of hybrid to bring high perfor-

thickness increases while most of Sn active material remains

mance. With such a rational design, CoSnx@C–PAn hybrid

electrically connected . However, nanosized designing has

shows excellent discharge capacity of 2044 mAh/g with

improved the cyclic life with enhanced performance but

extraordinary CE and CRt of �100% after 100 cycles at

simple reduction of crystallite size to nanoscale has intro-

0.2 A/g with mass loading of 3.8 mg/cm2. Furthermore,

duced new fundamental challenges . Large surface

hybrid was tested at current density of 10 A/g for 1000

area exposed to electrolyte and higher surface energy that

cycles to explore the stability for long cyclic life and rate

increase side reactions, results in lower CE and causes

capability at higher charge–discharge rates (20 A/g), inter-

thermal runway which leads to internal short circuit due to

estingly, hybrid shows excellent capacity (1256 mAh/g) with

melting of separator –. Furthermore, low tap density

high CE and CRt (�100%) after 1000th cycle at current

increases thickness of electrode at high mass loading and

density of 10 A/g. It is believed that the presented design

leads to low volumetric capacity by increasing Li+ transfer

will be very helpful to overcome the large-volume changes

pathway . Generally, poor electrical properties are

in electrode materials for energy storage devices with much

observed due to higher inter-particle resistance which is

improved capacity values.

further dominated by volume changes during charging–dis-charging, affecting cyclic life of electrode drastically A

Experimental section

lot of efforts have been devoted by developing electrolyteblockage layers, creating void space via void engineering and

The synthesis of Sn, Sn@C, PAn, N-PGC and characterization

making their composites with elastically strong graphene and

part are provided in supporting information.

inactive hard metals to sustain the structure and improve thecyclic life of Sn-based electrodes However, to the

best of our knowledge, stability concerns for long cyclic life

2SnO4 nanoparticles

and high performance with good CE and capacity retention(CR

t) at higher mass loadings (43 mg/cm2) has not been

reported yet for Sn-based materials. To achieve this, a careful

(176 mg), CoCl2 � 6H2O (238 mg) and CTAB (400 mg) are

design of electrode materials, is highly required, that main-

mixed in 20 mL of water and stirred with heating unless

tains faster and deep transfer of Li+, provides better pathway

temperature reaches to 85 1C. Subsequently, 20 ml of 4 M

for electron and ions movement, prevents surface reactions

NaOH solution was added and the mixture was stirred for

with electrolyte and keeps the structural integrity of elec-

60 min at 85 1C. After the completion of reaction, the

trode . Furthermore, Han et al. also investigated theore-

product was collected by centrifugation and washed six

tically that fused graphitic C

times with water and ethanol, repeatedly. Finally, the solid

6 can deliver 42000 mAh/g via

accumulation of Li+ through reversible reaction Li

product was dried at 70 1C for 6 h in a vacuum oven.

Thus, utilizing the above design with conductive networkcontaining fused C

6 backbone can bring higher capacity.

2SnO4–PAn hybrid

Here, we present an architectured design to overcome

the aforementioned problems associated with Sn-based

Co2SnO4–PAn hybrid was synthesized via in-situ polymeriza-

electrodes to bring high performance with longevity at

tion of aniline monomers with Co2SnO4 NPs. Initially 50 mg

low cost. An active–inactive metal alloy sealed in carbon

of aniline monomers was stirred for 5 min in water and pH of

shell and embedded in nitrogen-doped porous graphitic

the solution was turned acidic using HCl. Afterward, the

Control over large-volume changes

50 mg of NPs was added and the reaction mixture was

electrochemical properties of Sn. Furthermore, the lithium

stirred further for 10 min. Finally, the addition of APS

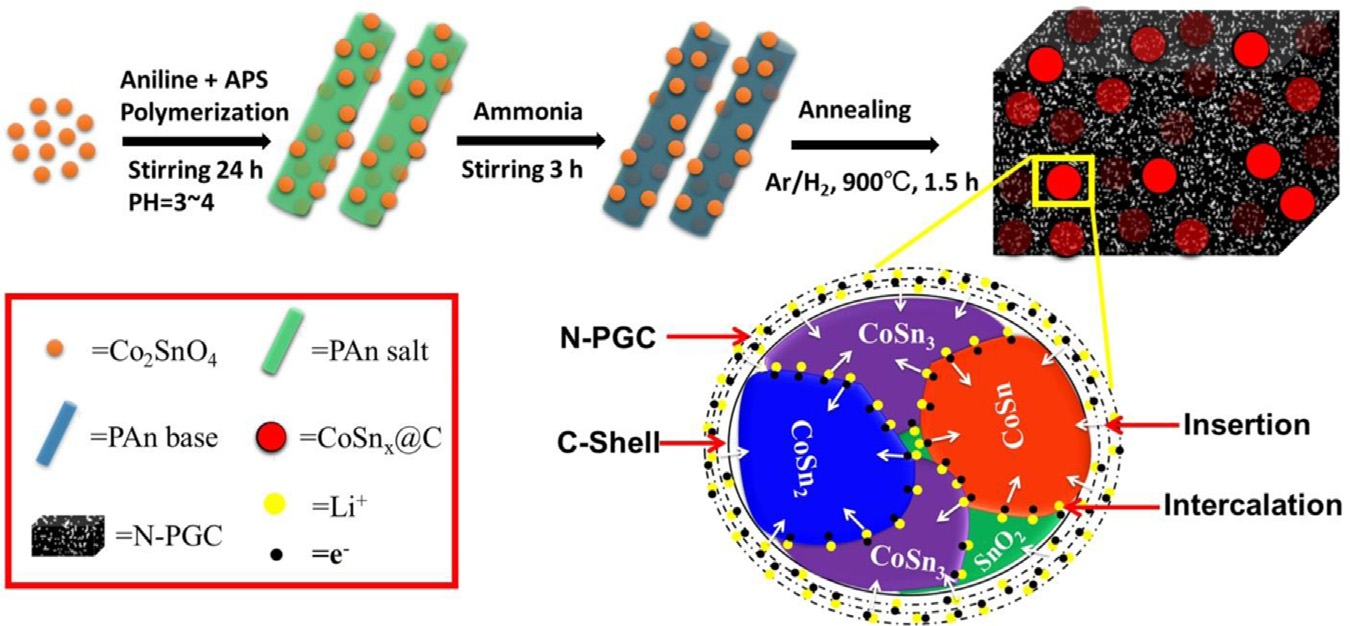

storage mechanism is also illustrated in as shown in

(114 mg) as oxidant was done and reaction mixture was

that lithium can be stored through intercalation

stirred for 24 h. After the completion of polymerization

chemistry both in the carbon matrix via Lix/C6 (X=1–6)

