Proj.iasri.res.in

ICAR Sponsored

Centre of Advanced Faculty Training in Agricultural Microbiology

Annual Report (2014-15)

Department of Agricultural Microbiology

Directorate of Natural Resource Management

Tamil Nadu Agricultural University

Coimbatore - 641 003

ANNUAL REPORT

Centre of Advanced Faculty Training in Agricultural Microbiology

General information

1.

: Centre of Advanced Faculty Training in Agricultural Microbiology

: Council 's letter number 1-2-/93 (CAS) dated 11-11- 1994 of

Assistant Director General (UNDP), Krishi Bhavan, New Delhi

Date of Inception

Reporting period

Name of the institute

: Department of Agrl. Microbiology

Tamil Nadu Agricultural University Coimbatore 641 003

Name of the Post

Scale of Pay

Sanctioned

Steno cum typist

Rs. 5,200 – 20,200 +

7. Technical programme

To strengthen the UG and PG programme in Agricultural Microbiology To strengthen the research activities in one of the important areas of Agricultural Microbiology. To offer training to scientists and faculty members of state agricultural universities and central

To upgrade the research and teaching facilities in Agricultural Microbiology.

8. Budget allocation and expenditure statement for 2014-15 (Rupees)

Cost of personnel

Training programme

Recurring contingencies

8,54,990

10,12,909

(-) 1,32,909

9. Training programmes to be conducted during 2015-16

Particulars

Training

2nd to 22nd September, 2015

Microbial mediated soil-nutrient transformation

Course coordinators

Dr R.Sridhar, Professor (Microbiology) Dr. T.Kalaichelvi , Professor (Microbiology) Dr. D.Balachander, Professor (Microbiology)

Number of participants

10. List of Topics for Future programmes

Advances in soil biotechnology Antimicrobials from microbial sources and their applications Recent advances in food fermentation Fermented foods and beverages Microbiological techniques for food processing Plant microbe interactions Microbial transformations in soil

ANNEXURE I

Training Details

ICAR-CAF training on

ICAR sponsored Centre for Advanced Faculty Training on

"Biocatalysts for fuels and chemicals from biomass"

(7th to 27th August, 2014)

COURSE OUTLINE

Principles of Biorefining - Biorefinery approaches for fuels and chemicals from crop biomass and

residues - Potential bioresources as future sources of biofuels - Overview of second generation

bioethanol and renewable chemicals from lignocellulosics - Lifecycle assessment of biofuels -

Lignocellulosic bioethanol: Current status and future perspectives – Techno-economic analysis of

lignocellulosic ethanol - Pretreatment technologies for lignocellulose to bioethanol conversion –

Evaluation of physical, chemical and enzymatic pre-treatment technologies – Biocatalysts for biomass

destructions - Production of cellulolytic enzymes for the hydrolysis of lignocellulosic biomass -

Production of hemicellulolytic enzymes for hydrolysis of lignocellulosic biomass - Hydrolysis of

lignocellulosic biomass for bioethanol production - Production of bioethanol from agro-industrial

residues as feedstocks - Fermentation Inhibitors in ethanol processes and different strategies to reduce

their effects – Biomass derived lignin products; Production of biodiesel from algal biomass: Current

perspectives and future - Overview and assessment of algal biofuels - Production technologies -

Cultivation of algae in open systems and photobioreactors for biodiesel production; Production of

Biohydrogen: Current perspectives and future Prospects - Butanol fuel from biomass: revisiting ABE

fermentation - Production of green liquid hydrocarbon fuels – Biomethanation - Biogas production from

anaerobic treatment of agro-industrial wastewater - Biomass gasification: ways of generating biomass

carbon and bio-oil for biofuels production; Thermochemical conversion of biomass to biofuels – Biomass

-derived syngas fermentation into biofuels - The future of biofuels and biofuels of the future.

List of resource personnel

A.

Faculty members

Name and Designation of Faculty

Major areas of research

Dr. S. Gunasekaran,

Fermentation microbiology; Food fortification; Value addition

Professor and Head

of Agricultural products

Biologial nitrogen fixation; Biofertilizer technology;

Diazotrophic diversity; Soil metagenomics; Food fermentation

Dr. R. Murugesan, Professor

Industrial microbiology; Value added products; Antimicrobial compounds; Anaerobes; Biofertilizers

Dr. P. Marimuthu, Professor

Antimicrobial compounds

Dr. K. Ilamurugu, Professor

Soil microbiology; Biological nitrogen fixation; Anaerobes Nanobiosensors

Dr. G. Prasad, Professor

Bioconversion and Environmental microbiology

Dr. K. Vijila, Professor

Food and Fermentation Microbiology; Microbial nutraceuticals and functional foods;

Dr. V. Gomathy, Professor

Solid waste management; Soil aggregation; Liter degradation

Dr.Z.John Kennedy, Professor

Food Microbiology and safety

Dr.N.O.Gopal, Professor

Dr.R.Sridhar,Professor

Food preservation , Probiotics Soil Microbiology

Dr. S. Karthikeyan, Professor

Fermentation technology; Environmental Biotechnology; algal biofuels

Dr. K. Kumutha, Professor

PGPR; AM biofertilizer

Dr. U. Sivakumar, Professor

Lignin degradation; Laccase production; Biofuels

Dr.T.Kalaichelvi, Professor

Biofuels, Forest Microbiology

Dr. M. Senthil Kumar,

Rhizosphere engineering using phages; nanotechnology in food

Assistant Professor

Dr. M. Gnanachitra,

Biofertilizers; formulations and delivery systems

Assistant Professor Dr. R. Subhashini,

Probiotics, Microbial inoculants and formulations

Assistant Professor Dr. R. Brindavathy,

Soil microbiology; PGPR

Assistant Professor

B.

