B8˵Ã÷Êéµ¥

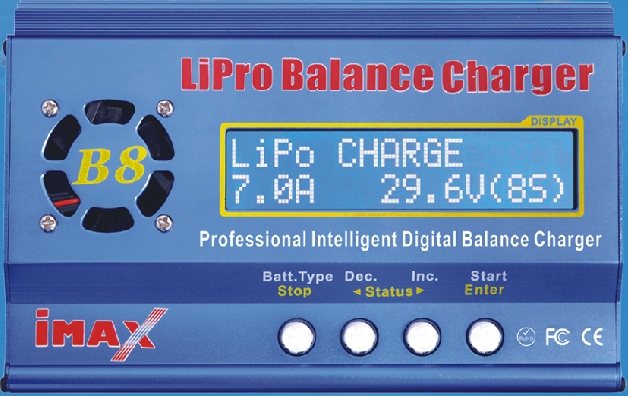

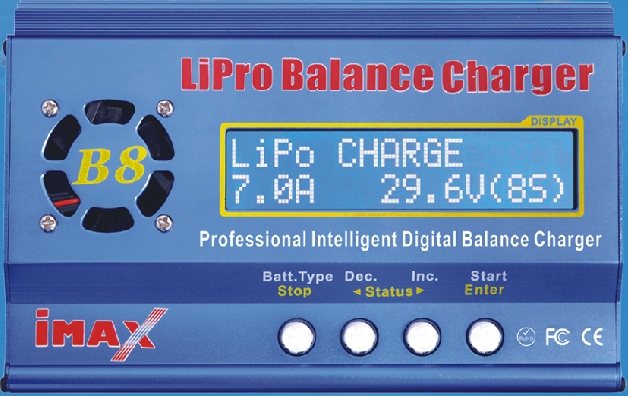

Thank you for purchasing IMAX B8 charger. This is h i g h - s p e e d r e c h a r g e / d i s c h a r g e e q u i p m e n t manufactured with high technology & professional control software. It enables you maintain your battery with optimal status with high level of safety.

Optimized user interface

When charging or discharging, B8 has an

function that sets the feeding

current automatically. Especially for Lithium batteries, it can prevent the over-charging that can lead to an explosion by user's fault. Every program in the unit is controlled with mutual links and communication for every possible error for maximum safety. These can be set at user' s option.

Special recharge plugs port for receiver, transmitter and igniter charger. And for frequently used charger port such as multi purpose crocodile pin etc.

It provides most convenient balance charge port for Lithium batteries, with separated 2,3,4,5,6,7,8 charge port, and external reverse connector.

High-power and high-performance circuit

B8 employs the circuit that has maximum output power of 150W. As a result it can charge or discharge up to 27 cells of NiCd/NiMH and 8 series of Lithium batteries with maximum current of 7.0A. Furthermore the cooling system is so efficient that can hold such a power without any trouble of running the CPU or the operating program.

Individual voltage balance for Lithium batteries inside

B8 has an individual-cell-voltage balancer inside. This does not require any extra balancer when charging Lithium batteries (Lilo/LiPo/LiFe) for cell voltage balancing.

Balance individual cells on discharge

B8 also can monitor and balance individual cells of the Lithium battery pack during the discharge process. If the voltage of nay one cell varies abnormally, the process will be stopped with the error message.

Suitable for various types of Lithium batteries

B8 can accept three types of Lithium batteries-Lilo, LiPo and LiFe. They have different characteristics by their chemistry. You can select any one of them that you are going to process before the job. For their specifications, refer

Warnings and safety notes

Lithium battery

You can charge Lithium battery for special purposes.

charge reduces the

charging time of Lithium battery and

mode controls the final voltage of the

battery to be suit for long time storage.

Delta-Peak Sensitivity: The automatic charge termination program works on the principle of the Delta-peak voltage detection.

Auto-charge current limit: When charging NiCd or NiMH at

you can set the upper limit of charge current to avoid from high current charging. This is very useful when charging the low impedance and small capacity NiMH battery in

The charging capacity always calculated by multiple of the charging

current and time. If the charging capacity exceeds the limit the process will be terminated automatically when you set the maximum value.

Temperature Limit

The temperature of the battery on charging will rise by its internal

chemical reaction. If you set the limit of temperature the process will be expired forcibly when the limit has reached.

Processing Time Limit

You can also restrain the maximum process time to prevent

from any possible defect.