addition of ammonia solution was carried out and stirred for

conversion reaction and can contribute capacity up to

further 3 h to turn the PAn salt (green) to PAn base (blue). At

2000 mAh/g depending on the number of lithium intercalated

last, the final product was centrifuge and wash 6 times with

and at Li+ storage at grain boundaries through space charge

water and ethanol repeatedly. The Final product was dried

layer. Further, the diffusion of Li+ becomes easier and faster

at 70 1C for 6 h under vacuum.

through the grain boundaries inside the NPs as shown by thearrows which results faster insertion and conversion reaction.

Synthesis of CoSn

In fact the porous carbon maintain the faster diffusion outside

the NPs and grain boundaries maintain faster diffusion insidethe NPs as results higher rate capability achieved. Further,

CoSnx@C–PAn hybrid was prepared by the thermal annealing

existence of Co inside maintain the continues flow of electron

process. Co2SnO4–PAn hybrid was annealed at 900 1C for

to redox sites and vice versa that utilizes all the redox centers

1.5 h with the heating rate of 2 1C/min under reducing

to bring higher performance, its hard nature prevents the

atmosphere of Ar/H2. Co2SnO4 NPs were also treated under

rapturing of carbon shell, as results direct contact of Sn with

the same condition to obtain CoSnx for comparative study.

electrolyte is inhibited and SEI film was blocked outside thecarbon coating around NPs. Further surface protection blocked

Results and discussion

the undesired side reaction to prevent the formation oflithium dendrites on surface and keep the entire structure

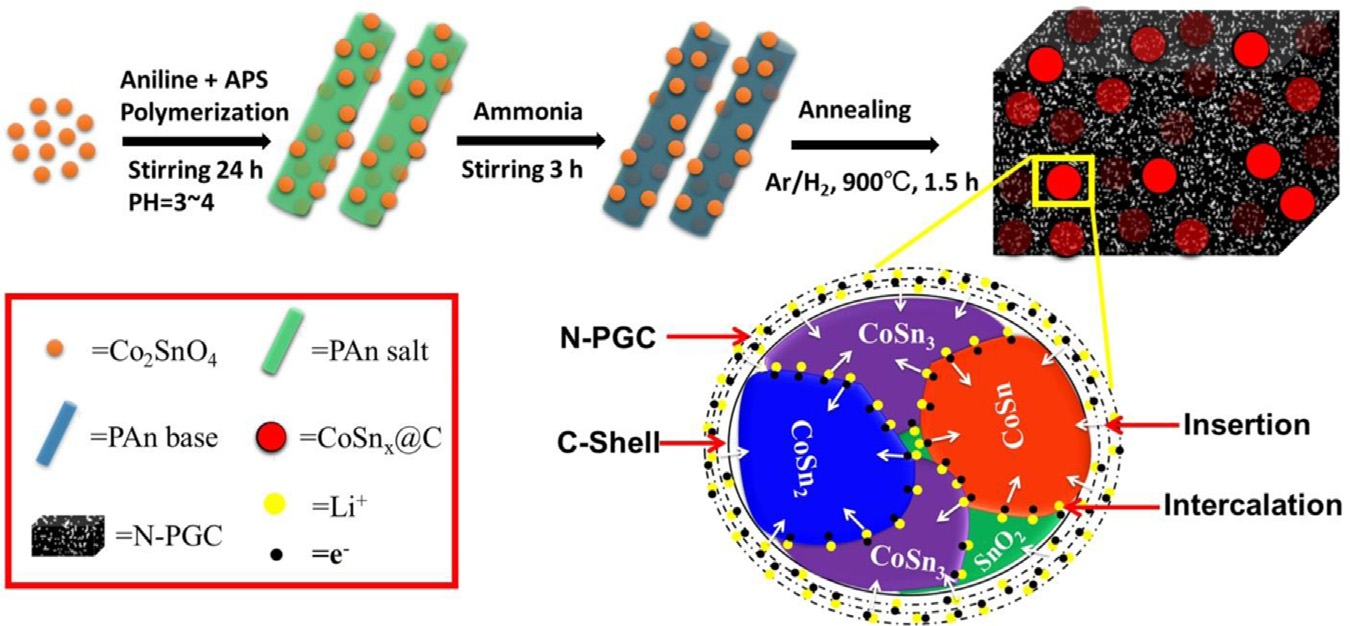

is presenting the synthesis strategy for CoSn

of electrode stable.