Other scientists of TNAU, Coimbatore

Name and Designation of Faculty

Major areas of research

Biomethanation and bioenergy for rural

Professor & Head, Dept.of Bioenergy,TNAU,

housing and small scale industries

Coimbatore- 3 Dr. R. Murugesan

Bioprospecting microbes for high value

Director,ABD,TNAU,Coimbatore- 3

Nanomaterials and SEM imaging

Professor, Dept. of Nanoscience and nanotechnology Dr. S. Marimuthu

Biopolymers and nanomaterials for value

Assistant Professor, Dept. of Nanoscience and

nanotechnology

C. Experts from other institutions

Name and address

1. Dr.K.Gurumuthy

Former Director, IFGTB, 62/4, Block-2, Second Floor, Leela Apartments, Ponnayarajapuram, Coimbatore-641001

2. Dr.Kalai mathee

Professor & Head, Herbert Wertheim College of Medicine, Florida International University, University Park, Miami, Florida, USA

3. Dr.Palani Shanmugam

Principal Scientist Department of Environmental Technology, CLRI, Adyar, Chennai – 600 020

4. Mr.Sudhagar

DGM , Sakthi Sugars,

Appakudal, Bhavani taluk, Erode

5. Dr. R.S. Prakasham

Sr.Scientist Indian Institute of Chemical Technology Tarnaka, Hyderabad

6. Dr. Mageshwaran V

Scientist Chemical and Biochemical Processing Division, (CIRCOT), Matunga (E), Mumbai-19.

7. Dr. A Uma

Jawaharlal Nehru Technological University Hyderabad Kukatpally, Hyderabad - 500 085, Telangana, India

8. Dr.Annamma Anil

Assistant Professor in Biochemistry DBT-ICT Centre for Energy),Matunga, Mumbai, India

9. Salom Gnana Thanga

Asst. Professor & Head,University of Kerala,Thiruvananthapuram

10. Dr.V.Sivasubramanian

Director - Tech, Phycospectrum Environmental Research Centre 52A, A K Block, 7th Main Road, Anna Nagar, Chennai 600040

11. Dr.S.Seshadri

Shri AMM Murugappa Chettiar Research Centre (MCRC)

Tharamani, Chennai,

Tamil Nadu – 600 113

12. Dr.G.Kalaichelvan,

Senior Professor, VIT, Katpadi, Vellore, Tamil Nadu 632014

13. Dr.Sandeep Mudliar

Principal Scientist, Plant cell biotechnology, CSIR-CFTRI, Mysore - 570 020

14. Dr. Rajeev Kumar Sukumaran

Scientist, Centre for Biofuels, Biotechnology Division, CSIR- National Institute for Interdisciplinary Science and Technology, Trivandrum

15. T. Sivasankar,

Assistant Professor National Institute of Technology, Trichy

16. Dr.Singaravadivel

Professor,Dep. of. Bioenergy, TNAU,Coimbatore- 3

LIST OF PARTICIPANTS

S.No. Name of the participants

Dr. Sunil T. Ingle

Assistant Professor,

Dr. Panjabrao Deshmukh Krishi Vidyapeeth (DPDKV), Akola- 444104

Dr. Santhosh G P

Assistant Professor,

Department of Agricultural Microbiology, Agricultural College, Bheemarayanagudi-585287 Shahapur, Yadgir, Karnataka

Senior Scientist (Microbiology),

Division of Soil Science and Agricultural Chemistry, Indian Institute of Horticultural Research, Hessaraghatta Lake Post, Bangalore-89

Scientist ‘D', Division of Bioprospecting, Institute of

Forest Genetics and Tree Breeding(IFGTB), Forest Campus, R.S.Puram, Coimbatore- 641002

Dr. E.Parameswari

Assistant Professor(Environmental Sciences)

Horticultural College and Research Institute, Tamil Nadu Agricultural University, Periyakulam east, Theni District, Tamil Nadu- 625 604

Dr. R.Uma Sankareswari

Assistant Professor(Agricultural Microbiology)

Department of Soil Science & Agricultural Chemistry Agricultural College and Research Institute, Killilkulam, Vallanad, Tuticorin- 628 252

Dr. S.R. Prabagaran

Department of Biotechnology

Bharathiar University Coimbatore – 641046

Dr. Saravanan V.S.

Department of Microbiology

Indira Gandhi College of Arts and Science Kathirkamam – 605009

ICAR-CAF training on "ICAR – CAF Training on

ICAR sponsored Centre for Advanced Faculty Training on Biocatalysts for fuels and chemicals from biomass

(7th to 27th August, 2014)

Programme schedule

Forenoon

Afternoon

Microbial quorum

sensing for biofilm

Overview of the Biomass feed stock and their issues

development

Biotrap enrichment

training

Dr. Kalai Mathee,

Dr.U.Sivakumar DBT Task force, Coimbatore

International University, Miami

Isolation of cellulolytic,

Inoculation of isolates for cellulase, xylanase,

xylanolytic & ligninolytic

Inaugural function

evaluation

laccase, tyrosinase, xylitol, xylooligosacharide

isolates from enrichment

& lipids production

On site talk and demo of distillery and fermentation plant - Mr.Sudhagar, DGM, Sakthi Sugars, Appakudal, Bhavani Taluk,

Erode dst. Industrial visit

Cellulosic Ethanol: ethanol production:

Imperative role of

Assay of Carbohydrate hydrolytic enzymes

Challenges

pretreatment for

Screening of cellulolytic,

a) cellobiohydrolase, b) endo-1,4-β-D-

sustainable

xylanolytic & ligninolytic

glucanase, c) β-glucosidase and

Dr. R.S. Prakasham

IICT, Hyderabad.