Input Power Monitor To protect the car battery using as input power from being damaged the voltage of it always monitored. If it drops below the lower limit the process will be ended automatically.

For users convenience it can store maximum 10 data of different batteries. You can establish the data contains program setting of the battery to charge or discharge continually. These data can be called out at any time you need and the process can be executed without program setting.

Perform 1 to 5 cycles of charge?discharge or discharge?charge continually for battery refreshing and balancing.

PC based analysis using USB communication

For technical expert, B8 offers PC based program can analysis the characteristic of the battery by USB port. It shows a graph of voltage, current, capacity and temperature curves. It also shows the individual voltage of each cell in the Lithium battery pack.

*PC analysis software and USB Link wire are not included

Five kinds of wires are provided with the B8 charger.You can charge and discharge your battery easily with these wires.

connector(4mm banana female)

Input power cable(dc11 18v)

Individual cellconnector port

Batt type/stop Dec/inc

main program sub program

This diagram shows the correct way to connect your battery to the B6charger while charging in the balance charge program mode only.

WARNING:

Failure to connect as shown in this diagram will damage this charger.

The main battery leads must be connected along with the balance lead connector as shown before charging your battery .

WARNING:

If using crocodile clips as shown in above diagram, make sure they are unable to

touch Together!

Never leave the charger unsupervised when it is connected to its power supply. If any malfunction is observed immediately terminate the process and refer to the operation manual.

Keep the unit away from dust, damp, rain, heat, direct sunshine and vibration. Do not drop it.

The circuit of the unit is designed to be powered by a 11-18 DC only.

This unit and the battery to charge or discharge should be set up on a heat-resistant, non inflammable and non-conductive surface. Never place them on a car seat, carpet or similar. Keep all the inflammable volatile materials well away from operating area.

Cooling vent of charger can not be covered or closed in order to keep good ventilation.

Make sure to completely understand the feature of batteries to be charged or discharged. If the program is set up incorrectly, the battery may be severely damaged. Especially for Lithium battery, it may cause fire or explode if charged incorrectly or overcharged.

Voltage level: 1.2V/cell

Allowable fast charge current: 1C 2C depends on the performance of cellDischarge voltage cut off level: 0.85V/cell(NiCd), 1.0V/cell(NiMH)

Voltage level: 3.6V/cell

Max charge voltage: 4.1V/cell

Allowable fast charge current: 1C or less

Min. discharge voltage cut off level: 2.5V/cell or higher

Voltage level: 3.7V/cell

Max charge voltage: 4.2V/cell

Allowable fast charge current: 1C or less

Discharge voltage cut off level: 3.0V/cell or higher

Voltage level: 3.3V/cell

Max charge voltage: 3.6V/cell

Allowable fast charge current: 4C or less(e.g. A123M1)

Discharge voltage cut off level: 2.0V/cell or higher

Voltage level: 2.0V/cell

Max charge voltage: 2.46V/cell

Allowable fast charge current: 0.4C or less

Discharge voltage cut off level: 1.75V/cell or higher

To avoid short-circuits between the charge lead, always connect the charge cable to the unit first and only then to the batter to be charged or discharged. Reverse the sequence when disconnecting.

Very Important!

Do not connect more than one battery pack to the charge lead at any one time.

The charger is not suitable for the following battery types

Battery pack, which consists of different types of cell (including different manufactures)

Battery which is already fully charged or just slightly discharged

Non-rechargeable batteries (Explosion hazard).

Batteries that require a different charge technique from NiCd, NiMH, Lilo, LiPo, LiFe or Pb.

Faulty or damaged battery

Battery fitted with an integral charge circuit or a protection circuit.

Batteries installed in a device, or which are electrically linked to other components.

Batteries that are not expressly stated by the manufacture to be suitable for the currents the charger delivers during the charge process.

Please bear in mind of checking the following point before

charge operation:

Did you select the appropriate program, which are suitable for the type of battery?

Did you set up adequate current for charging or discharging?

Lithium battery pack can be composed with parallel and series circuits mixed. You have to check the composition of the battery pack carefully before charging

Are all connections firm and safe, or is there an intermittent contact at any point in the circuit?

Charging

A specific quantity of electrical energy is fed into the battery during charge process. The charge quantity is calculated by multiplying charge current by charge time. The maximum permissible charge current varies according to the battery types or its performance, and can be found in the information provided by the battery manufacture. It is only allowed to charge batteries at rates higher then the standard charge current if they are expressly stated to be capable of quick-charge.