hybrid; first Co

To reveal the structure and composition of as-synthesized

2SnO4 NPs were synthesized via wet-chemistry

using co-precipitation of respective salts. Then via in-situ

CoSnx@C–PAn hybrid, the x-ray diffraction (XRD) analysis, x-

polymerization, NPs encapsulated polyaniline (PAn, green as

ray photoelectron spectroscopy (XPS), scanning transmission

emerladine salt) were grown in rod shape morphology which

electron microscope (STEM) and Raman spectroscopy were

were further converted to emerladine base (blue) using NH

carried out. a presents XRD patterns of Co

(the yield of hybrid can be easily increased or decreased by

Co2SnO4–PAn and CoSnx@C–PAn, from where it is observed

controlling the amount of aniline and NPs, without effecting

that Co2SnO4 NPs show their typical peaks well-matched with

electrochemical properties of hybrid). To obtain CoSn

standard card JCPDS no. 29-0514. An additional peak exist at

hybrid, the annealing process of Co

61.41 corresponds to the (220) plane of CoO (JCPDS no.48-

2SnO4–PAn hybrid was

performed at 900 1C for 90 min at a heating rate of 2 1C/min

1719). Interestingly, broad peaks were observed after PAn

under reducing atmosphere, which significantly reduce

grown on NPs due to its amorphous structure, as perceived

from XRD analysis of pure PAn shown in which

2SnO4 NPs to CoSnx alloy and build an uniform carbon shell

on the surface of CoSn

confirms complete encapsulation of NPs without aggrega-

NPs. Furthermore, N-PGC was

obtained from PAn via annealing, has high surface area and

tion. However, after annealing treatment, regular structure

well-defined micropores, additionally annealing effectively

of PAn was changed to porous graphitic carbon and well-

removed existing oxygenated groups that cause thick SEI layer

defined peaks of CoSnx were observed corresponding to

It is perceived that the nanoporous carbons obtained

three phases, CoSn2 (JCPDS no. 25-0256), CoSn (JCPDS no.

from the polymer via pyrolysis will form interconnected

02-0559) and CoSn3 (JCPDS no. 48-1813). Phase segregation

nanochannels and electronically conductive walls for both

of heterogeneous CoSn crystallites with multiple phases

transport, respectively. However, nanocrystals of

observed here is due to higher temperature synthesis

Sn and Sn@C were also synthesized to explore the effect of

It is worth noting that mixed phase has multiple

active–inactive metal alloy and porous carbon substrate on the

advantages over pure phase likewise, high grain boundary

Schematic illustration of synthesis method for CoSnx@C–PAn via in-situ polymerization and annealing processes; further

presenting the mechanism of lithium storage in the hybrid.

N. Mahmood et al.

(a) XRD patterns of Co2SnO4, Co2SnO4–PAn and CoSnx@C–PAn hybrids. (b) HAADF-STEM line profile analysis of CoSnx@C–PAn

hybrid. XPS spectrums of (c) CoSnx@C–PAn hybrid and (d) PAn. (e) BET nitrogen adsorption–desorption isotherm of CoSnx@C–PAn.

(f) Pore size distribution measured using BJH adsorption.

densities enhance the interfacial Li+ storage through space

well-defined reflection peaks exactly matched with

layer charge and thus offer large capacity and provide

JCPDS no. 04-0673, delineating pure phase of Sn NPs

channels for faster transport of Li+ in the NPs ,XRD

b and S5 show the elemental line profile and STEM

pattern of CoSnx@C–PAn also shows two diffraction peaks at

image of a CoSnx@C–PAn, respectively, line scan for bime-

26.61 and 51.71, attributed to (110) and (211) reflections of

tallic alloy was obtained with energy dispersive spectro-

SnO2, respectively (JCPDS no. 41-1445).