Biodegradation

and growth of

Biocatalysts: An

microorganisms in

overview

substrates

degrading enzymes

Tyrosinase assay

Mageshwaran CIRCOT, Mumbai

Forenoon

Afternoon

Algal biodiesel:

current status

Metagenomic

and future

approaches for biomass

Microbiology lab

prospects

deconstructing enzymes

SDS and Native PAGE of laccase protein

Dr.S.Karthikeyan

Dr.D.Balachander

Professor (AGM),

Professor (AGM),TNAU

Tailoring enzymes for

development of

cellulose based

biocatalysis metagenomics for

hydrolysis and

Dr. Annamma Anil

(Dr.N. Natarajan & Dr. S. Marimuthu)

sugar recovery

DBT-ICT Centre for

Visit to FC & RI, Mettupalayam & Visit to Nilgiris forest, Ooty

Winning project

Bacterial adherence to

proposal

cellulose

& Novel GHs for

Industrial visit - Biopharm

Salom Gnana Thanga,

University of Kerala

Biomethanation: A successful rural

fuel technology

Visit to industrial scale and domestic biogas plants; Biomethane production and

electricity conversion unit, Sempatti and Kinathukadavu

P & H, Dept. of Bioenergy TNAU

Anaerobic

Challenges in

fermentations for

Biobutanol

delignification of

Biomass pre-treatment &

biorefinery

production:

insights

Professor (AGM),TNAU

Dr.S.Karthikeyan

Forenoon

Afternoon

pretreatment by

ultrasonic processing Comp. analysis of lignocell. subst;

Protein purification by FPLC

Saccharification

NIT, TRY

Algal Refinery for

Industrial

Biodiesel producing

value Addition

experience on

biodiesel producing

algal strains

future fuels

algal strains

Dr.T.Kalaichelvi

MCRC, Tharamani,

Dr.T.Kalaichelvi

Enzymatic bio-

refinery for the

sequential

production of

biodiesel,

Lignin derived

production

Biphasic Biobutanol

bioethanol,

products

from starchy

systems/Consolidated

biohydrogen and bio-

Dr.G.Kalaichelvan, photo

methane as an

automotive fuel from Vellore, TN

Mr. Karthikeyan)

tannery solid wastes

Dr.Palani Shanmugam, CLRI, Chennai

Non-chemical wet

oxidation based

pretreatment of

Process design for

crop-residues for

Yeast lipids

biofuel production

bioethanol

Dr. K. Kumutha Professor

production

Asst. Professor, TNAU Dr. Sandeep

Principal scientist, CFTRI, Mysore

Commercialization of

algal biofuels

Breaking the

technology: Industrial

chains in biomass Assay for SSF and SmF

perspective

Dr. Rajeev Kumar

Dr.V.Sivasubramanian

Director - Tech, Chennai

Biohydrogen

Business initiatives for

production

bio-fuel industry

Trainees session

Dr.Singaravadivel

Dr. R. Murugesan

Review by expert, Review by expert,

Valedictory function

Dr. D.J. Bagyaraj

Dr. D.J. Bagyaraj

ANNEXURE II

List of Books Purchased in 2014-15

Name of the Book

Title of the book

Microbial Ecology and

Agricultural Microbiology

Microbial Biodiversity

Gene cloning & DNA

Industrial Applications of

Microbiology Biofertilizers for

sustainable Agriculture

Discount @ 20% 2,873.00

Net amount 11,492.00

Introduction to soil

Net amount special price

5,755.00

33-34-35, Sreeji Apts.,

Biofertilizer Technology

Net amount

6,715.00

Beneficial Plant Microbe

M/s T.R.Publications Pvt Ltd.,

A-32, 3rd floor,

35, South Boag Rd,

Discount @ 20% 3,174.00

T Nagar, Chennai-

Net amount 12,695.00

Food Microbiology

3/5C, Sumitha Nagar,

Umesh Kumar Soil & Agricultural

Microbial genetics

Net amount

3,592.00

NET AMOUNT 34,494.00

(Rupees Thirty four thousand four hundred and ninety four only)

ANNEXURE III

Research Accomplishments/ Salient findings

Effect of long-term nutrient managements on biological and biochemical properties of semi-arid

tropical Alfisol during maize crop development stages-This study has revealed that the overall biological properties of Alfisol were controlled by the long-term nutrient management adoptions and to some epxtend by the growth stages of maize and their interactions.

Under this project, microbial biomass, counts of observed microbial communities and hydrolytic

enzymes were highest in organically managed and integrated nutrient management enforced soils at active vegetative stage of maize crop.

The inorganic nutrient amendments and no fertilizer application had same magnitude on the

biological and biochemical properties of soil throughout the maize crop growth. In general, the amplitude of interaction effect was higher order in OM and INM at vegetative stage than the mean values of the treatments at flowering, harvest and other samples. The respiration study indicates that metabolic quotient of the soil was significantly increased in early stage of maize due to agronomical disturbances and subsequently declined and stabilized during vegetative and flowering stages of maize.

Under the project on ‘Development of process for microbial delignification of lignocellulosic

biomass/waste for fuel ethanol production' a potential laccase producing fungal isolate MSF2 was isolated from wood decay sample was identified which produced higher laccase yield of 1944.44 U.ml-1 in much shorter period (12 days)

A maximum lignin removal of 47.6 and 32.9 % was achieved using a novel biodelignification

process compared to enzymatic removal of 29.7% and 20.22% in wood and corncob, respectively

Higher tyrosinase producing actinobacteria Streptomyces sp JS-8 was isolated

A novel High laccase producing fungi Basidiomycete was identified and characterized

Attempts were made to isolate some thermophilic yeast from Himachal Hot Springs (Manikaran

and Kalath). The positive isolates were further purified and their screening and confirmation of hydrolytic enzyme production is under progress.

Lignin degraders were isolated and selected based on guaiacol oxidation and further confirmed

for their extracellular enzyme production in SEA media containing guaiacol (0.04%).

Lignin depolymerization was carried for kraft and black liquor lignin using crude laccase enzyme

and analysis of lignin derived products using GC-MS is under progress.