Connect the battery to charge to output terminal of the charger using suitable charge

lead. They are red, positive (+) and black, negative (-). Since the charger cannot detect the difference between the internal resistances of the battery pack, cable resistance and connector transfer resistance, the first requirement if the charger to work properly is that the charge lead should be of adequate conductor cross-section. And also high-quality connectors (normally gold-contact type) must be fitted to both ends.

Refer to the information provided by the battery manufacture regarding charging methods, and verify the recommended charge current and charge time. Especially for Lithium batteries, you have to follow the charge instruction provided by the manufacturer strictly.

Do not attempt to disassemble the battery pack arbitrarily.

You have to pay attention to verify the capacity and the voltage of the Lithium battery pack. It may be composed of parallel and series connection mixed. In parallel link the capacity of the battery pack is multiplied by the number of cells but the voltage remains the same. That kind of voltage imbalance causes a fire or explosion during charge process. We recommend you compose the Lithium batter pack in series only.

Discharge

The typical purpose of discharge is to determine the residual capacity of the battery, or to lower the voltage of battery to a defined level. When you discharge the battery you also have to pay attention on the process same as charging. To avoid the battery becoming deep-charged, set the final discharge voltage correctly. Lithium batteries should not be deep-charged to lower than the minimum voltage, as this leads to a rapid loss of capacity or a total failure. Generally, you do not need to discharge Lithium battery voluntarily.

Some rechargeable batteries are said to have a memory effect. If they are partly used and recharged before the whole charge is drawn out, they

time will only use that part of their capacity. This is a

memory effect NiCd and NiMH

batteries are said to suffer from memory effect. They prefer complete cycles; fully charge then use until empty, do not recharge before storage-allow them to self-discharge during storage. NiMH batteries have less memory effect than NiCd.

The Lithium battery prefers a partial rather than a full discharge. Frequent full discharges should be avoided if possible. Instead, charge the battery more often or use a larger battery.

The brand-new NiCd battery pack is partially useful with its capacity until it has been subjected to 10 or more charge cycles in any case. The cyclic process of charge and discharge will lead to optimize the capacity of battery pack.

Those warning and safely notes are particularly important.

Please follow the instructions for a maximum safely; otherwise

the charger and the battery can be damaged violently. And also

it can cause a fire to injure a human body or to lose the property.

B8 will be operated with the default value of the essential user settings when it is connected to a 12V battery for the first time. The screen displays the following information in sequence and the user can change the value of parameter on each screen.

When you are willing to alter the parameter value in the program, press start/enter

key to make it blink then change the value with Inc> or <Dec key. The value will be

stored by pressing start/enter key once.

This informs you of its designation.

The screen displays the nominal voltage of Lithium battery. There are three kinds of Lithium battery: LiFe(3.3V), Lilo(3.6V) or LiPo(3.7V). This is very

important so you have to check the battery carefully and set it up correctly. If it is different from correct value the battery explode during charge process.

B8 recognize the cell count of Lithium battery automatically at the beginning of charge or discharge process to avoid from erroneous setting

by user. But deeply discharged battery can be

perceived incorrectly. To prevent the error, you can set the time term to verify the cell count by the processor. Normally, 10 minutes are enough to perceive the cell count correctly. For the battery of larger capacity, you may extend the time term. But if you set the time term to long for the battery of smaller capacity, the charge or discharge process

can be finished within the time term with the erroneous cell count. This may cause the fatal result. If the processor recognizes the cell count incorrectly at the beginning of charge or discharge process, you may extend the time. Otherwise, you had better use with the default value.

This shows the trigger voltage for automatic charge

termination of NiMH and NiCd battery. The effective

value ranges from 5 to 20mV per cell. If the trigger voltage is set higher, there is a danger of overcharging the battery; if it is set lower, there is a possibility of premature termination. Please refer the technical specification of the battery. (NiCd default: 12mV, NiMH default: 7mV)

An optional feature using temperature probe contacting the surface of battery, the temperature cut-off can be on or off. If it is on, set the maximum temperature at which the charger should allow battery to reach during charge. Once a battery reaches this temperature during charge, the

process will be terminated to protect the battery.

The battery is on the cyclic process of charge and

discharge can often become warm after charge or discharge period. The program can insert a time delay to occur after each charge and discharge process to allow the battery adequate time to cool down before being subjected to the next process. The value ranges from 1 to 60 minutes.