scopy (EDS) in high-angle annular dark field STEM (HAADF-

Raman spectrum of CoSnx@C–PAn shows typical D- and G-

STEM). The elemental distribution line for Sn (red) and Co

bands with ID/IG ratio 1.09 which confirms graphitic nature

(black) confirm that the alloy has a consistent chemical

of carbon matrix obtained from PAn ), a little

composition throughout the entire NP with higher concen-

higher intensity of D-band is attributed to the existence of

tration of Sn. Therefore, due to homogenous distribution

NPs . Furthermore, XRD pattern of PAn after annealing

cobalt can easily transfer electron from carbon shell to all

treatment verified the graphitic nature of extracted carbon

internal redox sites to carry on the conversion reaction and

as strong broad peak near 261 ) The

vice versa. Furthermore, faster transfer of electrons to

existence of C =C, C–N, C–H and NH2 was further confirmed

redox sites and accessibility of all redox sites through Co

by Fourier transform infrared (FTIR) spectroscopy, which

doping improved the CRt of the electrode even after long

emphasizes the graphitic nature of carbon with nitrogen

cyclic life. It is also expected that any strain generated by

doping . XRD pattern of Sn is shown in

Sn volume change during lithiation and de-lithiation should

Control over large-volume changes

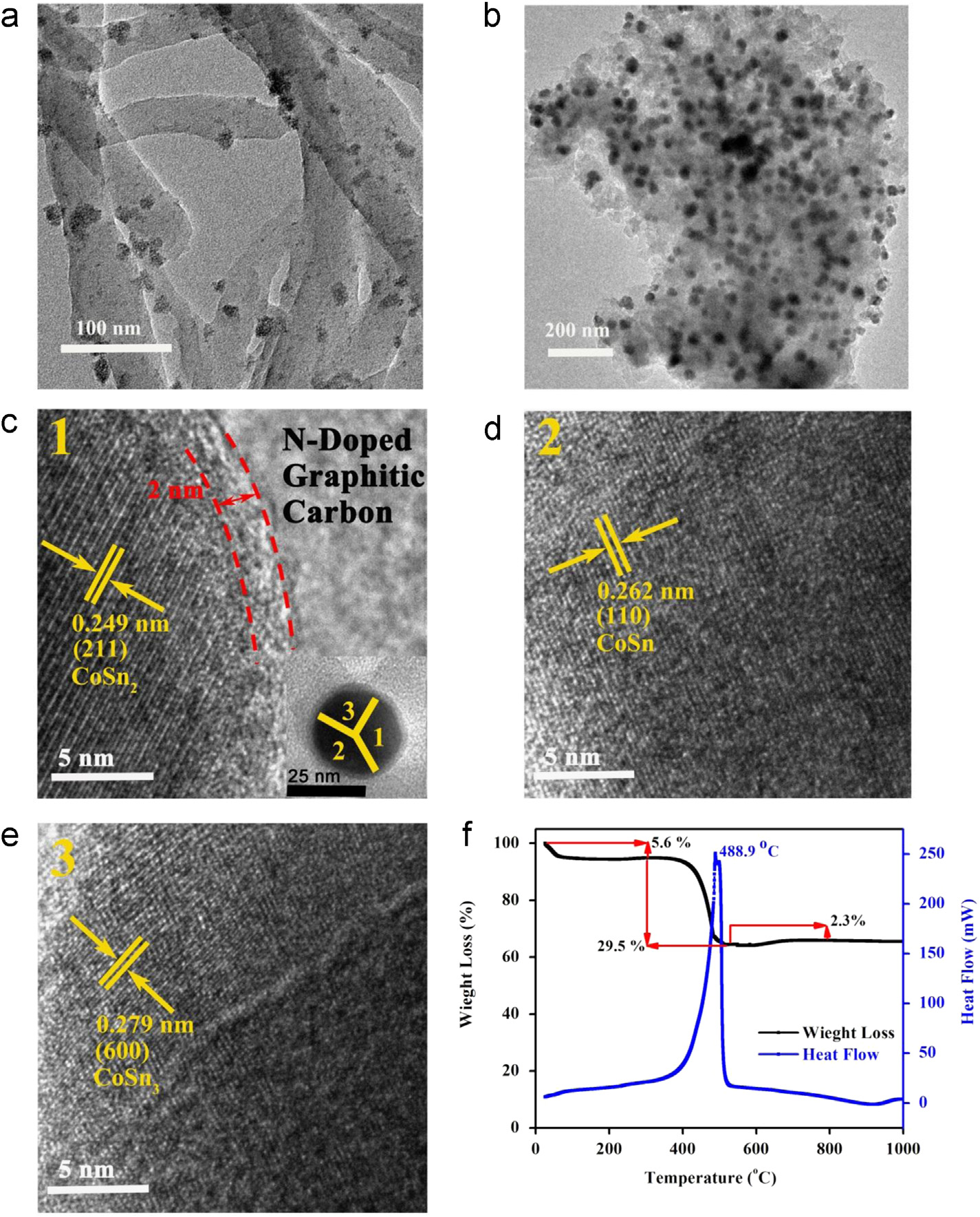

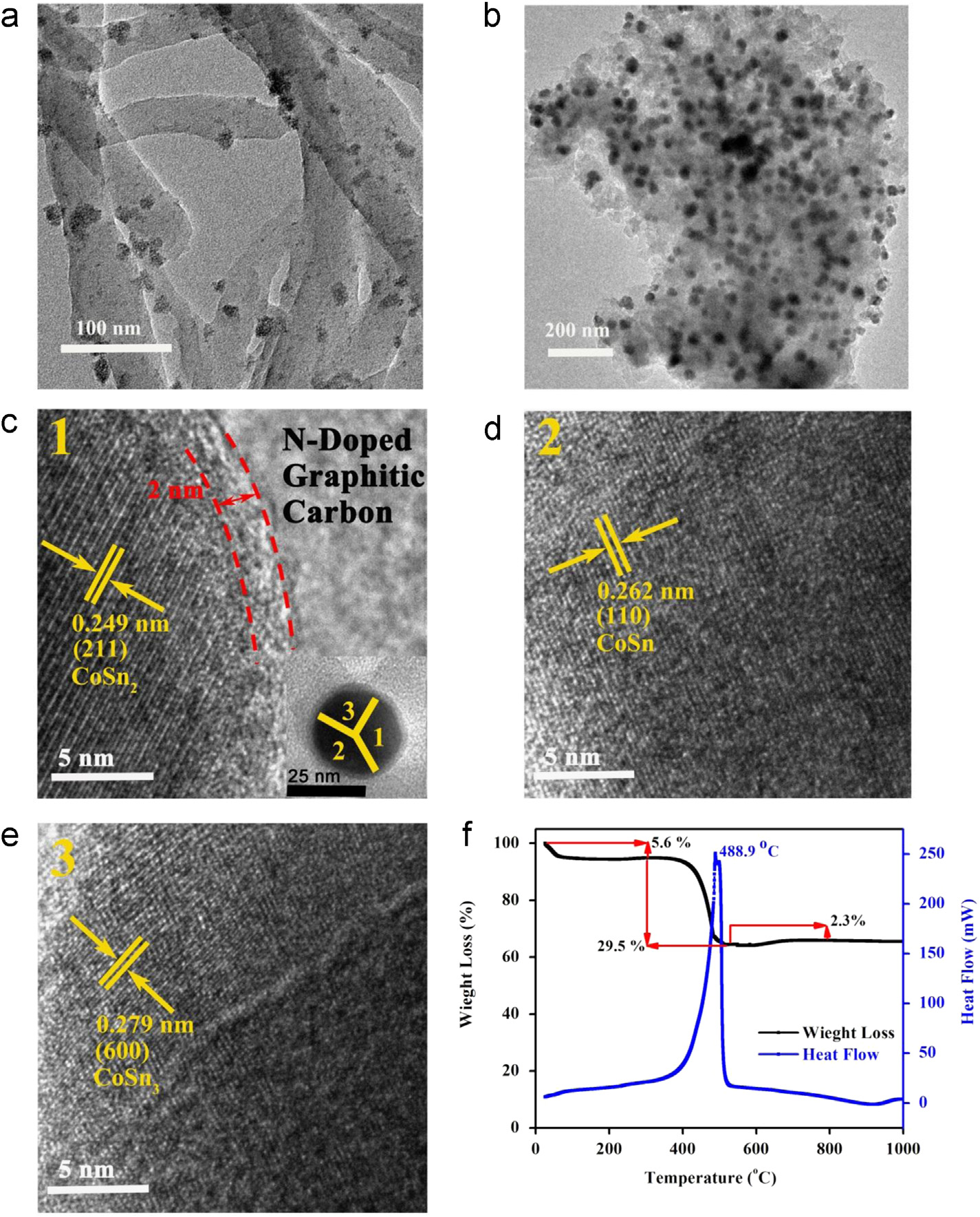

TEM images of (a) Co2SnO4–PAn hybrid and (b) CoSnx@C–PAn hybrid. (c) HRTEM image of the CoSnx@C–PAn hybrid at position

1 (the inset is enlarge image to show uniform carbon shell on NPs and position of HRTEM analysis), (d) HRTEM image of the CoSnx@C–PAn hybrid at position 2 and (e) HRTEM image of the CoSnx@C–PAn hybrid at position 3. (f) TGA/DSC curves of CoSnx@C–PAn hybrid.