Twelve algal isolates viz., Navicula, Unkown diatom, 4 Chlorella sp, Oscillatoria sp, Tolypothrix

sp, Synecococcus sp, Scenedesmus sp, Oedogonium sp, and Spirogyra sp were obtained by enrichment technique. Of which, four dominant, fast growing and lipid rich algal strains viz., Hindakia, Chlorella, Scenedesmus and Chlamydomonad) were identified by phylogenetic studies

The stage-specific inoculants for rice was mass produced and its shelf life was assessed. All the

inoculants has more than 1010 cells per ml. The inoculation of inoculants in the tray-based nursery enhanced the growth and biochemical constituents of rice. Field experiment to assess the impact of stage specific inoculants to rice cultivar ADT45 is in progress.

SCAR Primers designed for detecting Azospirillum strains performed well to discriminate the

target strain from others with very high accuracy and sensitivity. The primers can detect the strains even at low ratio (about 5%) of target in a population.

A simple Sephadex matrix based DNA extraction assay has been developed to elute DNA from

the microbial inoculants with high quality and ready-to-use for PCR.

The MPN-PCR method has low efficient (about 100 times) in detecting the inoculant than

conventional MPN, however, can also used as quality standard, as the detection limit is in the range of inoculant cell load per ml.

The detection limit of SCAR markers to the Azospirillum strains is in the range of 104 cells per ml. Azospirillum (Az 204), Phosphobacteria (Ps1), Potash bacteria (KRB9) and Pseudomonas (Pf1)

were compatible under in vitro condition to develop the liquid bioinoculants. pH of the mixed liquid bioinoculant was slightly reduced from 7.5 to 6.5.

Among the four bioinoculants, population load was slightly reduced in potash bacteria, whereas

the others were not reduced that much.

The effect of fluorescent pigment was very mildly affected the growth of potash bacteria based

on inhibition zone formed in agar well diffusion method and others growth was not affected.

Ten Burkholderia isolates were obtained from the rhizosphere of different crops viz., B1 and R1

were found to have phosphate solubilizing, nitrogen fixing and antagonistic activity against Macrophomina phaseolina.

B1 and R1 were found to produce 36 and 32 mg of P/100 ml broth respectively. B1 and R1 were found to produce IAA 12 and 10 µg/50 ml broth respectively. These two isolates

were identified as Burkholderia thailandensis and Burkholderia vietnamensis.

Shelf life studies of the bacterial consortia experiment revealed that bioinoculants can be stored

upto 120 days under refrigerated storage against 90 days under room temperature.

Field studies at CRS, Aliyar Nagar and ORS, Tindivanam revealed that seed treatment of

groundnut with consortia along with soil application@5Kg/ha on 45 DAS registered the highest pod yield, shelling %, 100 kernel weight and compared to seed treatment alone with soil bacterial consortium.

Gluconacetobacter diazotrophicus was isolated from sugarcane stem and characterized using

standard microbiological techniques

Gluconacetobacter isolate showed better dissolution of phosphate and zinc nutrients

Standardized the protocol for direct shoot induction with modified MS media with BAP 4 ppm+

NAA 2 ppm. Emergence of shoot was observed on 120DAI when compared to other treatments with BAP and NAA.

Average of three to four regenerated plantlets was obtained through this treatment

For in vitro acclimatization, the plantlets were dipped in Methylobacterium bacterial suspension

(108 cells/ml) before planting has better survival than the uninoculated tissue culture plants.

Physico-chemical and biological properties of sago effluent collected from a small scale sago industry (A.R.Durai, ARD with production capacity of <2000kg day-1), a medium scale sago industry (Sree Selliamman Sago, SSS with production capacity of 5000kg day-1) and a larger scale sago Industry (Vel Murugan Sago, VMS with production capacity of >10000kg day-1) during peak season were analysed

When the organically highly enriched sago factory waste waters were channeled through biogas

plants, the pH raised to about 7, the population densities of fermenting and cyanide tolerating bacteria and methanogenic archaea significantly increased, introduced cyanides were consumed, but the BOD decreased only by around 32%, indicating scope for further purification of the sago effluent for safe recycling or reuse

Among the sugars, myo-inositol was found to be highly concentrated in untreated sago

wastewater from all the three sago factories. After biomethanation process, all the sugars were reduced to lower concentration, while the glucose was found to be completely disappeared in the biogas plants of small and large scale factory.

Macronutrients such as potassium, magnesium, calcium and sodium were highly concentrated

in untreated and biomethanated sago wastewater from all the three factories. Among them, potassium was highest in untreated as well as biomethanated wastewater from all the three sago factories. While iron was least in untreated wastewater, it was found to be completely disappeared after biomethanation in all the three factories.

Regarding the micronutrients, zinc was observed to be in higher levels in untreated wastewater,

which completely disappeared during treatment in the biogas plants in all the three factories. Similarly, the concentration of copper completely disappeared during biomethanation of wastewater from the large scale factory.

A total of ten cyanide degrading (CD) bacteria were isolated from the sago wastewater collected

from the three factories using enrichment technique and all the isolates were screened for their ability to utilize cyanide as a nitrogen source.

Five starch degrading (SD) bacterial isolates was isolated from sago wastewater from the three

factories using starch agar media and their starch hydrolyzing ability was determined by observing the clear zone produced in the respective medium when flooded with iodine after 48 h of incubation.