You can set the trickle charge mode on or off. If it is on, the charger will automatically supply the trickle charge current to achieve the full charge without overheating the battery after fast charge has been terminated.

When you start a charge process, the integral safety timer automatically starts running at the same time. This is programmed to prevent overcharge the battery if it proves to be faulty, or if the termination circuit cannot detect the battery full. The value for the safety timer should be generous enough to allow a full charge of the battery.

This program sets the maximum charge capacity that will be supplied to the battery during charge. If the delta-peak voltage is not detected nor the safety timer expired by any reason, this feature will automatically stop the process at the

selected capacity value.

The beep sounds at every time pressing the buttons to confirm your action. The beep or melody sounded at various times during operation to alert different mode changes. These audible sounds can be turned on or off.

This program monitors the voltage of input battery. If the voltage drops below the value you set the operation forcibly terminated to protect the input battery.

You can adjust the brightness of LCD screen at

the charger.

These programs are only suitable for charging and discharging Lithium batteries with a nominal voltage of 3.3V, 3.6V and 3.7V per cell. These batteries need to adopt different charge technique that is termed a constant voltage (CV) and constant current (CC) method. The charge current varies according to the battery capacity and performance.

The final voltage of charge process is also very important; it should be precisely matched with the charade voltage of the battery. They are 4.2V for LiPo, 4.1V for Lilo, and 3.6V for LiFe. The charge current and nominal voltage as for cell count set on the charge program must always be correct for the battery to be charged.

When you are willing to alter the parameter value in the program, press start/enter key to make it blink then change the value with Inc> or <Dec key. The value will be stored by pressing start/enter key once.

The left side of the first line shows the type of battery you select at the users setting. The value on the left side of second line sets a charge current

and the value on the right side of second line sets the voltage of the battery pack.

After setting the current and voltage press

Start/Enter key for more than 3 seconds to start the

process. (Charge current: 0.1 0.7A, Voltage: 1 8

Batt type Start >3seconds

This shows the number of cells you set up and the processor detects.

shows the number of cells

found by the charger and

is the number of

cells selected by you at the previous screen. If both

numbers are identical you can start charging by

pressing Start/Enter button. If not press Batt

type/Stop button to go back to previous screen.

Then carefully check the number of cells of the

battery pack to charge again.

The screen shows the present situation during

charge process. To stop charging press Batt

type/Stop key once.

The charging current is getting smaller as the process goes to the near end term of Lithium battery charging. To finish charging process earlier, this program eliminate certain term of CV process. The charging current will goes to 1/5 from the initial value to end the process while the normal charging goes to 1/10 during CV term. The charging capacity may be a bit smaller than normal charging but the process time will be reduced.

You can set up the charging current and the

voltage of the battery pack being charged. As you

press Start/Enter button the voltage confirmation

will be displayed. And then, if you confirm the

voltage and current, press Start/Enter button

again to start charging.

Batt type Start >3seconds

This shows the present state of

charging. To stop charging arbitrary, press Batt

type/Stop key once.

voltage ofbattery

This is for charging or discharging Lithium battery not to be used for the time being. The program will determine to charge or discharge the battery to the certain voltage depending on the voltage of the battery at its initial stage. They are different from the type of the batter, 3.75V for Lilo, 3.85V for LiPo and 3.3V for LiFe per cell. If the voltage of battery at its initial stage is over the voltage level to storage. The program will start to discharge.

You can set up the current and the voltage of the battery pack to be charged. The current will be used for charge or discharge the battery to reach the

level of voltage.

Batt type Start >3seconds

The screen shows the present situation during

charge process. To stop charging press Batt

type/Stop key once.

discharge batterycurrent

The value of discharge current on the left side of screen may not exceed 1C for a maximum safety and the final voltage on the right should not be under the voltage level that is recommended by the battery manufacture to avoid deep

To start to discharge press Start/Enter key for

more than 3 seconds.

Batt type Start >3seconds

(Discharge current:0.1 5.0A)

This shows the present state of discharge. To

stop discharging press Batt type/Stop key once.

The processor monitors the voltage of individual cells during

of Lithium battery pack. It tries to normalize the voltage to be equal. For

this feature, the individual plug of the battery pack should be connected to the individual port of the charger.

If the voltage of an one or more cells varies abnormally during the procedure, B8 terminates the process forcibly with the error messages. If this happens, the battery pack contains the bad cell, or the bad connection of the cable or plug. You can easily know which one cell is bad by pressing Inc> button at time of showing the error messages.