be evenly distributed and compensated by hard counterpart

carbon, which is crucial for limiting the thickness of SEI

(Co). To further confirm the composition of CoSnx@C–PAn

layer on the outer surface of NPs via preventing the direct

hybrid, XPS studies were carried out for both hybrid and PAn

contact of NPs and electrolyte. Surface area and porosity

(and d), the peaks of core levels of Co, Sn, N and C

are important factors that are beneficial in electrochemical

confirms the presence of all chemical species. The concen-

energy storage especially batteries to improve the Li +

tration of each element calculated from XPS is 89.76%,

diffusion . However, fabrication of active nanomaterials

6.08%, 2.50%, 1.56% and 0.10% for C, O, N, Sn and Co,

with porous carbon substrate not only stabilizes structure of

respectively, as XPS is a surface detection technique thus

nanomaterials, but also provides electrical highway to

lower metallic contents were found because of surface

electrons via walls of pores as well as faster pathway to

coverage but still the concentration of Sn is higher than

ions through pores. Furthermore, nanoporosity results in

Co. The presence of little higher concentration of oxygen in

complete wetting of C6 fused aromatic carbon matrix to

CoSnx@C–PAn than PAn suggests that homogeneous precipi-

fulfill the desired conversion reaction of Li6/C6 to bring

tation of single phase CoSn is difficult due to existence of

maximum possible performance as discussed below .

oxidized metallic ions instead of pure metal, in accordance

In present study, PAn was converted to N-PGC by annealing

with XRD results. Further, high resolution Sn3d XPS spectrum

process without any acid or base treatment, and high

shows the existence of oxidized form of tin that is SnO2

surface area of 438.5 m2/g with well-defined pore size of

(Furthermore, the existence of large C peak in

�1–1.5 nm was obtained d and e). Homogeneous

XPS results further indicate complete coverage of NPs by

pore size distribution with high surface area provides

N. Mahmood et al.

efficient mass movement and larger space for Li+ storage as

advantages of higher grain boundary density and interfacial

well as relaxes the strains of NPs.

Li + storage at grain boundaries (called buried interfaces)

via space layer charge and brings additional capacity, the NP

Co2SnO4–PAn and CoSnx@C–PAn hybrids are presented in

is characterized by HRTEM at different positions as shown in

. The Co2SnO4 NPs are well-dispersed and embedded

the inset of c. The HRTEM analysis at position 2

in PAn rods without aggregation on surface (a).

(inset of c) shows the inter-planar distance of 0.262

Interestingly, it is found that if polymerizing reagent

nm, which corresponds to (110) plane of CoSn phase that is

(ammonium persulfate, APS) was added before the addition

in accordance with standard card (JCPDS No. 02-0559) as

of NPs, NPs only aggregate on the surface of PAn rods

shown in However, d-spacing of 0.279 nm is

(In fact, addition of APS start polymeriza-

calculated from the HRTEM analysis of position 3 (inset of

tion without NPs, but earlier addition of NPs causes poly-

which corresponds to (600) plane of CoSn3

merization on the surface of NPs in presence of hydrochloric

according to the standard card (JCPDS No. 48-1813) as

acid (HCl) which ionizes the aniline and increase its affinity

shown in Thus, HRTEM studies confirm the

towards NPs, resulting complete encapsulation of NPs and

proposed mechanism () of faster mass transfer

well-define morphology. It is worth noting that NPs are

via grain boundaries and larger Li + storage to bring higher

integrated as dimer or trimer in Co2SnO4–PAn hybrid as

capacity, long stable cyclic life and better rate capability.

compared to individual NPs These dimers and

The content of the metallic constituents (CoSnx) are

trimers fused during heat treatment, transforming into NPs

calculated to be 65% using thermal gravimetric analysis

with average size of 40 nm formed inside N-PGC (

(TGA) as carbon wipe-out at 488 1C through oxidation

the NPs size distribution is shown in The TEM

determined by differential scanning calorimetry (DSC,

image of CoSnx@C–PAn reveals that NPs are evenly distrib-

f). An increase in weight later near 700 1C is due

uted and well embedded in N-PGC matrix. Furthermore, it is

to the oxidation of metallic species. The TEM image of Sn

also perceived that N-PGC matrix has multidimensional

NPs (shows that NPs grew in the size of �20 nm

structure due to random stacking of PAn rods to facilitate

with well-defined structure confirmed through SAED (

the faster mass transportation and enhance the wettability

). A 2.2 nm thick carbon shell is also constructed on

of the C6 matrix. However, the presence of circular rings

pure Sn NPs (Sn@C, ) for the sake of

with bright spots in selected area electron diffraction

comparative electrochemical study with CoSnx@C–PAn.