Identified bacteriophages as a new biocontrol agent for the management of soft rot disease

losses under post harvest condition. The technology was standardized for the slow release of bacteriophages when treated with tomato and potato

Technology was optimized for the bacteriophage coating of tomato and potato Entrapment of bacteriophages in a water soluble edible protein for the sustained / slow release

of phages in coated tomato and potato

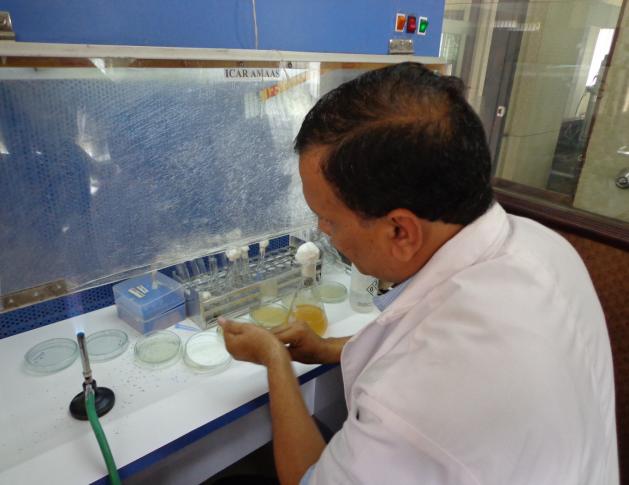

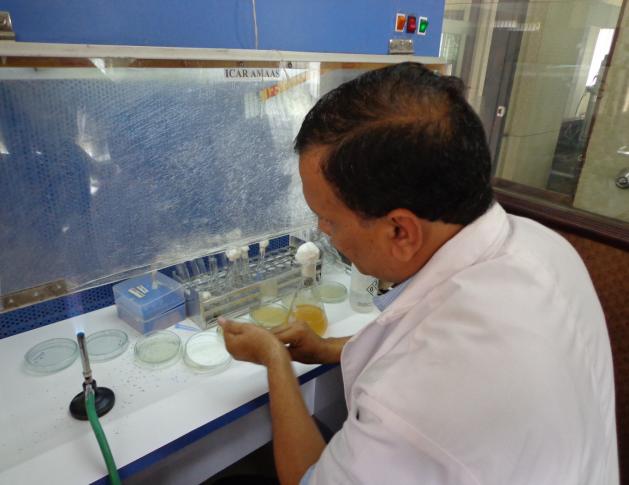

Fig.1. Identification of an efficient lignolytic fungus

ANNEXURE IV

Technology Transfer: Success story

Bacteriophages – A Novel Biopreservative for Vegetables

Bacteriophage based biocontrol measurements have a great potential to enhance

microbiological safety of food at all stages of production in the classic "farm to fork" approach throughout the entire food chain supply system. The bacteriophages are highly host specific in nature, and remain inert unless there is an interaction between host bacteria and phage. To increase the efficiency of the phages and its survival in the fresh vegetables, water soluble, non toxic nano thickness film was developed. The phages were encapsulated in water soluble edible emulsion and fresh vegetables were immersed in the solution for few seconds to form thin film of coating. The treated vegetables were shade dried for 15-30 minutes and can be packed. The water soluble emulsion treated vegetables can be stored for more than 10 days under room temperature depending on the nature of vegetables and fruits. The treated vegetables should be washed in tap water before consumption. The technology is ecofriendly, safe to handle, no residual effect & safe to human consumption. The technology is more useful for farmers, traders retailers & malls. This technology is non toxic to human consumption and can be done either manually or by automation. The technology developed is under progress for standardization of various parameters for further improvement.

Bacteriophage treated potatoes and tomatoes

Novel biodelignification process for lignocellulosic biomass

• Isolated ligninolytic fungi from decayed wood and screened for substrate based laccase enzyme

• The positive isolate MSF2 was identified using 18S rRNA sequencing.

• Enzyme production of MSF2 in a simple medium containing inducer had higher laccase yield of

1944 Uml-1 within a shorter period of 12 days.

• A low cost enzyme production technology was carried using natural lignocellulosic substrates

under Solid (3345.06 Ug-1) and submerged (2666.67 Uml-1) fermentation.

• Delignification process developed using the crude laccase enzyme with solvent recovered a

maximum lignin removal of 48.17 % and 33.81 %, in wood and corncob respectively.

LIQUID BIOFERTILIZER PRODUCTION USING TANGENTIAL FLOW

FILTRATION SYSTEM

is a rapid and efficient method for separation and purification of

biomolecules. TFF can be used to concentrate and desalt sample solutions ranging in volume from 10 mL

to thousands of liters. It can be used to fractionate large from small biomolecules, harvest cell

suspensions, and clarify fermentation broths and cell lysates. There are several options for culture free

techniques (for example, gradient density centrifugation) to concentrate the target to a sufficient level

that is compatible with downstream detection platforms. Although sensitive, techniques such as

centrifugation are expensive and restricted to low sample volumes. In comparison, filtration based

methods do not have a restriction of volumes and use relatively simple equipment that is compatible

with field testing. TFF is a cross flow system that enables high filtration rates of large volumes of sample

without excessive pore blocking as experienced with dead end filtration techniques. In tangential Flow

Filtration, flows are directed across the membrane surface. The sweeping action of the fluid restricts

retained material from settling and eventually reduction flow. It is a pressure driven membrane process

used to concentrate separate or purify macromolecules.

USE OF TFF SYSTEM

• TFF system can filter/separate the microbial cells from liquid broth and concentrate the cells.

• The concentrated cells can be dissolved either in suitable minimal broth or water soluble carrier

• The inhibitory effect of toxic metabolites can be prevented by separation of microbial cells from

the fermentation broth

• Highly suitable for biofertigation • Can be stored for longer period without losing the cell viability

ANNEXURE V

Infra-structures developed

Two 500 litre fermenters were installed to produce liquid biofertilizers to meet the demand

One 62.5 KVA generator was installed to get continuous power supply in the event of power

An air conditioned modern lecture hall with LCD Projectors, Computer with Internet facilities,

Public address systems, TV and DVD players has been developed.

Laboratories have been upgraded for carrying out quality research in leak proof, dust free

and researcher friendly environment.

A library containing about 550 books with browsing facilities for trainees students and staff

has been established under ICAR CAS/CAFT programme at the Department of Agrl. Microbiology, TNAU, Coimbatore.