The processor found that the voltage of one of the cell in the Lithium battery pack is too low.

In this case, the 4th cell is bad. If there happen the connection-break of the cable or plug, the voltage value may show zero.

These programs are for charging or discharging NiMH(Nickel-Metal-Hydride) or

NiCd(Nickel-Cadmium) battery commonly used for R/C model applications. To alter the

value at the display, press Start/Enter key to make it blink then change the value using

Inc> or <Dec kep. The value will be stored by pressing Start/Enter key once.

To start the process, press Start/Enter button for more than 3 seconds.

This program simply charges the battery using the current you set. In

mode,You need to

set the upper limit of charge current to avoid from higher feeding current that may damage the battery. Because some batteries of low

impedance and small capacity can lead to the higher charge current by the processor at automatic charge mode. But in

will charge the battery with the charge current

you set at the display. Each mode can be switched by pressing Inc> and <Dec button simultaneously when the current field is blinking.

The screen displays the current state of charging. To stop the process, press Batt type/Stop key once. The audible sound indicated you the end of process.

Set discharge current on the left and final voltage on the right. The discharge current ranges from 0.1 to 5.0A and the final voltage ranges from 0.1 to 30.0V. to start the process, press Start/Enter key for more than 3 seconds.

Batt type Start >3seconds

The screen displays the current state of discharge. You can alter the discharge current by pressing Start/Enter key during the process. Once you change the current value, store it by pressing Start/Enter button again. To stop discharging press Batt type/Stop key once. The audible sound indicates you at the end of process.

Set the sequence on the left and the number of cycle on the right. You can use this function for balancing, refreshing and break-in the battery. To avoid rising temperature of the battery, there will be a brief cool-off period that already fixed at

after each charge and discharge process.

The cycling number ranges from 1 to 5.

Batt type Start >3seconds

To stop the process, press Batt type/Stop key

once.

You can change the discharge or charge current by

pressing Start/Enter key once during the process.

The audible sound indicates you the end of process.

discharge discharge

At the end of the process, you can see charged or

or charge or charge

discharged electric capacities of the battery at

each cyclic process. By pressing Inc> or <Dec

button, the screen shows the result of each cycle in

order.

This is programmed for charging Pb(lead-acid) battery with nominal voltage from 2 to 36V. Pb batteries are totally different from NiCd or NiMH batteries. They can only deliver relatively lower current compare to their capacity, and similar restrictions definitely apply to charge. So the optimal charge current will be 1/10 of the capacity. Pb batteries must not be charged rapidly. Always follow the instruction is supplied by the manufacture of battery.

When you are willing to alter the parameter value in the program, press Start/Enter key to make it blink then change the value with Inc> or <Dec key. The value will be stored by pressing Start/Enter key once.

Set up the charge current on the left and the nominal voltage of the battery on the right. The charge current ranges from 0.1 to 7.0A and the voltage should be matched with the battery being charged.

Start the charge process by pressing Start/Enter key for more than 3 seconds.

Batt type Start >3seconds

The screen displays the state of charging process. To stop charging forcibly, press Batt type/Stop key once. The audible sound indicates you at the end of process.

Set discharge current on the left and final voltage

on the right. The discharge current ranges from

0.1 to 5.0A. To start the process, press

Start/Enter key for more than 3 seconds.

Batt type Start >3seconds

The screen displays the current state of

discharge. You can alter the discharge current by

pressing Start/Enter key during the process.

Once you change the current value, store it by

pressing Start/Enter button again.

To stop discharging press Batt type/Stop key

once. The audible sound indicates you at the end

B8 has a data storage and load program for your convenience. This feature can store

up to 10 battery data by number that represent the individual specification of batteries

you are using. They can be called back for the process of charging or discharging

without setting up the program again. To set up the parameter value in the program,

press Start/Enter key to make it blink then change the value with Inc> or <Dec key.

The parameter value setting up in this screen does not affect charge or discharge process. They only represent the specification of the battery. The

following screens will automatically be displayed exactly matched with the battery type you set up.

The example shows the battery pack of NiMH, 12

cells and 3000mAh of capacity.

Batt type Start >3seconds

Set up the charge current for manual charge mode,

or the current limit for automatic charge mode. Each

mode can be switched by pressing Inc> and <Dec

button at the same time when the current field is

blinking.