(SAED) pattern of CoSnx@C–PAn clearly depicts the existence

The benefits of rational design of CoSnx@C–PAn for Li+

of CoSnx alloy in hybrid () and is in accordance

storage were investigated through electrochemical response

with the XRD results mentioned above. It is noted that the

of the obtained hybrid, by developing as anode in coin type

PAn grew in three dimensional networks ,

cell. The redox response of hybrid was delineated by cyclic

mechanism is discussed in supporting information

voltammetry (CV), scanned at 0.2 mV/s and cycled between

), which provides higher surface area to hybrid while PAn

0.005 and 3.0 V vs. Li+/Li a). CV curve shows the

keeps its multidimensional structure even after annealing

similar redox peaks for Sn reaction with Li+ to Li4.4Sn at 1.65

treatment at high temperature (). The aim of

and 0.85 V and extraction of lithium occurred at 0.27 V and

surface protection of NPs was achieved through in-situ

2.1 V during cathodic and anodic sweep, respectively. The

polymerization of aniline monomers on the surface of NPs

peak appear near 0.5 V during cathodic scan corresponds to

rather than construction of simple conduction highway for

the breakdown of electrolyte to form SEI film but no peak

ions and electrons. It is found that during heat treatment

observed in the successive cycles that confirm high reversi-

the aniline attached on NPs surface shaped a uniform shell

bility and control over SEI layer thickness Furthermore, a

of carbon (the inset in c) and additional PAn

small peak appears at 1.35 V confirms the synergism among

developed N-PGC. It is well-known that NPs size distribution

the CoSnx core and N-PGC matrix It is worth noting that

strongly affects the electrochemical performance and tap

no peak was observed during anodic scan for Co which

density of nanomaterials. To obtain narrow size distribution,

demonstrates its completely inactive nature Moreover,

heat treatment at different rates (2, 5 and 10 1C/min) was

to confirm the high rate capability of hybrid, CV scans at

carried out (). It is scrutinized that

different rates were carried out, as shown in . It is

as heating rate was reduced from 10 to 2 1C/min, size

worth noting that similar profile of CV curves at different scan

distribution became narrower and remarkably carbon shell

rates were obtained, which assures high rate capability of the

formed only at lower heating rate. Furthermore, longer

hybrid and easy access of redox sites due to unique internal

time annealing was also adopted with aim to get rid of oxide

structure. In contrast to hybrid electrode, the electrode of Sn

species but it result in poor size distribution which is not

shows huge difference among first and successive cycles that

suitable for better performance (To further

confirm the formation of very thick SEI layer on the surface of

confirm the structure and existence of electrolyte blockage

electrode and further reduction of current intensity in

layer, high resolution TEM (HRTEM) studies were carried out,

successive cycles confirm the reformation of SEI

from c it can be seen that the surface of NP is

because raptured surface exposed fresh surface of tin that

completely covered by �2.2 nm uniform carbon shell.

increases SEI film thickness via irreversible storage of Li+.

Furthermore, inter-planar distance measurements make

The voltage profiles of hybrid b) exhibited typical

sure the existence of both electrochemically active (Sn)

electrochemical features of CoSn (here broader voltage range

and inactive (Co) metals, the measured d-spacing of

of 5 mV to 3 V was used for the complete exploration of

0.249 nm at position 1 (inset of corresponds to

stability of electrode developed with unique composition but

the (211) plane of CoSn2 (JCPDS no. 25-0256) as shown in

the redox reaction is in the limits of anode cut of voltage)

c. To explore the segregation of multiphase,

with almost no change over 100 cycles. Further,

Control over large-volume changes

(a) Cyclic voltammograms of CoSnx@C–PAn at scan rate of 0.2 mV/s in the voltage range of 0.005–3 V vs. Li+/Li.

(b) Galvanostatic charge–discharge curves of CoSnx@C–PAn hybrid cycled 1st, 2nd, 50th and 100th tested at current density of 0.2 A/gin the range of 0.005–3 V vs. Li+/Li. (c) Cyclic performance, capacity retention and Coulombic efficiency of CoSnx@C–PAn for 100cycles at current density of 0.2 A/g in the voltage range of 0.005–3 V vs. Li+/Li. (d) The cyclic performance and Coulombic efficiencyof CoSnx@C–PAn at different current densities in the voltage range of 0.005–3 V vs. Li+/Li.

absence of large plateaus confirms the faster transfer of

of its first lithiation process and result in capacity of

lithium inside the electrode through porous carbon and grain

2037.8 mAh/g. The loss of 341.6 mAh/g capacity is because

boundaries as proved by HRTEM studies c–e)

of the SEI film formation that was overcame in the next cycles

in contrast to the electrode that shows large irreversible

with improved CE. Furthermore, the plateaus in the first

storage of lithium in the first cycle and in successive cycles

discharge curve well concise with CV curve and show two

required large time to diffuse, resulting poor CRt ().

major changes first the lithium storage through the conversion

Furthermore, it is point of ponder that faster diffusion of

reaction with Sn; second through insertion in the carbon

Li+ is necessary for high rate capability and the linear profile

matrix as indicated by the plateau below 0.5 V that continues

is indication of faster diffusion through shorter distance

till the cut off voltage reaches. Further to explore the

(below 10 nm) . In fact, the grain boundaries serve as

practical utilization of as-developed hybrid, its electrochemi-

tunnels inside the NPs for faster transfer of Li+ and Co

cal performances were explored in various voltage widows

provides faster electron flow to redox sites as results an

(0.005 to 1.5 and 0.005 to 0.6 V) as for practical utilizations

efficient redox reaction happened in a short time, thus result

the upper voltage limit of anode should be restricted below

in linear charge-discharge profile with improved performance

1.2–1.3 V . It is worth noting that hybrid outperformed

as discussed by Gogotsi and Okubo et al. The CE is an

even in the restricted voltage windows and shows the

indicator of the reversibility of the electrochemical reaction

discharge capacities of 1524.76 and 880.12 mAh/g after 100

at electrode . The decrease in CE usually happens due to

cycles with CRt of �99% at current density of 0.2 A/g in the

rupture and reformation of SEI layer, especially in later

voltage range of 0.005–1.5 V and 0.005–0.6 V, respectively as

cycles. After initial few cycles, CE remains nearly 100% during

shown in In addition the CE values reach to 100%

charging and discharging process of the hybrid electrode

after initial few cycles that further emphasized the high

(c and d). It should be noted that low areal mass

reversibility of the hybrid in the restricted voltage windows.

loadings were frequently used to achieve the stable cycling

The stable CE and high CRt demonstrated that hybrid is highly

life. However, high mass loadings are needed to realize the

feasible for deep diffusion of Li+ and all material is active in

high performance for electrification of road market The

thick electrode. To observe the effect of mass loading on the

hybrid shows first discharge capacity of 2379.4 mAh/g with

performance of hybrid 4 electrodes were assembled with

mass loading of 3.8 g/cm2 (further the tap density of the

different mass loadings (2–4 mg/cm2) and it was found that

as-synthesized hybrid is 0.46 g/cm3 and this is in the desirable

increasing mass loading has minimal effect on performance

range for electrode material as Sn based materials show large

. Furthermore, similar performance shows high

volume changes) at current density of 0.2 A/g and capacity

repeatability of the results and further exclude the influence

retention was as high as 100% (calculated from 2nd discharge)

of other factors likewise cell assembly, testing conditions etc.