Following are the equipments available in the department:

Electrophoresis units and

Hofers; Bangalore

Biorad; Bangalore Genei

Refrigerated centrifuge

Microplate reader

Spectrophotometer GC

PCR thermocycler

Eppendorff, Applied

Syngene, UK, Biorad,

Biosystems, Biorad

Fourier Transform-Infra –

Red Spectroscopy

Addition to this, following equipments were purchased in 2013 -15

Instrument

Ultra volume Spectrophotometer

Class II Biological safety cabinet

PCR thermocycler

Applied Biosystems, USA

Incubator Shakers

Orbitec, India; Labcompanion, USA

High temp incubator

Labcompanion, USA

Gel Documentation system

Sample blender for food analysis

Iso Electric Focusing system

Protein Purification system (FPLC)

ANNEXURE VI

Research articles published (2014-15)

Adhilakshmi M, Paranidharan V, Balachandar D, Ganesamurthy K & Velazhahan R (2014)

Suppression of root rot of mung bean (Vigna radiata L.) by Streptomyces sp. is associated with induction of peroxidase and polyphenol oxidase. Arch Phytopathol Plant Protect 47 (5):571-583.

Adhilakshmi M, Latha P, Paranidharan V, Balachandar D, Ganesamurthy K & Velazhahan R (2014)

Biological control of stem rot of groundnut (Arachis hypogaea L.) caused by Sclerotium rolfsii Sacc. with actinomycetes. Arch Phytopathol Plant Protect 47 (3):298-311.

Balachandar D, Doud MS, Schneper L, Mills D & Mathee K (2014) Long-term organic nutrient

management fosters the eubacterial community diversity in the Indian semi-arid alfisol as revealed by length heterogeneity–PCR. Commun Soil Sci Plant Anal 45 (2):189-203.

Bhattacharyya P, Roy KS, Dash PK, Neogi S, Shahid M, Nayak AK, Raja R, Karthikeyan S,

Balachandar D & Rao KS (2014) Effect of elevated carbon dioxide and temperature on phosphorus uptake in tropical flooded rice (Oryza sativa L.). Eur J Agron 53:28-37.

Chinnadurai C, Gopalaswamy G & Balachandar D (2014) Long-term effects of nutrient

management regimes on abundance of bacterial genes and soil biochemical processes for fertility sustainability in a semi-arid tropical Alfisol. Geoderma 232-234: 563-572.

Cibichakravarthy B, Kumutha K & Balachandar D (2014) Arbuscular mycorrhizal fungal diversity

in phosphorus-deficient Alfisols of a dry North-western agro-ecosystem of Tamil Nadu, India. Ann Microbiol:1-11. doi:10.1007/s13213-014-0845-8.

Iniya Kumar Muniraj, Sivakumar Uthandi, Zhenhu Hu, Liwen Xiao, Xinmin Zhan.2015. Microbial

lipid production from renewable and waste materials for second generation biodiesel feedstock. Environmental Technology Review, DOI: 10.1080/21622515.2015.1018340.

Jaivel, N., R. Rajesh, C. Uvarani and P. Marimuthu. 2014. In vitro Antimicrobial Evaluation of

Compound Derived from Streptomyces sp. TC1 against Xanthomonas oryzae pv. oryzae. Journal of Pure & Applied Microbiology, 8(2), 1-12.

Jaivel, N., R. Rajesh and P. Marimuthu. 2014. Evaluation of antimicrobial activity against

bacterial leaf blight pathogen Xanthomonas oryzae pv. oryzae and antioxidant activities of Streptomyces sp. TC1. African Journal of Microbiology Research, 8 (40), 3558-3564.

Jaivel, N., C. Uvarani, R. Rajesh, D. Velmurugan and P. Marimuthu. 2014. Natural occurrence of

organo fluorine and other constituents from Streptomyces sp. TC1. Journal of Natural Products, 77, 2-8.

Jaivel, N., R. Rajesh and P. Marimuthu. 2014. Optimization of Lovastatin Production by

Aspergillus terreus under Various Fermentation strategies. Trends in Biosciences, 7(4), 658-662.

Jaivel, N., R. Rajesh and P. Marimuthu. 2014. Standardizing the extraction and evaluation of

antimicrobial fraction from Streptomyces sp. tc1 against Xanthomonas oryzae pv. oryzae. Life Sciences Leaflets, 54, 16-26.

Khambalkar, P., R. Sridar, M. Sivaji.2014. Isolation and characterization of Plant growth

promoting Rhizobacteria Burkholderia sp. J.Soil Biol.Ecol.34: 1-8

Nikita E. Chavarria, Shiyun Cao, Mary Holman, Dina Elbanna, Suzanne Rodriguez, Deanna

Arrington, Markus Englert, Sivakumar Uthandi, DieterSöll, and Julie A. Maupin-Furlow. 2014. Archaeal Tuc1/Ncs6 homolog required for wobble uridinetRNAthiolation is associated with ubiquitin-proteasome, translation, and RNA processing system homologs. PloS one 9 (6), e99104.

Ponvizhi Ramya, V., S. Gunasekaran and M.Senthilkumar. 2014. Genetic Diversity of soft rot

Pathogens in Potato of South Indian Origin. Research Journal of Biotechnology. Vol. 9 (5) :47-58.

Ponvizhi Ramya, V., S. Gunasekaran and M.Senthilkumar. 2014. Phenotypic identification of sour

rot pathogen of tomato in TamilNadu. Pestology vol. 38 (5) : 11-16.

Priyanka, S., M Sivaji and R Sridar.2014. Isolation and characterization of a novel multifunctional

sulphur oxidizing bacterium (SOB) and its use as biofertilizer. International Science Journal.1:28-34

Rajesh, R., N. Jaivel and P. Marimuthu. 2014. Muntingia calabura botanical formulation for

enhanced disease resistance in tomato plants against Alternaria solani. African Journal of Microbiology Research, 8 (20), 2059-2068.

Rajesh, R., N. Jaivel and P. Marimuthu. 2014. Antifungal metabolite from Muntingia calabura

root against early leaf blight of tomato. Journal of Medicinal Plant Research, 8(13), 523-528.

Rajesh, R., N. Jaivel and P. Marimuthu. 2014. Bioefficacy Muntingia calabura of botanical

formulation against Alternaria solani causing early blight in tomato. Journal of Mycology and Plant Pathology, 44(2), 166-171.