Setting up discharge current and final voltage

Setting up the sequence of charge and discharge, and the cycling number

Start >3seconds

This program calls back the data that was stored at

To load the data, press Start/Enter key once to blink the data number field and select

the number using Inc> or <Dec key then press Start/Enter key for more than 3 seconds.

Select the data number to be called back.

The data matched with the number will be displayed at this time.

Start >3seconds

Loading the data.

You can inquire various information on LCD display during charging or discharging

process. When you press<Dec button the charger shows the establishment of user

settings. And also you can monitor the voltage of individual cell by pressing Inc> button

when the individual connection cable is linked to the Lithium battery being processed.

The final voltage will be reached at the end of process.

The internal temperature of the charger and the temperature of battery being charged.

(The external temperature only will be displayed

when using the thermal probe.)

The present voltage of input DC power.

Using the individual connection cable to the battery, you can check the individual voltages of each cell in the battery pack. When connect the

cable to the port on the right side of the charger the program shows them for maximum 8 cells in sequence. To utilize this feature, the battery pack must have output connector that linked to each cells.

B8 incorporates a various functions of protective and monitoring the system to verify

functions and the state of its electronics. In any case of occurring error, the screen

displays the cause of error that is self explanatory with audible sound.

The output is connected to a battery with incorrect polarity

This will be displayed in case of detecting an interruption of the connection between battery and output or voluntarily disconnecting the charge lead during the operation of charge or discharge on output.

A short-circuit at output. Please check the charging leads.

The voltage of input power drops below the limit.

The voltage of Lithium battery pack was selected incorrectly. Verify the voltage of battery back carefully.

There happens the malfunction at the charger circuit by any reason.

The processor detects the voltage is lower

than you set at Lithium program. Please check

the cell count of the battery pack.

The processor detects the voltage is higher

than you set at Lithium program. Please check

the cell count of the battery pack.

The voltage of one of the cell in the Lithium

battery pack is too low. Please check the

voltage of the cell one by one.

The voltage of one of the cell in the Lithium

battery pack is too high. Please check the

voltage of the cell one by one.

There is bad connection at the individual

connector. Please check the connector and

cables carefully.

The internal temperature of the unit goes too

high. Cool down the unit.

The processor can not continue to control the

feeding current by any reason. The unit needs

to be repaired.

Operating voltage range: 10.0 18.0Volt

Circuit power: max. 150W

Charge current range: 0.1 7.0A

Discharge current range: 0.1 5.0A

Current drain for balancing Li-Po: 300mAh/cell

NiCd/NiMH battery cell count: 1 27 cells

Lithium bettery cell count: 1 8 Series

Pb battery voltage: 2 to 36V

Weight: 574g(Net Weight)

Dimensions: 170X110X35mm

We warrant this product for a period of one year(12 months) from the date of

purchase. The guarantee applies only to such material or operational

defects, which are present at the time of purchasing the product. During

that period, we will repair or replace without service charge any product

deemed defective due to those causes. You will be required to present proof

of purchase (invoice or receipt). This warranty does not cover the damage

due to wear, overloading, incompetent handling or using of incorrect

accessories.

All specifications and figures are subject to change without notice.

Printed in China 2007

Source: http://www.rcfm.cz/domains/rcfm.cz/index.php?option=com_phocadownload&view=category&download=19:Nab%C3%ADje%C4%8Dka%20MAX%208B&id=2:navody&Itemid=561

Pré-ASTERIDAE CORNALES ERICALESASTERIDAE I GARRYALES Blackstonia, Swertia, - 1 - LAMIALES SOLANALESASTERIDAE II APIALES AQUIFOLIALES ASTERALES DIPSACALES - 2 - Ordre des GENTIANALES Pas mal de ligneux tropicaux. Leur unité est basée sur le fait que ces plantes réalisent la synthèse d'alcaloïdes qui résultent de la condensation du tryptophane et d'un reste isoprénique provenant d'un iridoïde, le loganoside. Les fleurs sont généralement régulières, en préfloraison tordues ou valvaires. Souvent de type 4 par réduction évolutive. L'ovaire supère chez les Apocynacées (qui incluent les Asclépiadacées) devient infère chez les Rubiacées.

Using care pathways to improve health systems Care pathways enable health systems (and other health care organizations) to make evidence-based decisions about where to focus improvement efforts. Olivia Cavlan, MD; One of the core missions of any health care for more severely ill children, and palliative Penny Dash, MD;