after 100 cycles. While the hybrid shows 85.64% de-lithiation

Stable structure at particle level is highly required to achieve

N. Mahmood et al.

stable long cycling of a high mass loaded electrode, because

(Rct) were measured using appropriate Randles equivalent

electrode level cracking and failure can be possible even with

circuit shown in The calculated Rf and Rct

small changes in particle morphology which accumulate

before testing is 16.39 Ω and 72.14 Ω that slightly increased to

across the thickness of electrode. A successful design of the

18.53 Ω and 75.14 Ω after 1000 cycles of testing, respectively.

hybrid structure is indicated by stable and excellent perfor-

Vertical spikes confirmed the capacitive behavior of hybrid but

mance at high mass loading. To explore the rate capability,

a little increment in ions diffusion resistance (Warburg impe-

hybrid was tested at various current densities and it is found

dance, W) was observed after long cyclic life. Better electron/

that hybrid keeps its reversibility with changing current

ion conductivity over prolonged cycles with strong resistance

densities as shown by stable CE d). The hybrid keeps

control for successive charge–discharge cycles suggest extra-

its reversible capacity as high as 551 mAh/g at higher current

ordinary CRt, CE and high stability of hybrid. To the best of our

density of 20 A/g and restores its excellent performance of

knowledge, long stable life with excellent performance at such

2040.5 mAh/g with decrease in current density to 0.2 A/g

high mass loadings is rarely reported for Sn-based electrodes.

d). Thus, high rate capability along with higher

Synergistic effect of Co doping, C coating and N-PGC with

performance proves the reliability of the developed method

Sn was analyzed by comparative electrochemical studies of

to control over large volume changes of anode materials.

PAn, Sn, Sn@C, Co2SnO4, Co2SnO4–PAn, CoSnx and CoSnx@C–

Furthermore, hybrid was tested for 1000 cycles at 10 A/g to

PAn. It is simply perceived from that after making

evaluate the long cyclic life of electrode. It is found that hybrid

hybrids of two structures the performance increased, which

keeps a capacity of 956.4 mAh/g after 1000th cycle with high

indicated that materials took successfully the advantages of

CRt of 98.5% (only 0.0015% capacity loss per cycle) and stable

both components for better performance due to strong

CE around 100% The stability of structure after

interfacial interactions. The performance of Sn@C is

electrochemical test was examined through TEM and HRTEM

increased after carbon coating but still a large capacity loss

after washing electrode material with acid to remove SEI layer

was observed in the initial cycles. The fact that increasing

). From microscopic analysis, it is evaluated that the

the electronic conductivity of Sn via carbon coating can

structure (measured d-spacing of 0.199 nm corresponds to (310)

improve the performance through faster Li+ diffusion, but

plane of CoSn2 (JCPDS no. 25-0256)) and size of NPs in hybrid

lithium intercalation reaction (Li4.4Sn) may be limited by

are preserved after long cycling test. Moreover, the stability

electron transfer between the carbon coating and redox site

concern of hybrid was examined by electrochemical impedance

in the crystal It is noticeable that when the intrinsic

spectroscopy (EIS) before and after 1000 cycles .

conductivity of Sn was increased through Co doping, an

Similar Nyquist profile was obtained for hybrid before and after

improved performance was achieved but capacity loss at

1000 cycles as both curves show semicircle in high frequency

initial cycles still exist because of surface reactions. Thus, by

region and a straight vertical inclined line in lower frequency.

combining Co doping and constructing shell of carbon in one

The SEI layer impedance (Rf) and charge transfer resistance

(a) Cyclic performance, capacity retention and Coulombic efficiency of CoSnx@C–PAn for 1000 cycles at current density of

10 A/g in the voltage range of 0.005–3 V vs. Li+/Li. (b) Nyquist plots of CoSnx@C–PAn hybrid before and after 1000 cycles of charge–discharge in the range of 100 kHz to 10 mHz at open circuit potential (the inset is Nyquist plot with equal x–y axis ratio at highresolution). (c) Comparison of discharge capacities of CoSnx@C–PAn, CoSnx, Co2SnO4–PAn, Co2SnO4, Sn@C, Sn and PAn at currentdensity of 0.2 A/g in the voltage range of 0.005–3 V vs. Li+/Li.

Control over large-volume changes

performance is attained with high CRt. Further the incor-

of 3.8 mg/cm2. Furthermore, hybrid shows long cyclic stability

poration of hard Co also prevents the rapture of C shell

for 1000 cycles of charge–discharge at current density of 10 A/g

around the NPs by compensating the internal stresses as over

with capacity of 1256 mAh/g after 1000th cycle and impedance

expansion of NPs causes the rapturing of the C shell It is

calculations confirm slight change in resistances after 1000

worth noting that carbon matrix with well-defined pore size

cycles. The rate capability of the hybrid is explored by testing

(1–1.5 nm) provide highway to both electrons and ions

at different current densities and hybrid keeps 551 mAh/g even

through pore walls and pores, respectively. These pores

at 20 A/g. The approach to build active–inactive metal phase

provide tunnels for deep and fast diffusion of Li+ in thick

encapsulated in carbon shell and embedded in N-PGC adaptable

electrode to keep the entire material active, which is further

matrix established here opens up a new avenue to control

facilitated by the internal grain boundaries of NPs to achieve

volume changes and brings high performance of tin-based

faster redox reaction by shortening the internal diffusion

anode, can also be extended to other attractive anode (like

path. The relative sizes of Li+ ions and pores of the electrode

Silicon, Germanium, etc.) and cathode materials systems that

materials are also very important in determining the poten-

suffer large structural changes during conversion reactions.

tial performance. In our designed system, Li+ (0.076 nm) caneasily diffuse through the electrode materials (pore size

Supporting information

1.5 nm) not only providing higher performance but alsohigher rate capability . In addition, higher capacity