Rajesh, R., N. Jaivel and P. Marimuthu. 2014. Botanical formulation of Muntingia calabura for

the management of early leaf blight in tomato. Madras Agricultural Journal, 100 (1-3), 747-750.

Ramasamy, K., U. Sivakumar and K. Sara ParwinBanu.2014. Unravelling Plant Microbiome:

Proteins and Small Molecules in Signaling and Improving Plant health. Eds: Editor: K.RAMASAMY AND K. KUMAR, Published by NEW INDIA PUBLISHING AGENCY, ISBN: 9789383305834

Sarathambal C, Ilamurugu K, Balachandar D, Chinnadurai C & Yogita Gharde (2015)

Characterization and crop production efficiency of diazotrophic isolates from the rhizosphere of semi-arid tropical grasses of India. Appl. Soil Ecol. 87:1-10.

Selastin Antony, R., G. Gopalaswamy and M. Senthilkumar (2014). Exo polysaccharides

production of brinjal bacterial wilt pathogen Ralstonia solanacearum. Trends in Biosciences 7(16): 2229-2232.

Selastin Antony, R., G. Gopalaswamy and M. Senthilkumar (2014). Characterization of

devastating phytopathogen Ralstonia solanacearum from wilt infected brinjal plants from Mizoram, India. Life Science Leaflets Pp. 6-13.

Shenbagam. P., R. Sridar and M. Sivaji.2014. Developing Rhizobium Mutants for Enhanced

Nodulation in Green Gram Grown in Acid Soils. J.Soil Biol.Ecol.34: 9-16

Sivaji, M., S Priyanka and R Sridar.2014. Isolation and characterization of phosphate solubilizing

Burkholderia sp from crops rhizosphere. J.Innov.Agriculture.1: 1-6

Sivaji, M and R Sridar.2014. Antagonistic activity of Trichoderma viride and Pseudomonas

fluorescens isolated from Bt and non Bt cotton rhizosphere against Rhizoctonia solani. J.Soil Biol.Ecol.34: 60-69

Sivaji, M and R Sridar.2014. Effect of Bt cotton root exudates on functional enzymes in the

rhizosphere soil. J.Soil Biol.Ecol.34: 25-34

Sivaji, M and R Sridar.2014. Impact of Bt Cotton on the Functional Microbes in the Rhizosphere

Under In Vitro Condition. Trends in Biosciences. 7: 3475-3478

Sivakumar Uthandi and G.Kalaichelvan. 2014. Enrichment and Isolation of Bluish Purple

Producing bacterium. J. Soil Biol. Ecol. 34 (1&2) : 17-24.

Srinivasan, M., K.Kumar, K.Kumutha and P.Marimuthu. 2014. Establishing monoxenic culture of

arbuscular mycorrhizal fungus Glomus intraradices through root organ culture. J. Appl. & Nat.Sci., 6 (1):290-293.

Srinivasan, M., K.Kumar and K.Kumutha. 2014. Isolation and selection of efficient AM fungi

spores from sugarcane rhizosphere for in vitro AM inoculum production. Biochem. Cell. Arch., 14 (1): 89-93.

Srinivasan, M., K.Kumar K.Kumutha and P. Marimuthu. 2014. Comparison of colonization

potential of AM fungus Glomus intraradices cultured under In Vitro and In Vivo condition. Trends in Biosciences 7(3): 437-440

Srinivasan, M and K.Kumar. 2014. Production of Daucus carota hairy root for in vitro culture of

arbuscular mycorrhizal fungi., Res. J. Biotech 9(5): 38-41

Srinivasan, M., K.Kumar, K.Kumutha and P. Marimuthu. 2014. Influence of acetosyringone

concentration on induction of carrot hairy root by Agrobacterium rhizogenes., African Journal of Microbiology Research 8(26): 2486-2491

Sujatha, K., K.Kumar. 2014. Biotransformation of cyanide by native bacteria from sago

wastewater under anaerobic condition. Journal of Pure and Applied Microbiology 8(5): 4209-4214

Tamilselvi SM, Chinnadurai C, Ilamurugu K, Arulmozhiselvan K & Balachandar D (2015) Effect of

long-term nutrient managements on biological and biochemical properties of semi-arid tropical Alfisol during maize crop development stages. Ecol Indic 48:76-87.

ANNEXURE VII

Externally funded Schemes obtained in 2014-15

Development of efficient processes for

biomethanation and bioremediation of

cassava sago effluent by nitrogen amendments and Spirulina cultivation under HRAP system for safe recycling DNA fingerprinting of lignocellulose

degrading microbes isolated from

protected forest areas of Assam and Mizoram Evaluation of crop response of liquid

Dr.M.Gnanachitra

inoculants and their effect in rice nutrient

Authentication of recent bioinoculant

2014- 2017 Dr.R.Subhasini

strains of TNAU by physiological and

molecular profiling

Studies on the nutritional/anti nutritional

2014- 2017 Dr.R.Subhasini

changes in finger millet with

thermotolerant Pediococcus pentosauceus

Development of integrated

(biotechnological and nanocatalytic)

biorefinery for fuels and platform

chemicals production from lignocellulosic

biomass (crop/wood residues)' Centre of Excellence on MICROBES TO

Dr. U. Sivakumar

FEED THE WORLD: Plant-Microbe

interactions to boost Agricultural

Dr.D.Balachandar

Dr.K.Kumutha Dr.M.Senthilkumar

Formulation of microbial consortium of

Directorate 6.40

liquid formulation for sustainable

sugarcane production

Molecular detection and quantification of

Dr.D.Balachandar

shiga – like toxin producing Escherichia coli

in fresh vegetables

Lactic acid bacteria of functional interest in

2015-2017 Dr.R.Subhashini

nutrition of finger millet

Patents filed:

1. Sivakumar Uthandi, Sujatha Kandasamy, Iniyakumar Muniraj, Namitha

Purushothaman and Ramasamy Kumarasamy 2015.High level secretion and method

of laccase production by Hexagonia hirta and uses there of (645/CHE/2015)

2. Sivakumar Uthandi, Iniyakumar Muniraj, Anbu P.V, and Ramasamy Kumarasamy

2015. Novel Delignification process for biomass deconstruction of woody biomass and corn cob (under filing)

ANNEXURE VIII

Name of the biofertilizer

Quantity supplied (Kgs)

Amount (Rs.)

Carrier based biofertilizers (Kgs)

Azospirillum

Rhizobium

Azotobacter

Liquid biofertilizer (lit)

Azospirillum

Quality control analysis

Azospirillum

Rhizobium

Azotobacter

Mother cultures supplied

Azospirillum

Rhizobium

Azotobacter

400000/-

805490/-

ANNEXURE IX

ICAR – CAS in Agricultural Microbiology, Tamil Nadu Agrl. University, Coimbatore

List of training programmes conducted from the inception.

Title of the Training

Course Directors

Programme

(Rupees)

1997 - 98 Biofertilizer technology and

Dr P Santhanakrishnan 27.01.97 31.01.97

1997 - 98 Nitrogen fixing and

Dr P Santhanakrishnan

10.10.97 08.12.97

phosphorus Solubilizing microorganisms

1998 - 99 Phosphorus Solubilizing and

21.12.98 03.12.98 17

1998 - 99 Recent trends in symbiotic

Dr S Gunasekaran

01.03.99 14.03.99

Dr P Santhanakrishnan

1999 - 00 Microbial systems

Dr P Santhanakrishnan 01.07.99 15.07.99

1999 - 00 Recent advances in microbial

03.12.99 23.12.99

1999 - 00 Microbial interactions in soil

Dr K. Govindarajan

01.02.00 21.02.00

2000 - 01 Techniques in microbial

01.12.02 21.12.02

Dr V Udayasurian

2000 - 01 Bioconversion of cellulosic

31.01.01 22.01.01

10 2001 - 02 Techniques in Microbiology

11 2001 - 02 Microbial Transformations in

12 2002 - 03 Microbial inoculant

03.02.03 23.02.03

13 2003 –04 Microbial Processes for value Dr R Murugesan

04.02.04 24.02.04

14 2003 –04 Role of Microorganisms in P

03.03.04 23.03.04

nutrition of crop plants

Dr K Govindarajan

Microbial fermentations

Dr S Gunasekaran

01.02.05 21.02.05

16 2004 –05 Molecular techniques in

29.03.05 18.04.05

Dr D Balachandar

17 2005 –06 Recent advances in Microbial Dr T Natarajan

24.03 06 13.04.06

Dr D Balachandar

18 2006 –07 Microbial conversion of

Dr S Gunasekaran

08.11.06 28.11.06

biomass to biomolecules

19 2006 –07 Molecular techniques in

16.01.07 05.02.07

microbial diversity

Dr D Balachandar

20 2007 –08 Microbial products and their

21.01.08 10.02.08

application in food

21 2007 –08 Techniques in soil

09.02.08 29.02.08

microbiology with emphasis

22 2008 –09 Screening and isolation of

Dr G Gopalaswamy

02.11.08 23.11.08

anti-microbial compounds against plant disease

23 2009 –10 Bio-fuels from multiple feed

11.03.09 31.03.09

Dr S Gunasekaran Dr K Kumar

2010 –11 Mycorrhizal systems for

11.03.10 31.03.10

sustainable agriculture

horticulture and forestry

Current Perspectives in

Molecular Microbial Diversity

Microbial processes for value Dr R Murugesan

addition in food and

Dr S Gunasekaran

Microbiological processes in

Dr S Karthikeyan

soil carbon dynamics and

sequestration vis-à-vis

anticipatory climate changes

Faculty Training on Food

Quality and Safety

Dr. Z.John Kennedy

Management systems

Dr.M.Senthilmumar Dr.S.Gunseakran

Biocatalysts for fuels and

Dr.S.Gunasekaran

07.08.14 27.08.14

chemicals from biomass

Dr U Sivakumar Dr S Karthikeyan

Microbial mediated soil-

Dr R.Sridhar, Dr.

nutrient transformation

Dr. D.Balachander

Grants received and expenditure details for the past 15 years (in Rupees)

Source: http://proj.iasri.res.in/cbp/Data/Coordinator/213/Ag.%20Micro%20TNAU%20ICAR%20CAFT%20An%20Report%202014%2015.pdf

Imaginez-vous… Imaginez-vous… ne plus devoir passer du temps à chercher des solutions pour résoudre vos problèmes et passer enfin du temps à faire ce que vous aimez le plus. Imaginez-vous… ne plus devoir expérimenter produits après produits ou régimes après régimes mais atteindre enfin votre plus haut niveau de beauté naturellement pour le reste de votre vie.

EL PROCÉS DE CONSTITUCIÓ DEL BARRI SANTA MARIA DE PALAFOLLS Xavier Gimeno Torrent Protocol de recerca. Abril de 2012. Quan es parla, en aquest país, dels pagesos, es corre sempre el risc —i sobre aquest punt l'experiència és precisa— que se'ns atribueixi una tendència a usar la paraula pagès en el sentit despectiu i grotesc que anys enrera alguns papers humorístics indígenes donaren a la paraula. Aquest sentit despectiu existeix i és corrent trobar-lo entre persones cultivades, en les grans aglomeracions urbanes. En aquestes aglomeracions, s'hi solen trobar de vegades persones accentuadament pedantesques que tendeixen, pel mer fet de respirar, a creure que el seu paisatge urbà —generalment horrible— és el llombrígol del món i el desideràtum de totes les qualitats i de totes les quantitats. Respectem-los les il·lusions, car, si no les tinguessin, els seria massa difícil de resistir el lloc que habiten i la vida que porten.