Supporting Information is available from the Elsevier or the

is observed than the theoretical capacity of Sn, this addi-

author [part of experimental section, XRD of PAn before and

tional capacity comes up from the interfacial storage of Li+

after annealing, Raman and FTIR results of hybrid, XRD of Sn

due the existence of mixed phase by space layer charge that

NPs, STEM image of hybrid, TEM images of hybrid, Co

is energetically favorable at interface of two phases as shown

NPs, PAn before and after annealing, hybrid at different

in , intercalation of Li+ in N-PGC through conver-

temperature, high resolution spectra of Sn3d and Co2p, Sn

sion reaction of Lix/C6 that contributes large capacity and

and Sn@C NPs, Hybrid after testing, SAED of hybrid and Sn

synergistic effect between NPs and N-PGC The

NPs, HRTEM, of hybrid after testing, NPs distribution graph,

existence of nitrogen in the carbon make it more electro-

PAn polymerization reaction mechanism, CV of Sn NPs,

chemical active that results higher performance (c)

capacity performance of hybrid at different mass loading,

and contribute lager capacity to hybrid performance. As,

behavior of bulk and nanomaterials towards Li + storage,

nitrogen is capable to change the electronic structure and

Nyquist plot and equivalent circuit diagram].

density of state to improve the conductivity and capacity ofgraphitic carbon To further explore the synergism ofdifferent components, EIS studies were done and represen-

tative Nyquist plots are shown in In the light ofabove results, the optimized cycling stability and rate

This work was supported by the NSFC-RGC Joint Research

capability of hybrid is attributed to the enhanced transport

Scheme (51361165201), NSFC (51125001 and 51172005),

kinetics and structural stability. The high transport kinetics

Beijing Natural Science Foundation (2122022), Aerostatic

comes from N-PGC conductive network that provides faster

Science Foundation (2010ZF71003) and Doctoral Program of

electronic highway from current collector to active material

the Ministry of Education of China (20120001110078).

and among the separated NPs as well as Co improves theintrinsic transfer of electron from carbon to redox sites which

Supporting information

make available all the material for higher performance. Thehomogenously porous structure and anisotropic adhesion

Supplementary data associated with this article can be

realizes efficient mass transfer of Li+. Furthermore, the

found in the online version at

structure is protected via accommodating internal strains by

hard Co, preventing surface reactions by carbon shell andpresence of adaptable matrix of N-PGC.

In summary, CoSnx@C–PAn hybrid has been fabricated utilizing

low-cost and large scale aqueous chemical growth under

industrially acceptable conditions to control large volume

changes and make accessible all active sites of Sn-based anode

via active–inactive metal phase embedded in N-PGC matrix.

The hybrid efficiently took the advantages of mixed phase,

enhanced internal conductivity by hard Co doping, surface

protection by carbon shell and high surface area (438.5 m2/g)

with well-defined pore size (1–1.5 nm) to improve the transport

kinetics, lithium intercalation reaction (Li6/C6) in fused C6

aromatic ring of N-PGC and structural stability. The hybrid

possess high capacity of 2044 mAh/g with extraordinary CE and

CRt of �100% after 100 cycles at 0.2 A/g with the mass loading

N. Mahmood et al.

Nasir Mahmood obtained his BS degree in

2009 in Chemistry from Punjab University

and MS degree in 2011 in Materials and

Surface Engineering from National Univer-

sity of Science and Technology, Pakistan. He

joined Peking University in 2011, where he

is currently pursuing his Ph.D in Materials

Science and Engineering under the guidance

of Prof. Yanglong Hou. His research involves

the synthesis of graphene/graphene-based

nanomaterials and their application in energy storage and conver-

sion devices.

Jinghan Zhu received her B.S. in Materials

Science and Engineering from the University

of Science and Technology Beijing (USTB,

China) in 2011. She has been pursuing her

Ph.D under the supervision of Prof. Yanglong

Hou in the Department of Materials Science

and Engineering at Peking University since

2011. Her research interests are the chemical

synthesis of graphene based nanomaterials

and their magnetic and catalytic applications.

Sarish Rehman obtained his BS degree in

Chemistry from Peshawar University in 2010

and her MS degree in 2013 in Materials and

Surface Engineering from the National Uni-

versity of Science and Technology, Pakistan.

She joined Peking University in 2013, where

she is currently pursuing her Ph.D in Materi-

als Science and Engineering. Her research

focuses on the synthesis and development

of novel nanomaterials for the application

in energy storage and conversion devices.

Quan Li received her Ph.D in Materials Science

and Engineering from Northwestern University

in 2001. She joined The Chinese University of

Hong Kong as an assistant professor in 2002,

and was promoted to full professor in 2011.

Her research focuses on functional materials,

including the fabrication and assembly of

nanomaterials, characterizations and mea-

surements of individual nanostructures, and

their applications in energy and biomedicine.

Control over large-volume changes

Yanglong Hou received his Ph.D in Materials

research interests include the design and chemical synthesis of

Science from Harbin Institute of Technology

functional nanoparticles and graphene, and their biomedical and

(China) in 2000. After a short post-doctoral

energy related applications.

training at Peking University, he worked atthe University of Tokyo from 2002 to 2005 asJSPS foreign special researcher and also atBrown University from 2005 to 2007 aspostdoctoral researcher. He joined PekingUniversity in 2007, and now is a Chang JiangChair Professor of Materials Science. His

Source: http://www.phy.cuhk.edu.hk/qli/publication/2015/Control%20over.pdf

The new england journal of medicine Alastair J.J. Wood, M.D., Editor New Drugs for Rheumatoid Arthritis Nancy J. Olsen, M.D., and C. Michael Stein, M.B., Ch.B. heumatoid arthritis affects approximately 1 percent of the From the Divisions of Rheumatology(N.J.O., C.M.S.) and Clinical Pharmacology

Prevalence of diabetes, obesity, and metabolic syndrome in subjects with and without schizophrenia (CURES-104)Subashini R, Deepa M, Padmavati R1, Thara R1, Mohan V Epidemiology and Background: There are some reports that diabetes and metabolic syndrome (MS) are more prevalent among Diabetology, Madras Diabetes Research schizophrenia patients. However, there are very few studies in India which have estimated the prevalence